Product Description

This rotary electric gripper focuses on the needs of industrial automation, integrating electric drive technology and precision rotary structure, and can accurately perform grasping actions and realize multi-angle rotation operations. It has core advantages such as high positioning accuracy and stable clamping force, supports intelligent control, and seamlessly adapts to equipment such as robotic arms and automated production lines. It is widely used in small parts assembly, material handling, precision machining and other scenarios, effectively improving production efficiency, reducing manual dependence, and providing reliable actuator solutions for intelligent manufacturing upgrades.

Product parameters

Item | Value | Item | Value |

Item Number | Z-ERG-20C | Motor Type | Servo motor |

Total Stroke | 20mm | Rated Current | 1.5A |

Clamping Force | 10-35N | Maximum Current | 3A |

Recommended Grip Weight | 0.4kg | Rated Voltage | 24V ± 10% |

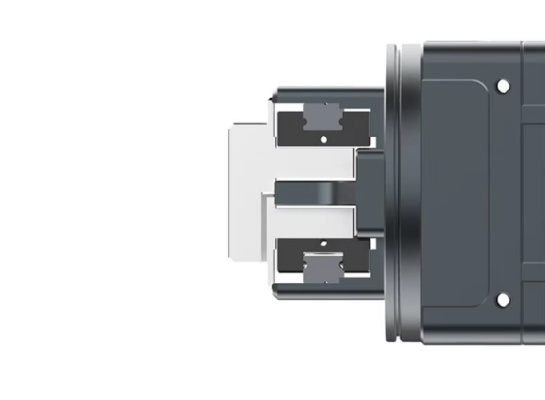

Transmission Type | Rack and Pinion + Linear Guide | Rotational Backlash | ±1° |

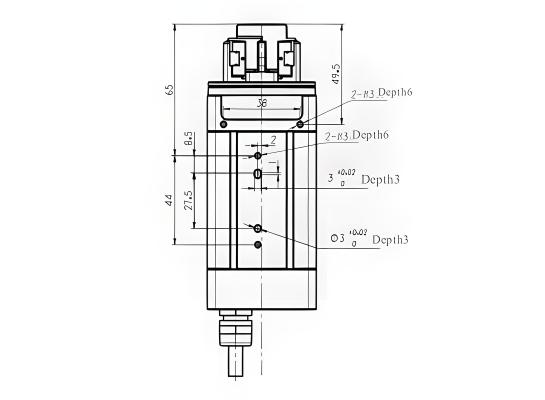

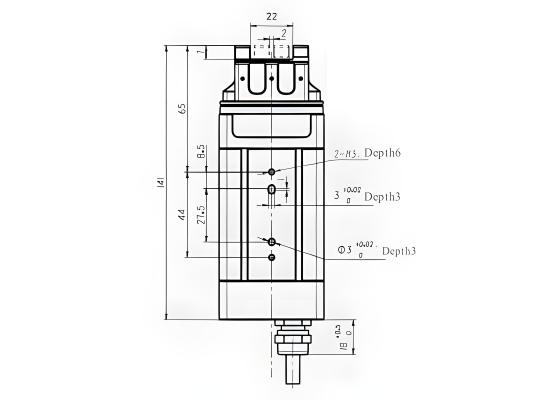

Unidirectional Stroke Time | 0.3s | Dimensions | 54*54 *142mm |

Maximum Rotational Torque | 0.3nm | Protection Rating | IP20 |

Maximum Speed | 180rpm | Operating Temperature | 5-55℃ |

Repeatability | 0.2mm | Operating Humidity | RH35-80 (frost-free) |

Rotational Distance | Infinite rotation |

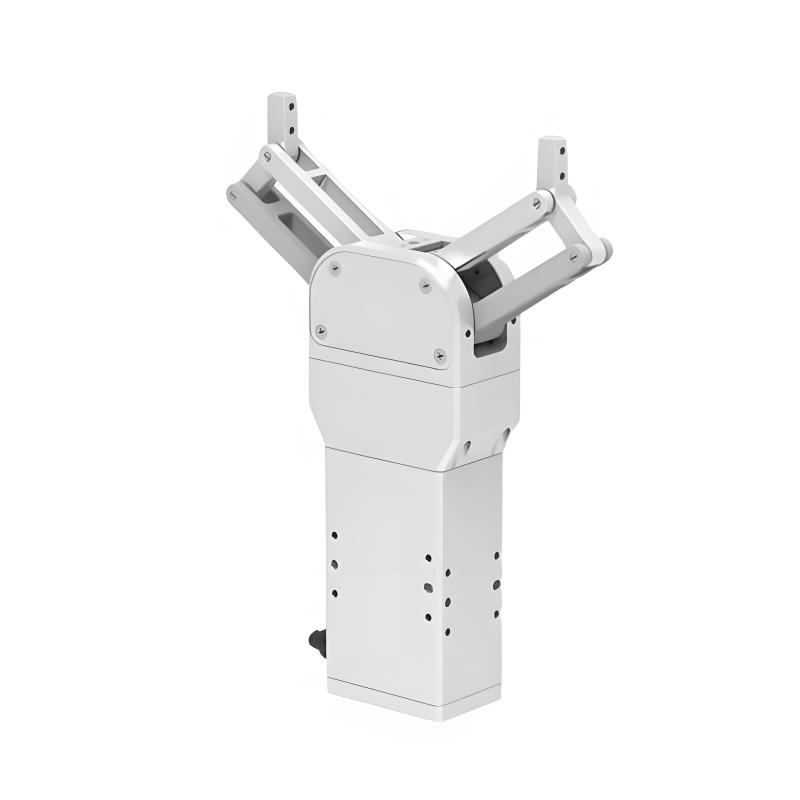

Product Display

Comprehensive functions, compact structure

This rotary electric gripper integrates a servo system, is small in size, and has excellent performance.

Controller and Driving Integrated, Soft Clamping

The time of open/close is just 0.3s,its speed, clamping force, bit can be accurately controlled by Modbus, it supports soft clamping,being able to clamp fragile objects, such as bean curd, tube and egg, etc.

Ultra-High Repeatability

The repeatability of the electric gripper is ±0.02mm, by accurate force and positioning control, the electric gripper can be more stable to complete the tasks of clamping and rotation.

