Product Description

High-performance imported processing equipment and measuring equipment.

Good at processing parts with small tolerances and complex structures, suitable for small and medium-sized batch order production.

Many years of experience in European and American customer service, familiar with national industry standards, such as ISO2768, DIN7168, MIL-55414

Finished product assembly experience, responsible for helping European customers with the procurement, quality control, warehousing, production, product assembly, and finished product testing of more than 1,000 seed parts.

Cases

Optical parts

Difficulty requirements: The parallelism of the inner cavity is required to be 0.02mm, the position of all surfaces and holes is required to be 0.02, and 5-axis processing is required to be completed at one time

Processing technology: CNC three-axis milling + CNC 5-axis milling + CNC 3-axis milling + deburring + FQC + chrome yellow + IOC + shielding + hard anode + IQC + assembly of wire screw sleeves + full inspection + packaging + OQC

Pneumatic tool parts

Difficulty requirements: Spline and long axis are processed at the same time, and the radial runout of the tooth and long axis is 0.04mm

Processing technology: Quenching and tempering + CNC turning + five-axis turning and milling center (spline) + FQC + heat treatment carburizing + IQC + CNC turning including drilling deep holes + FQC + external cylindrical grinding + IQC + cleaning + packaging + OQC

Medical equipment parts

Difficulty requirements: The tolerance of the inner hole segment diameter is 0.015; the position of the side holes around is 0.025; in addition to the go and no-go gauge inspection, the external thread needs to inspect the thread middle diameter, pitch, and tooth angle; it needs to be processed by a CNC lathe with a tailstock and a CNC lathe with side milling

Processing technology: CNC turning + CNC turning and milling composite processing + deburring + FQC + surface treatment + IOC + packaging + OQC

Mineral machinery parts

Difficulty requirements: Inner and outer diameter tolerance requirements of 0.005

Processing technology: CNC turning and milling composite processing + CNC turning + four-axis CNC milling + deburring + FQC + heat treatment + IQC + inner and outer cylindrical grinding machine processing + cleaning + FQC + packaging + OQC

Petroleum machinery parts

Difficulty requirements: heavy cutting volume, inner and outer diameter tolerance requirements of 0.015

Processing technology: CNC lathe + CNC lathe + CNC milling + CNC milling + deburring + FQC + surface treatment + IQC + packaging + OQC

Communication cavity parts

Difficulty requirements: Thin-walled parts are easy to deform during processing, and high requirements for flatness and verticality

Processing technology: CNC milling + CNC milling + CNC milling + deburring + FQC + surface treatment + IQC + packaging + OQC

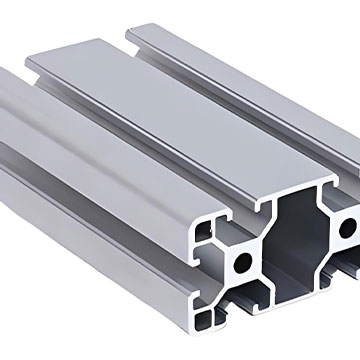

Raw material

Stainless steel

Chromium

Alloy steel

Aluminum alloy

Carbon steel

Copper alloy

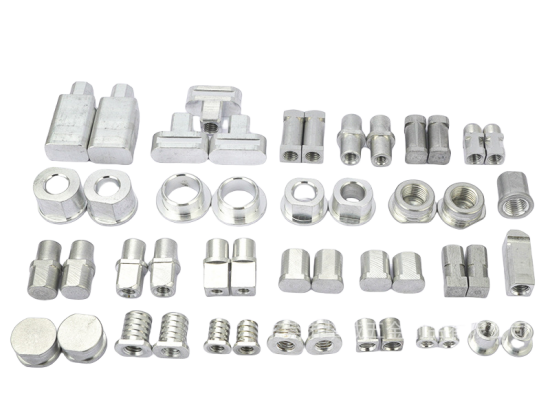

Product parameters

Raw materials | Aluminum alloy, copper alloy, stainless steel, carbon steel, alloy steel, chrome, etc. |

Processing equipment | 5-axis CNC machining center, CNC turning and milling compound machining center, internal and external cylindrical grinder |

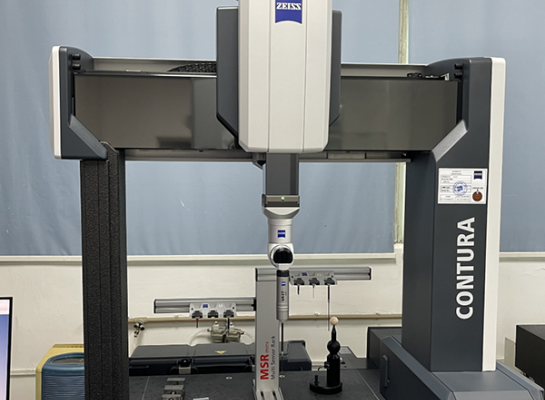

Testing equipment | CMM three-dimensional, two-dimensional, projector, altimeter, roughness meter, micrometer, caliper and various thread plug gauges, ring gauges |

Technology | Casting, forging, powder metallurgy, extrusion, etc. |

Surface treatment | Surface treatment, heat treatment, spraying, dust-free cleaning, etc. |

Application areas | Optics, medical, communication, automobile, power tools, petrochemical and other fields |

Geometric tolerances | Positioning | Parallelism | Coaxiality | Perpendicularity | Total runout | Symmetry | Flatness | Cylindricity | Roundness | Roughness |

Processing accuracy | 0.03 | 0.005 | 0.005 | 0.01 | 0.01 | 0.01 | 0.002 | 0.01 | 0.005 | Ra 0.4 |

Measurement accuracy | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | Ra 0.01 |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test before packing

8. Shipping & confirmation

Production process

Multi-task CNC turning integrates advanced CNC and precision machinery. Turning can quickly change tools, and gear production strictly controls precision, laying the foundation for stable operation of machinery.

The two spindles of the dual-spindle turning and milling center work together, and both ends are processed in one clamping. It is multifunctional and suitable for complex parts processing in multiple fields.

The four-axis CNC machining center has four-axis linkage, combines precision machinery and CNC technology, and can accurately process complex structures. It is easy to operate and efficient, and plays a key role in multiple industries.

The core-walking machine uses a unique feeding method and relies on a high-precision CNC system to achieve one-time precision processing of complex parts. It is widely used in industries with high precision requirements.

The CNC workshop is equipped with multiple high-performance equipment, which can accurately complete various complex processing and continuously provide high-quality products for multiple fields.

Quality Control Equipment

The three-dimensional coordinate measuring machine relies on XYZ three-axis linkage and high-precision probes to accurately measure the size, shape and position of workpieces, and is widely used in quality inspection in multiple industries.

The spectrometer analyzes the spectrum of materials and quickly identifies and quantifies the elemental composition. It is used in multiple fields such as material research and development and quality control.

High-precision microscopes provide high resolution with top-level lenses to magnify tiny objects. They are suitable for research and quality control in scientific research, medical and other fields.

The material composition detector accurately analyzes the elemental composition of materials and provides key data for material research and development and quality control in multiple fields.

Additional Process

The ultrasonic cleaning line uses advanced ultrasonic technology to penetrate deep into the gaps to shake off dirt, and multiple tanks complete pre-washing and other processes in sequence. It is suitable for cleaning parts in multiple industries, with simple operation and high efficiency.

The laser marking machine uses high-energy laser beams to accurately etch on the surface of various materials to form clear and wear-resistant marks. It has fast marking speed and high precision, meets customized needs, and is widely used in multiple industries to improve product recognition.