Product Description

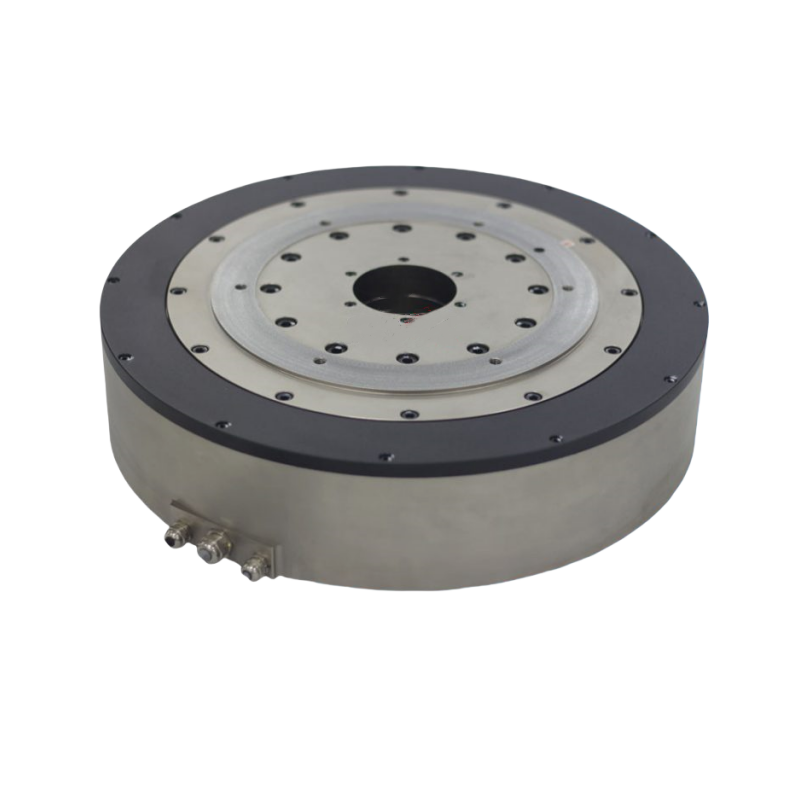

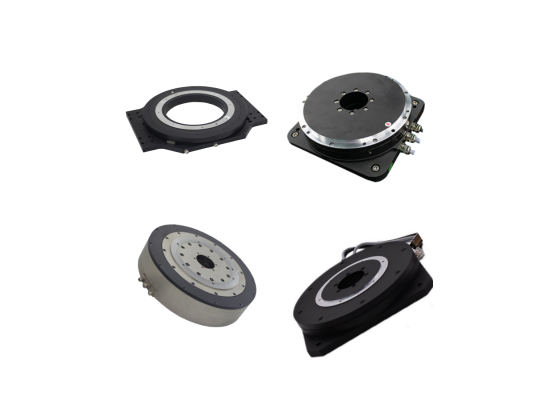

This motor offers excellent performance, high speed operation and high torque output to meet the demands of a wide range of harsh operating conditions. It has integrated Hall commutation (optional) and integrated temperature switch (optional) design, which can flexibly adapt to different use scenarios to achieve accurate regulation and safety protection. It is especially suitable for multi-station precision indexing plate control applications to ensure efficient, stable and accurate operation of equipment.

Functional Features

1. Can withstand high load

High rigidity cross roller bearing with high load capacity. In operation, it can withstand load fluctuations (no need for support structure design).

