Product Description

This robot arm electric gripper is made of high-strength wear-resistant material, which is impact-resistant and wear-resistant, ensuring long-term stable operation. Equipped with a precise drive system, it achieves millimeter-level grasping accuracy and is flexibly adapted to a variety of materials such as industrial parts and logistics packages. The exquisite structural design can be easily integrated into the automated production line, efficiently completing assembly, sorting and other tasks, providing reliable support for robot automation operations, and is an optimal accessory for improving industrial efficiency.

Product parameters

Item | Value | Item | Value |

Total Stroke | 120mm (adjustable) | Power | 10W |

Clamping Force | 40-130 N (adjustable) | Operating Voltage | 24V ± 10% |

Recommended Clamping Weight | ≤1kg | IP Rating | IP20 |

Repeatability | ± 0.02mm | Motor Type | DC brushless |

Minimum Time of Single Stroke | 0.9s | Operating Temperature Range | 5~5℃ |

Transducer Type | Screw + connecting rod mechanism | Operating Humidity Range | 35~ 80% RH (frost-free) |

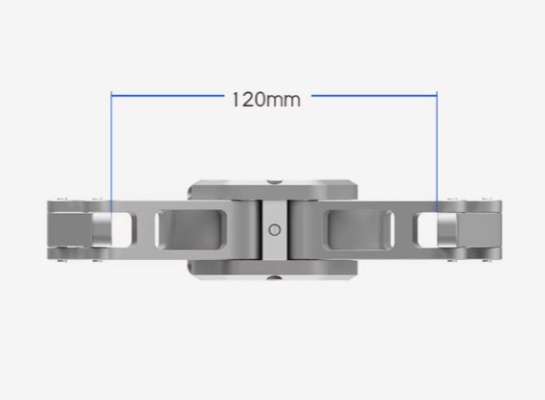

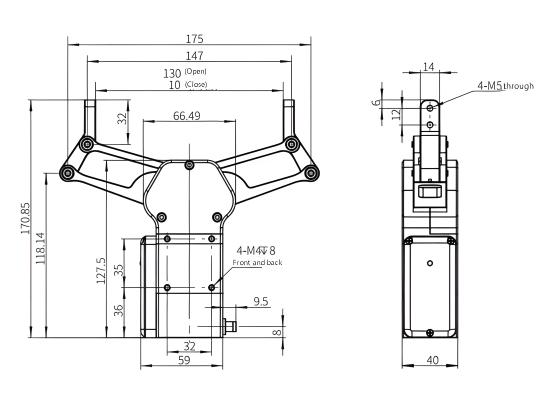

Oil Replenisher for Dynamic Components | Every six months or every dynamic 1 million | Dimensions (L*W*H) | 171*181*40mm (open) |

