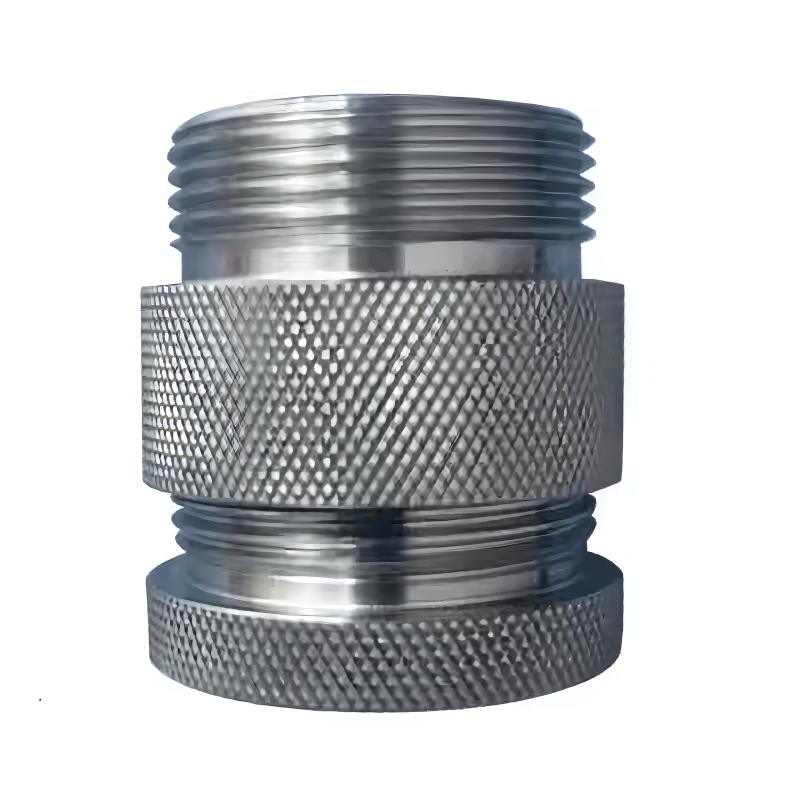

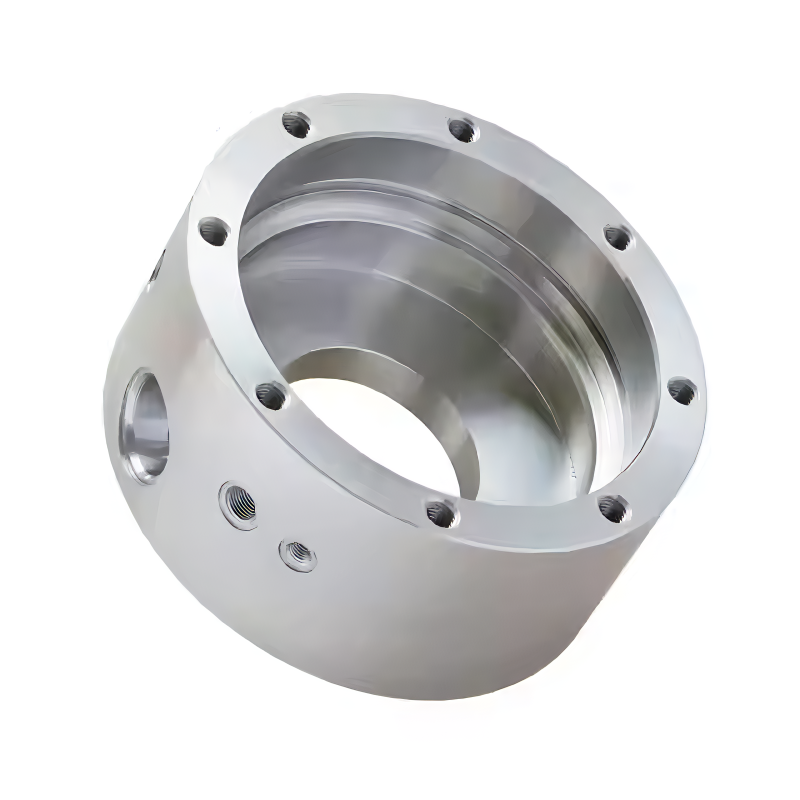

Product Description

We produce CNC parts using state-of-the-art technology, offering precise and fast service for steel, plastic, and aluminum. Our expertise allows us to deliver exceptional results in every piece, whether it's for high-volume production or custom orders. With a commitment to quality and attention to detail, we ensure that each part meets the highest standards of precision and durability.

Product parameters

item | value |

CNC Machining or Not | Cnc Machining |

Material Capabilities | Brass, Aluminum, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys, Other |

Type | Milling |

Micro Machining or Not | Micro Machining |

Model | metal CNC machining |

Brand | Reteck Model |

Tolerance | 0.005-0.01 |

Surface treatment | Anodizing, sandblasting, powder spraying, spray painting |

File formats | PRT, STP, IGS, X-T, SLDPRT, STL, OBJ |

Quality control | 100% inspection before delivery |

Production lead time | 5-7 days |

Delivery time | 3-5 days ODM high quality precision CNC machining services |

Processing | type CNC machining |

OEM/ODM | CNC machining vacuum casting rapid prototyping customization |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Tool Storage Cabinets

Sheet metal is used in the production of tool storage cabinets and equipment that need to withstand heavy usage in factories or work environments with challenging conditions, such as high dust or humidity. Sheet metal provides strength, durability, and impact resistance, making the cabinets long-lasting and capable of protecting tools from damage

Agricultural Equipment

Agricultural tools such as tractors and heavy-duty farming machinery require materials that are strong, durable, and able to handle harsh working environments, such as muddy fields or rapidly changing weather conditions. Sheet metal provides the necessary toughness and can resist wear and tear from impacts and friction

Solar Panels

Sheet metal is used for creating frames for solar panels due to its durability and ability to protect the solar panels from harsh weather conditions or corrosion from moisture. The sheet metal helps ensure that the panels are stable and extends their lifespan, making it suitable for outdoor use

Material

Aluminum Alloy

Stainless Steel

Quality Control

At Micro Mach, we prioritize quality control in every step of our CNC turning and milling processes to ensure that every part we produce meets the highest standards of precision and durability. Our advanced technology and rigorous inspection protocols allow us to maintain strict tolerances and deliver consistent, high-quality results. From the initial design phase to the final inspection, we carefully monitor each production stage to prevent defects and guarantee that all components are manufactured to the exact specifications.

Processing capability

Additional processes