Product Description

This long-stroke micro electric gripper breaks through the operating boundaries with its exquisite shape, integrates an ultra-long stroke design in a compact structure, and can easily cope with the grasping range that is difficult to cover with conventional grippers, and is perfectly adapted to automation scenarios with limited space. It is equipped with a high-precision drive system to achieve ±0.01mm repeatability accuracy, ensuring stable and non-offset grasping and placement of workpieces; it supports multiple industrial communication protocols such as EtherCAT and Modbus, and seamlessly links robots, vision systems and other equipment to build an efficient automation ecosystem. It also has preset practical functions such as adaptive clamping, drop detection, and regional signal output, and can be put into use right out of the box. It is widely used in 3C electronic assembly, new energy battery manufacturing, precision parts processing and other fields. Whether it is a tiny chip or a large-size module, it can be flexibly grasped with the advantage of a large stroke, injecting kinetic energy into the automated production line with stable performance and high compatibility, significantly improving production efficiency and operating accuracy.

Product parameters

Description item | Parameter Description | |

Model name | RM-CGBD-11-100-ITG | RM-CGBD-17-100-ITG |

Size number | 11 | 17 |

Specifications | 100 | 100 |

Stroke (mm) | 90 | 90 |

Maximum clamping force ¹ (N) | 40 | 70 |

Repeat accuracy (mm) | ±0.1 | ±0.1 |

Fastest opening/closing time (s) | 0.3/0.3 | 0.3/0.3 |

Control mode (bus) | Modbus RTU/CANopen | Modbus RTU/CANopen |

Control mode (interface) | I/O control | I/O control |

I/O interface | Input 2 points (NPN) | Input 2 points (NPN) |

Rated voltage (V) | DC24±10% | DC24±10% |

Rated current (A) | 2 | 4 |

Mass (kg) | 0.7 | 1.6 |

Usage environment | 0~40℃, 85% RH or less | 0~40℃, 85% RH or less |

Protection level | IP40 | IP40 |

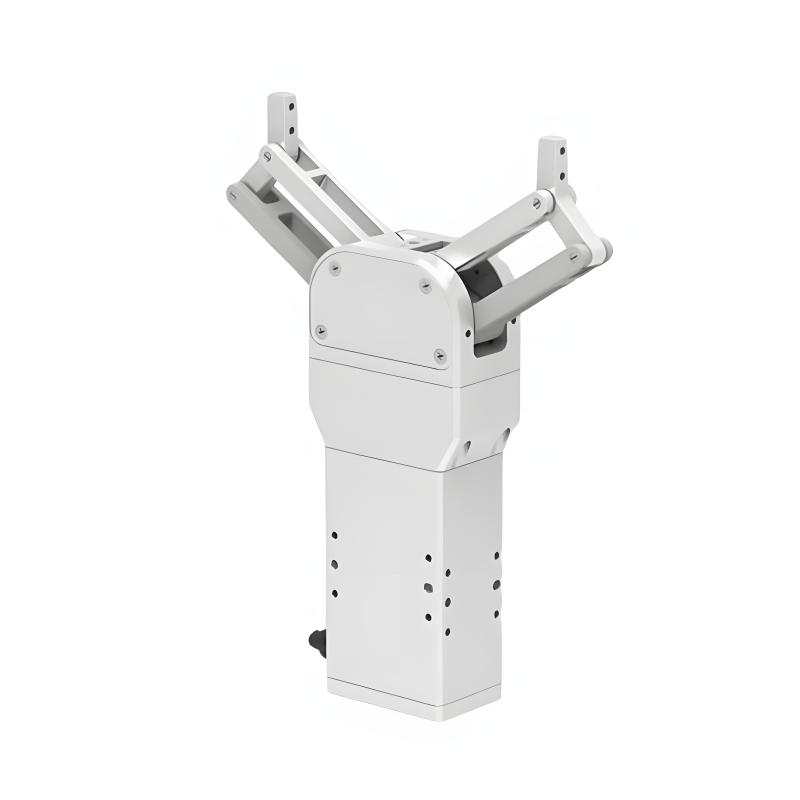

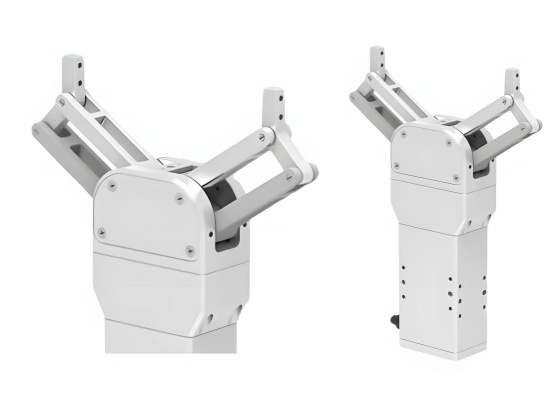

Product Display

Multi-communication compatibility

Integrated bus, I/O, pulse three-in-one control, supports EtherCAT, Modbus TCP and other industrial network standards, seamlessly connects to different industrial control systems.

Functions are ready to use

10+ practical functions are preset, including adaptive clamping/pushing, drop detection, regional signal output, etc., no complex debugging is required after unpacking, and it can be put into use quickly.

Flexible and efficient development

Provides complete SDK and API, compatible with programming languages such as C++, Python and Linux/Windows systems, to help developers secondary development and expand advanced applications.

Ecological open adaptation

Supports docking with visual systems, industrial robots, collaborative robots and other equipment, flexibly integrates into multiple automation scenarios, and improves system integration compatibility.