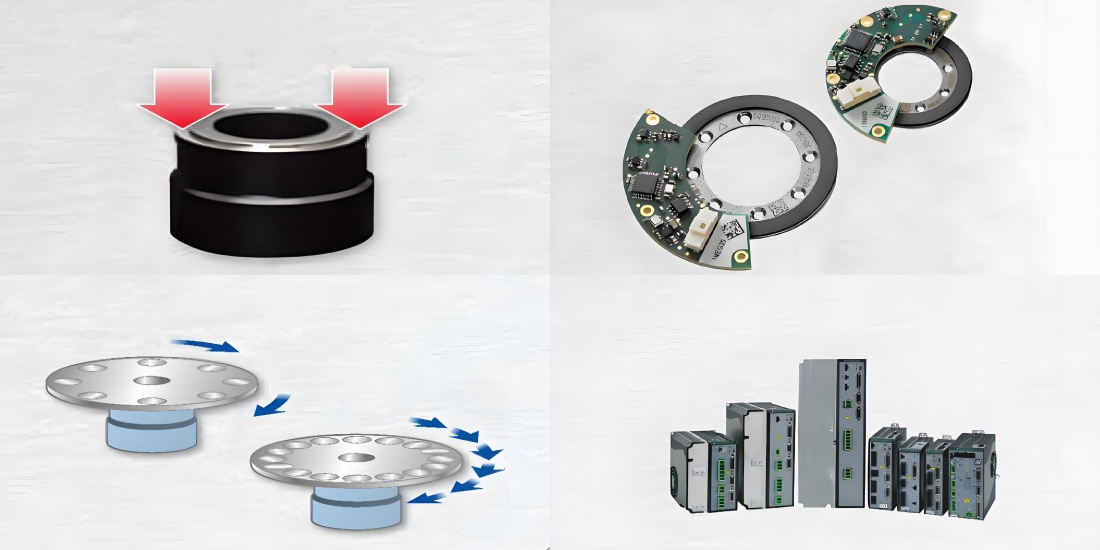

2. Absolute coder type

The built-in absolute encoder provides absolute positioning.

3. Flexible design can be done mechanically

Mechanically speaking, because the DDR has no gear structure, the station of motion can be easily changed through the program. The change of the station of the normal gear structure requires changing the gear ratio.

4. High-performance drives

The drive improves motor control and maneuverability. It has a self-tuning function and can automatically match the moment of inertia and parameters. It can be used to realize the compatibility of field network.

Application

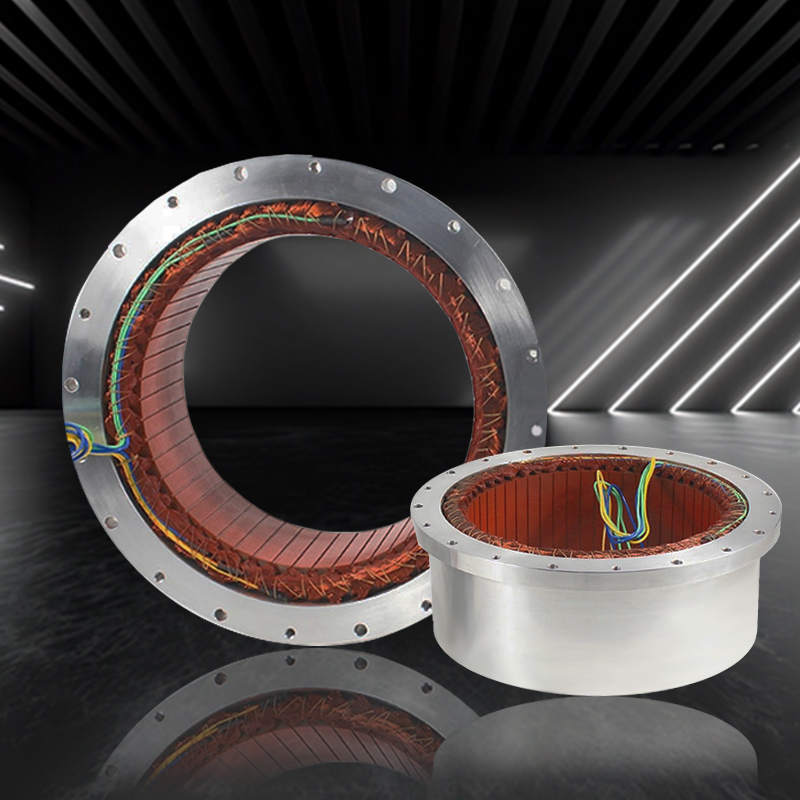

Frameless torque motor as an advanced special motor, the structure only retains the stator and rotor, abandoning the traditional shaft, bearing, housing and other components, with compact, flexible characteristics, become the ideal power source for many industrial equipment machinery. In the semiconductor process, from the photolithography and etching of chip manufacturing to wafer detection, frameless torque motors accurately control equipment movement by relying on the advantages of high torque density, low speed and large torque output to ensure high precision and high yield of chip processing. In the field of liquid crystal manufacturing, whether it is the handling of the glass substrate, the liquid crystal drip, or the module assembly, the frameless torque motor has the characteristics of fast response speed and high positioning accuracy, helping the equipment to achieve high-speed and stable operation and ensuring the high-quality production of the liquid crystal panel.

Product parameters

Main parameters | Unit | RDE-112065-W1-FA | RDE-112095-W1-FA | RDE-140080-W1-FA | RDE-140050-W1-FA | RED-170050-W1-FA | RDE-170095-WA-FA | RDE-170125-WA-FA | RDE-170155-WA-FA | RDE-224042-W1-FA |

Continuous torque | N.m | 3 | 8.5 | 10.5 | 6 | 4.5 | 23.8 | 41.8 | 59.5 | 14.1 |

Continuous current | A rms | 2.5 | 2.5 | 2.5 | 2.5 | 1.4 | 2.5 | 2.5 | 2.5 | 2.2 |

