Product Description

316/304 Stainless Steel Casting Machinery Parts, featuring special precision design, are ideal for non-standard applications. Made from high-quality stainless steel, these parts are highly corrosion-resistant, ensuring durability and longevity even in the harshest environments. With exceptional strength and reliability, they are perfect for use in demanding industrial settings, offering superior performance in challenging conditions.

What can we do?

Provide you with one-stop stainless steel precision parts customization service

R&D and design |

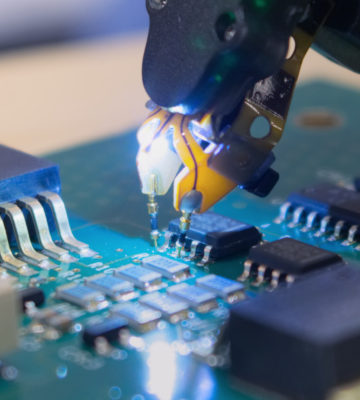

Precision casting |

CNC machining |

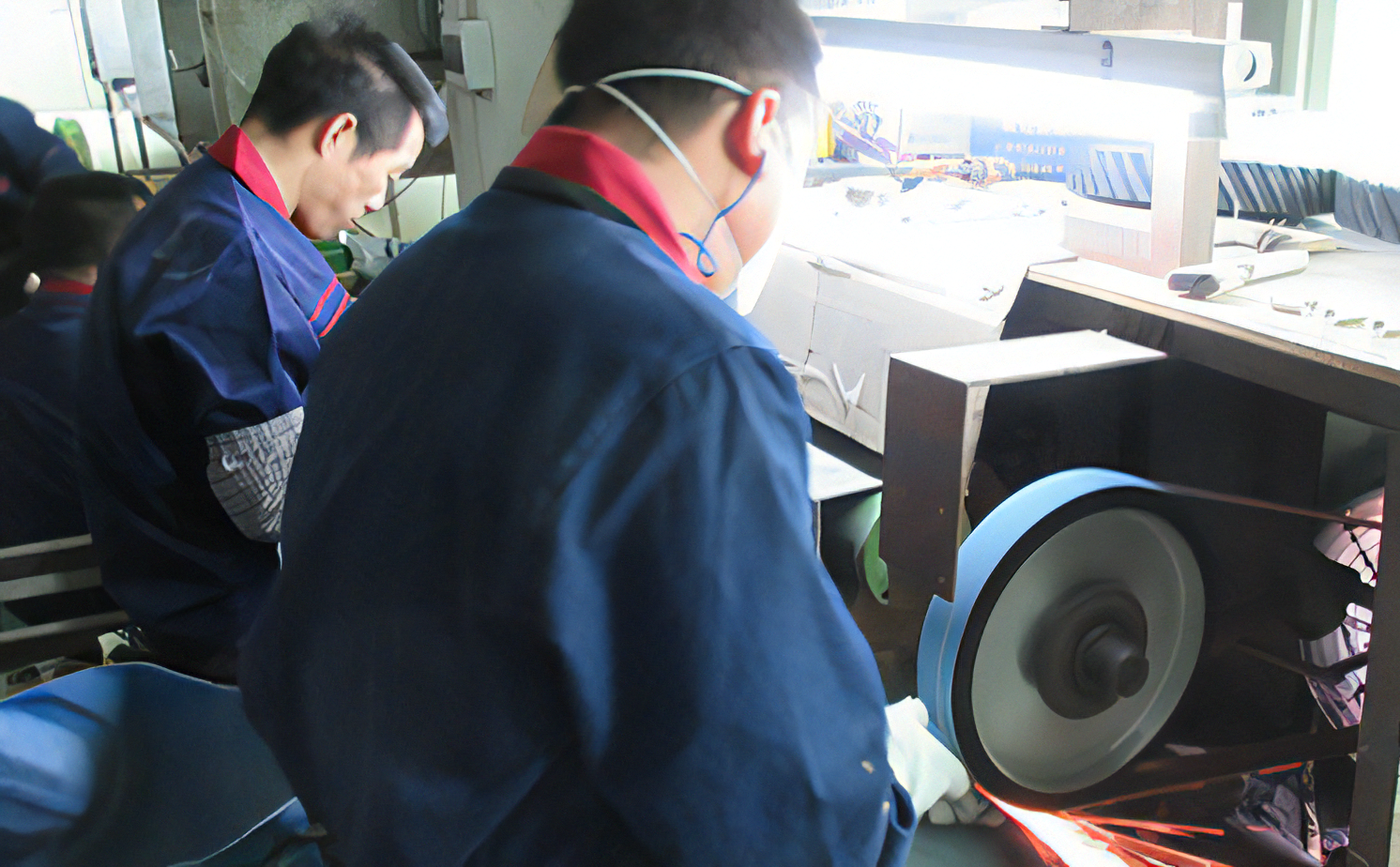

Product polishing |

Product assembly |

Foreign trade export |

Product information

Product information

| Product name | Non-standard stainless steel parts |

| Customization | Customization is available with drawings and samples |

| Product technology | Silica sol precision casting/lost wax casting/investment casting |

| Surface treatment | Pickling, polishing, sandblasting, electrolysis, electroplating, blackening, etc |

| Product processing | We have a variety of processing equipment such as CNC and machining to meet your various processing needs |