Long Stroke, Wide Application Fields

Industrial electric gripper with 20mm total stroke, its clamping force can be up to 10-35N, rotation torque is 0.3N.m, it can be widely used for biomedicine, lithium battery, automative parts, 3C, food, glass products, cosmetics, machine tool processing, molded plastic, logistics and semiconductor industries, etc.

Multiple Control Mode, Easy to Operate

The electric clamping is simple configuration, to use the com-munication protocol of digital I/O, just need one cable to connect ON/OFF, to be perfect compatible with PLC main control system.

Size & Interface

Application Cases

3C electronic manufacturing: In chip mounting and precision parts assembly, the rotating electric gripper can accurately grasp tiny electronic components with its high-precision positioning capability, and complete multi-angle alignment through flexible rotation, solving the precision assembly requirements that are difficult to achieve manually, and greatly reducing the defect rate.

Automotive parts production: When handling workpieces such as gears and bearings, it relies on stable clamping force and intelligent rotation control, and cooperates with the robotic arm to efficiently complete welding, assembly and other processes. Compared with traditional grippers, it reduces repeated debugging time and improves the automation efficiency of the production line.

Packaging industry: In food and daily necessities packaging, the gripper can accurately grasp the product and adjust the posture to put it into the packaging box through rapid rotation positioning, replacing manual operation, achieving high-speed and stable automated packaging, and reducing labor costs.

Logistics sorting: When grabbing a package, with the help of the rapid rotation code scanning function, the package angle is automatically adjusted to complete information recognition, and with efficient clamping actions, the sorting efficiency is improved, manual intervention is reduced, and the warehouse logistics automation process is optimized.