Gripper weight | 0.8kg | 218+66.5*40mm (closed) | |

Motion Type | Two fingers parallel |

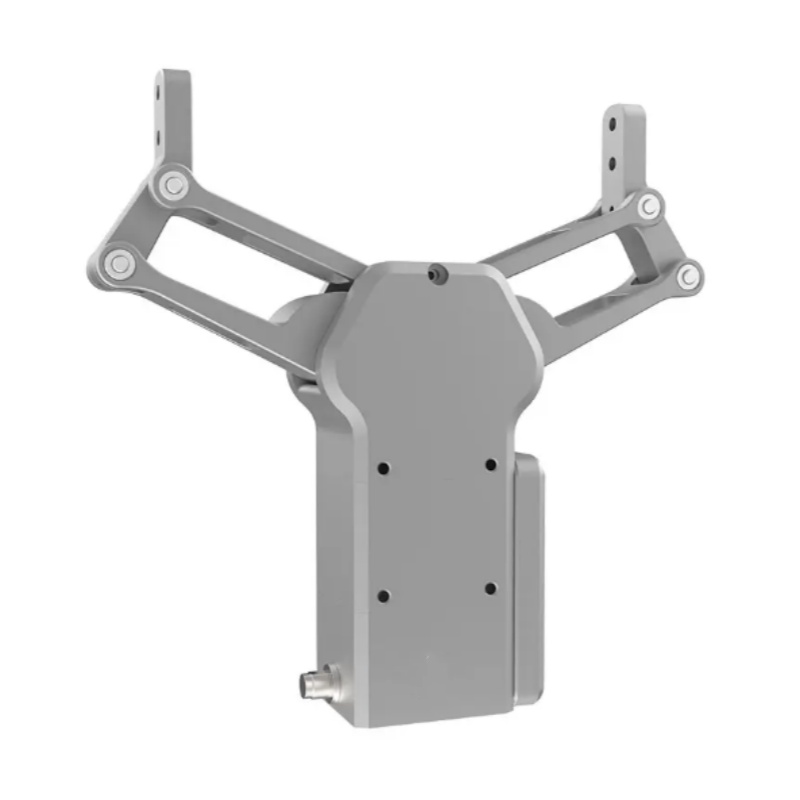

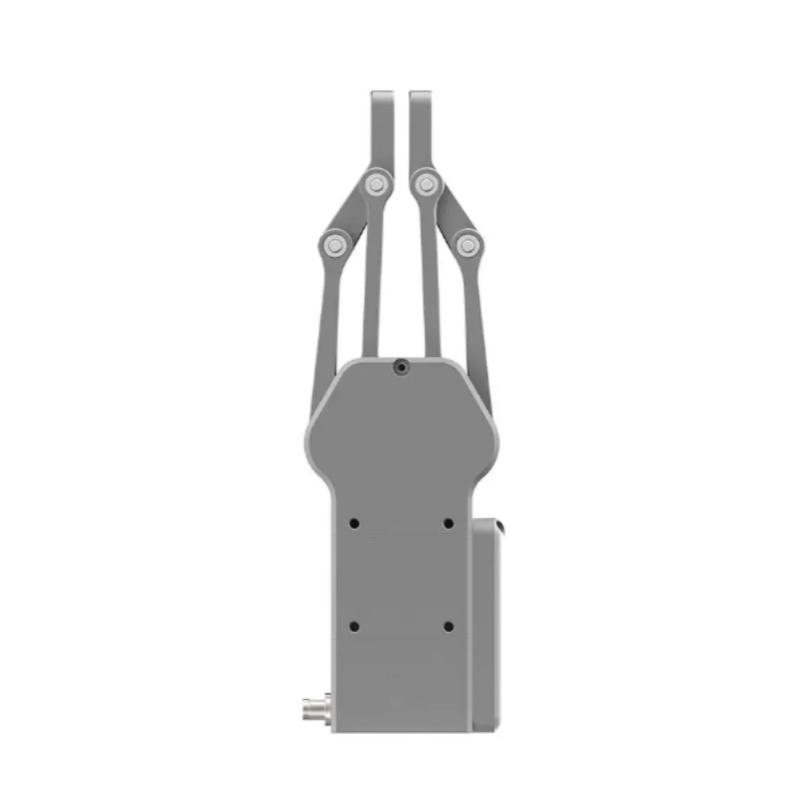

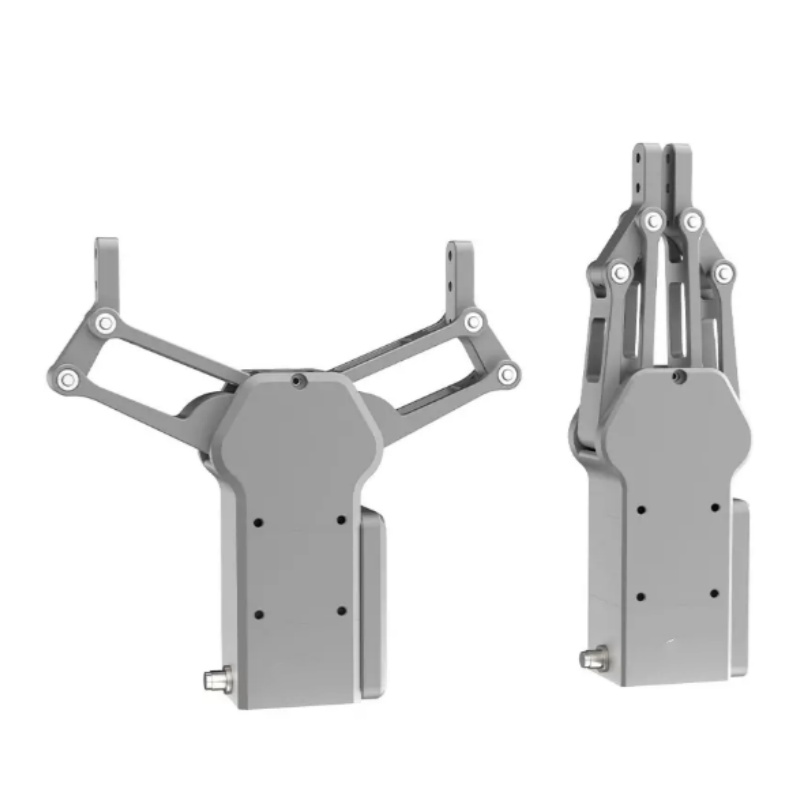

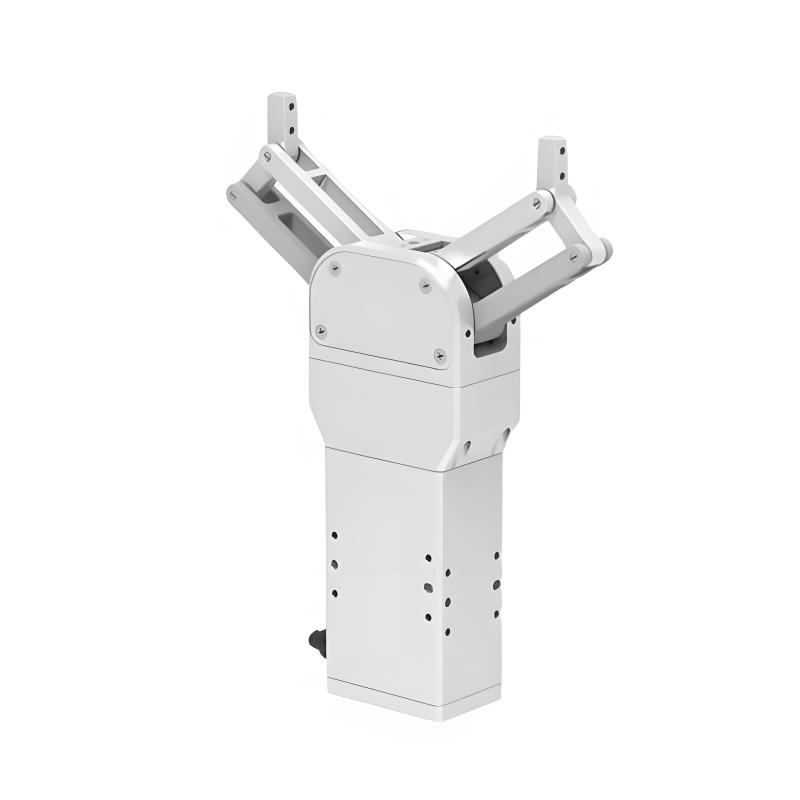

Product Display

Plug and Play, Convenient to Integrate

Electric gripper can be compatible with collabo-rative robot arm, and it has integrated servo system inside,only one gripper can be equal to compressor + Filter +Solenoid Valve + Throttle Valve + air gripper.

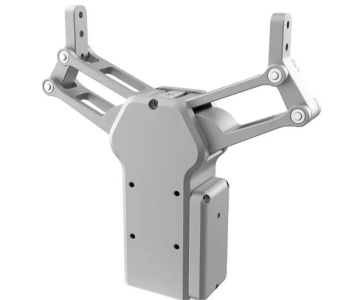

Long Stroke, Great Compatibility

The efficient stroke of electric gripper can be up to 12Omm, its closing size is 1Omm, the electric gripper can be used for semiconductor chip, 3C electronic and other precision indus-tries, etc.

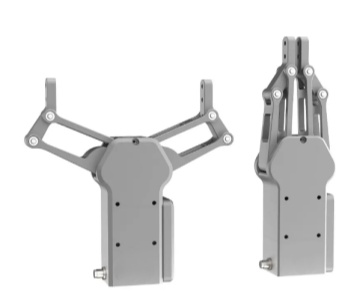

Small Size, Convenient to Integrate

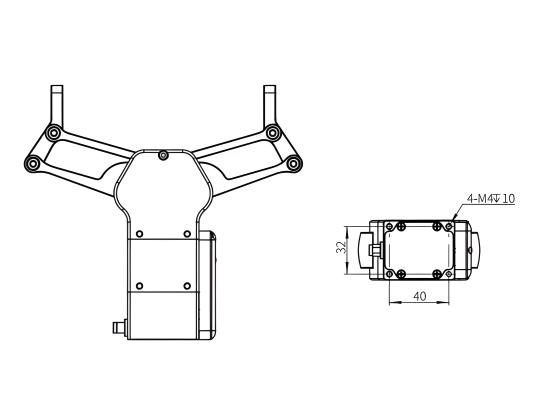

The opening size of Electric gripper is 171*187*40mm, closing size is 218*66.5*40mm, it is compact structure, support multiply installation types, it is controller inside, small area covered.

Accuracy Force Control

The electric gripper is to utilize special transmission design and drive algorithm compensation, clamping force is 40-130N adjustable, suggestion clamping weight≤1kg, and it can realize repeatability of ±0.02mm.

Adaptive Grab, Tail Changeable

The electric gripper supports adaptive clamping,it is more suitable for circular, sphericity or special-shaped object, its tail parts can be changeable at ease, customers can clamp the objects according to their requirement.

Multiply Control Modes, Easy to Operate

The electric gripper can be accuracy controlled by Modbus, its configuration is simple, to utilize the communication protocol of Digital I/O, just need one cable to connect with ON/OFF, it is compatible with PLC main control system.

Size & Interface

Application Cases

Industrial automation production line: Precisely grab gears, screws and other parts in automobile manufacturing to complete automated assembly, and improve production line efficiency with high-precision drive systems.

Logistics warehousing and sorting: Quickly grab cartons, packages and other special-shaped goods, adapt to e-commerce logistics scenarios, and achieve efficient sorting and stacking through flexible opening and closing design.

3C electronic manufacturing: On mobile phone/computer production lines, accurately clamp chips, capacitors and other tiny components to meet the precision mounting requirements of the electronics industry and ensure product assembly accuracy.

Food processing and packaging: Grab bread, boxed food, etc. The material is corrosion-resistant and easy to clean, adapts to the hygiene requirements of the food industry, and flexibly completes sorting and packaging tasks.

Medical and pharmaceutical fields: Stably grab test tubes and sample boxes in laboratories, or process drug packaging in pharmaceutical factories, to meet the cleanliness and precision operation requirements of medical scenarios with stable performance.