COMPANY STRENGTH

COMPANY STRENGTH

| Full silica sol casting production line |

| More than 20 Taiwan precision casting equipment |

| More than 200 polishing equipment |

| More than 70 CNC and processing equipment |

| Finished product assembly line |

| Products are exported to countries all over the world |

Application

Flexible customization, wide range of uses

Pump & Valve Industry |

Aerospace |

Navigation & shipping |

Building materials industry |

Medical industry |

Machinery industry |

Automotive industry |

Home appliance industry |

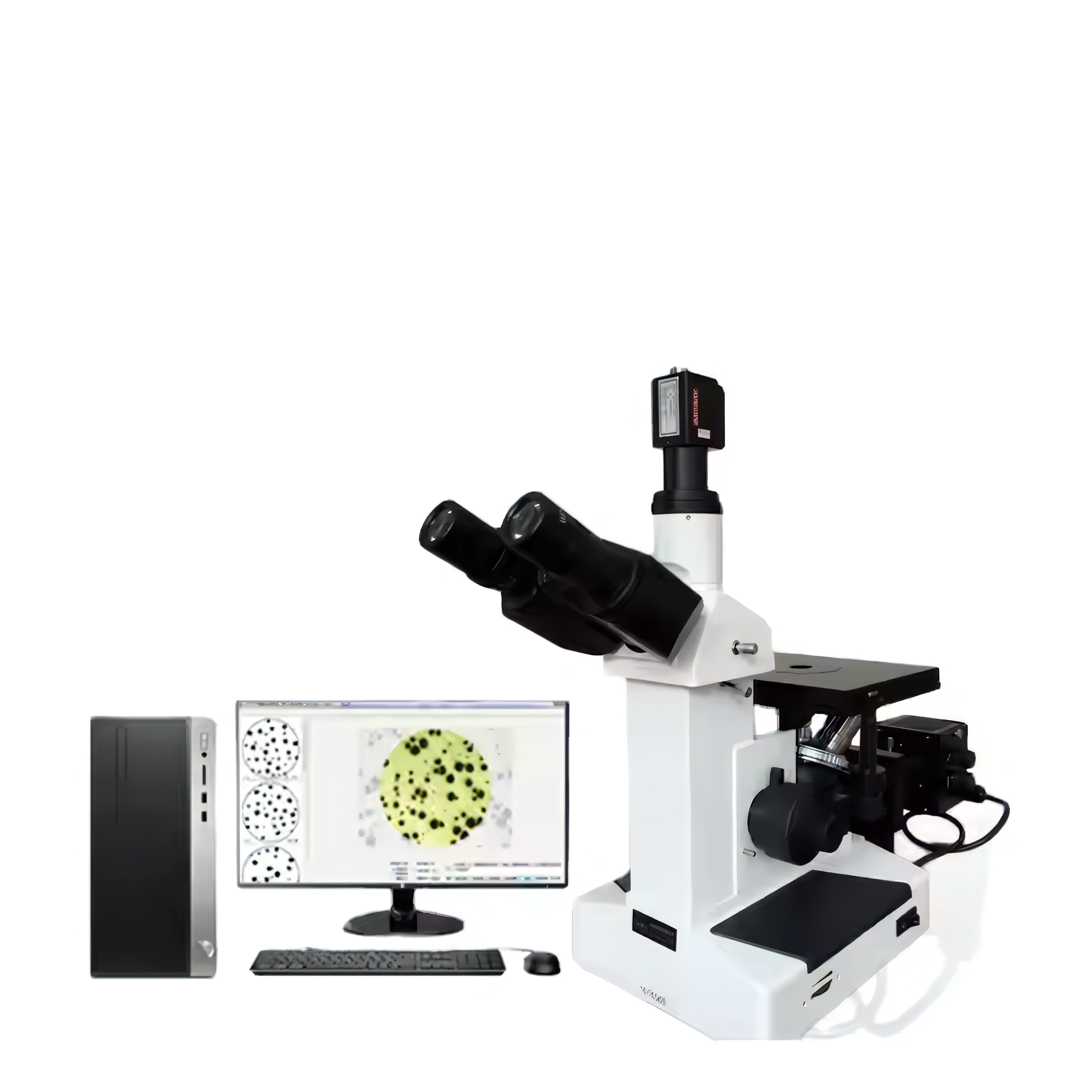

Quality Control

QUALITY CONTROL

Testing equipment display

Arnos quality control is strictly carried out in accordance with ISO standard procedures, combined with refined management to ensure product quality

|

|

|

|

|

|

|

|

Custom Process

| Propose requirements Provide drawings or samples |

| Product quotation Quote according to requirements |

| Open mold and make samples Arrange samples after paying mold fees |

| Pay deposit Pay bulk deposit after confirming samples |

| Arrange production Schedule production according to signed sample requirements |

| Pay balance Pay balance before shipment |

| Confirm receipt Logistics shipment and confirmation |

Product parameters

Types of Sand Casting | Clay Dry Sand Type |

Catalog Number | Casting 347 |

Special Casting Types | Lost Foam Casting |

Surface Treatment | Blank Surface, Brushed, Mirror Light |

Material | 304 / 316 / 2205 Stainless Steel |

Molding Process | Gravity Casting |

Purchase Notice

Purchase Notice

1、Our company specializes in non-standard customization, processing according to drawings and samples, no stock, please be advised!

2、The prices of all products in this store are not the actual prices of the products. Please consult the customer for quotation verification before placing an order. Orders placed without contact will be deemed invalid orders and will not be shipped. Please be aware of this and thank you for your cooperation.

3、If the customer does not respond to you in time, you can leave a message with your email and phone number and we will contact you later, or you can call us.

4、If it is not customized according to the customer's drawings, we will replace it for free and bear the domestic round-trip freight.

5、Quickly make samples in 3 days, and the minimum batch trial production can be 5 days, with fast delivery.

6、Customize strictly according to the dimensions on the drawings. If there are tolerance problems, we will replace it free of charge.