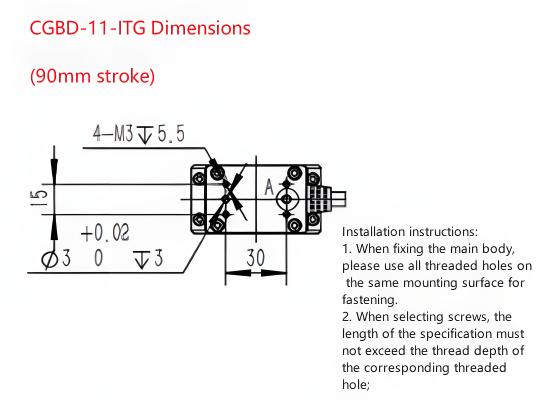

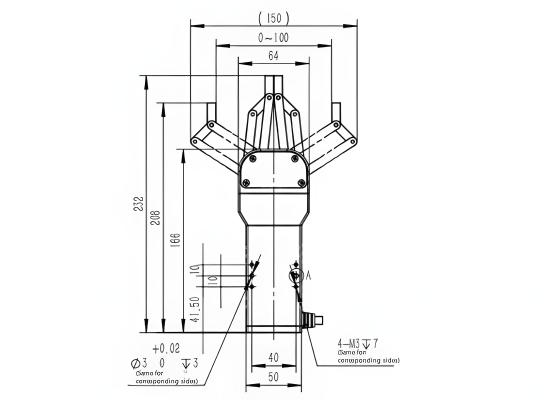

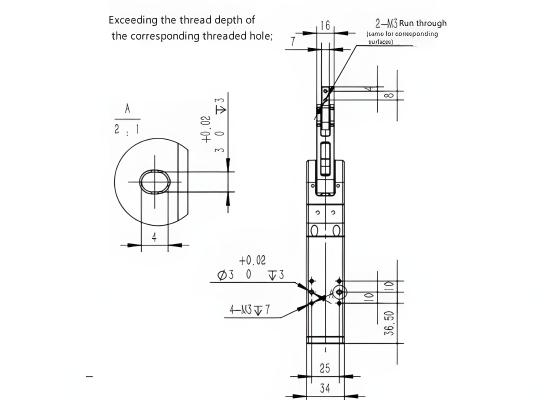

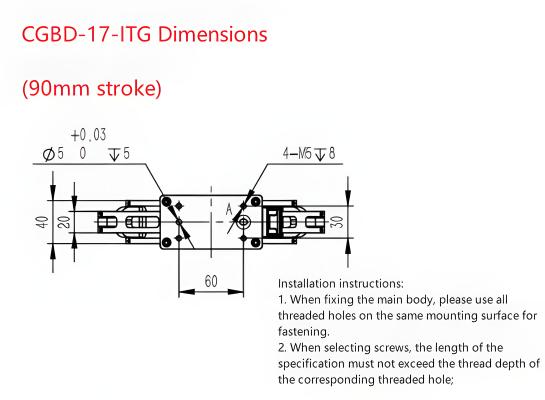

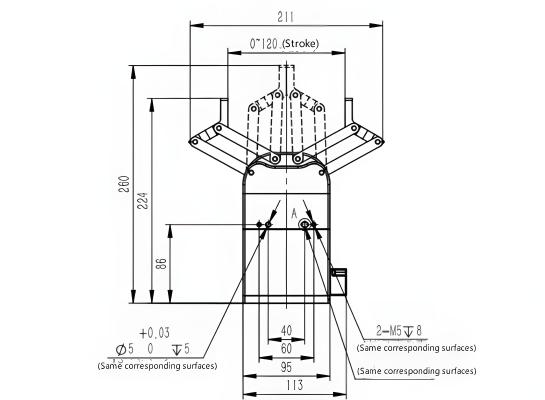

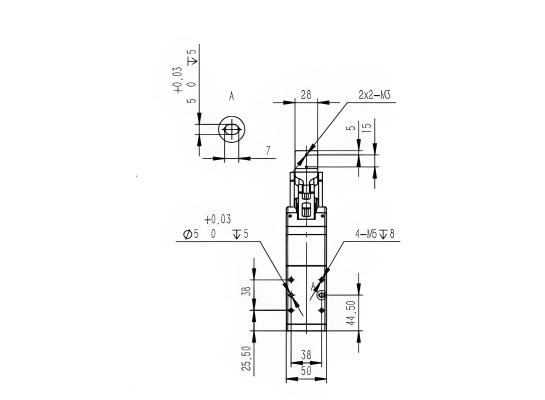

Size & Interface

Application Cases

Semiconductor wafer and chip processing:In semiconductor wafer cutting and chip mounting scenarios, the large stroke of the gripper can cover the transfer distance from the wafer tray to the cutting equipment, and the miniaturized design meets the miniaturization requirements of dust-free workshop equipment. For 5mm-150mm chips, high-precision clamping and large-stroke movement can achieve accurate loading and sorting of wafers and chips, adapting to the high cleanliness and high-precision operation requirements of the semiconductor industry.

Assembly of precision mechanical parts:When assembling precision gears of automobile engines and micro-parts of aerospace, the large stroke of the gripper can grasp parts with large diameter differences (such as 5-100mm gears), and the micro structure is adapted to precision assembly equipment. Through the preset adaptive clamping function, special-shaped parts can be grasped stably to ensure the consistency and accuracy of mechanical parts assembly.

Production of medical equipment and consumables:In the assembly of medical catheters and the production of in vitro diagnostic reagent cards, the large stroke of the gripper meets the grasping requirements of long catheters (100-400mm), and the miniaturized design is adapted to the clean space of medical equipment production lines. During the reagent card chip implantation process, high-precision positioning and stable clamping are used to prevent medical consumables from being contaminated or damaged, thereby ensuring the production quality of medical products.