Maximum torque | N.m | 9 | 26 | 28 | 16 | 14 | 71 | 125 | 179 | 42.2 |

Maximum current | Arms | 7.5 | 7.5 | 7 | 7 | 4.2 | 7.5 | 7.5 | 7.5 | 6.6 |

Torque constant | Nm/Arms | 1.2 | 3.4 | 4.2 | 2.4 | 3.4 | 9.5 | 16.7 | 23.8 | 6.4 |

Resistance (ptp) | Ohms(25° C) | 2.2 | 4.6 | 6.6 | 4.5 | 6 | 2.52 | 3.96 | 5.22 | 8.4 |

Inductance (ptp) | mH(25° C) | L8 | 4.2 | 5.7 | 6.6 | 7.6 | 5.4 | 32 | 10 | 15.5 |

Number of poles | / | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 40 |

Back EMF constant (ptp) | Vrims/rad/s | 1 | 2.8 | 3.4 | 2 | 2.8 | 7.8 | 13.6 | 19.4 | 5.2 |

Maximum rated power consumption | W(25° C) | 26.3 | 54.9 | 78.8 | 53.7 | 22.5 | 30.1 | 47.3 | 62.3 | 77.6 |

Motor constant | Nm/ √ W | 0.6 | 1.1 | 1.2 | 0.8 | 0.9 | 4.3 | 6.1 | 7.5 | 2.6 |

Moment of inertia | Kg.m² | 0.0026 | 0.0038 | 0.0076 | 0.0045 | 0.0068 | 0.018 | 0.028 | 0.037 | 0.012 |

Motor weight | Kg | 2.7 | 4.5 | 5.6 | 3.4 | 3.9 | 9.5 | 13.5 | 17.6 | 5.5 |

Maximum speed | rpm | 350 | 250 | 350 | 600 | 450 | 190 | 150 | 120 | 380 |

Positioning accuracy | Arc sec | 士 20 | ±20 | ±20 | ±20 | ±20 | ±20 | ±20 | ±20 | ±20 |

Repeat accuracy | Arc Sec | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 |

Resolution | sin/cos | 8192 | 8192 | 8192 | 8192 | 11740 | 11740 | 11740 | 11740 | 11740 |

Maximum axial load | N | 2500 | 2500 | 2500 | 2500 | 4000 | 15000 | 15000 | 15000 | 8000 |

Maximum radial load | N.m | 20 | 20 | 20 | 20 | 40 | 150 | 150 | 150 | 80 |

Axial runout | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

Radial runout | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

Motor height | mm | 65 | 95 | 80 | 50 | 50 | 95 | 125 | 155 | 42 |

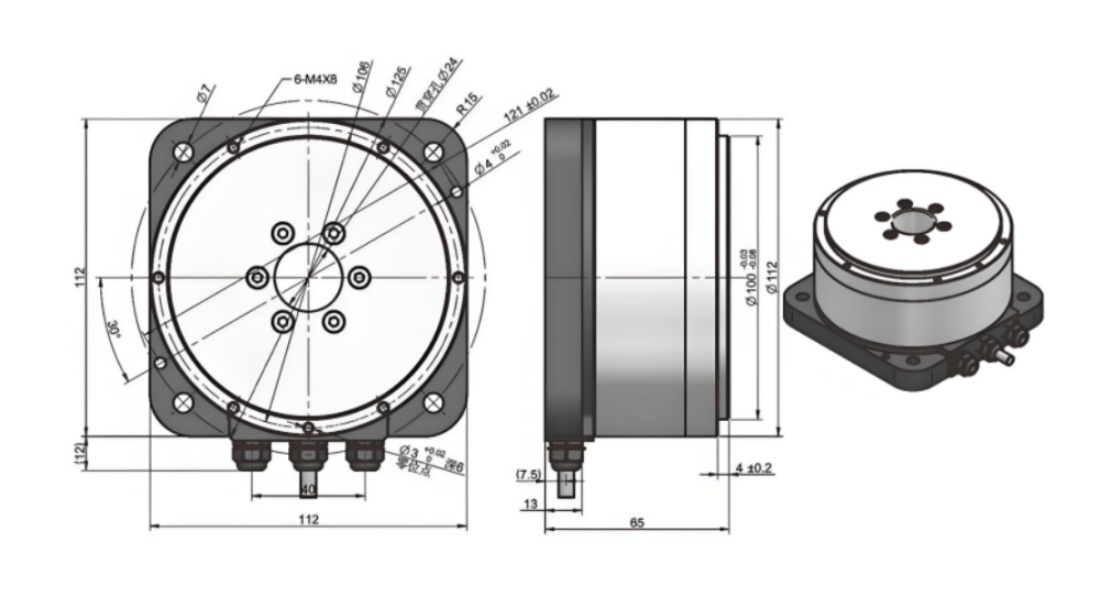

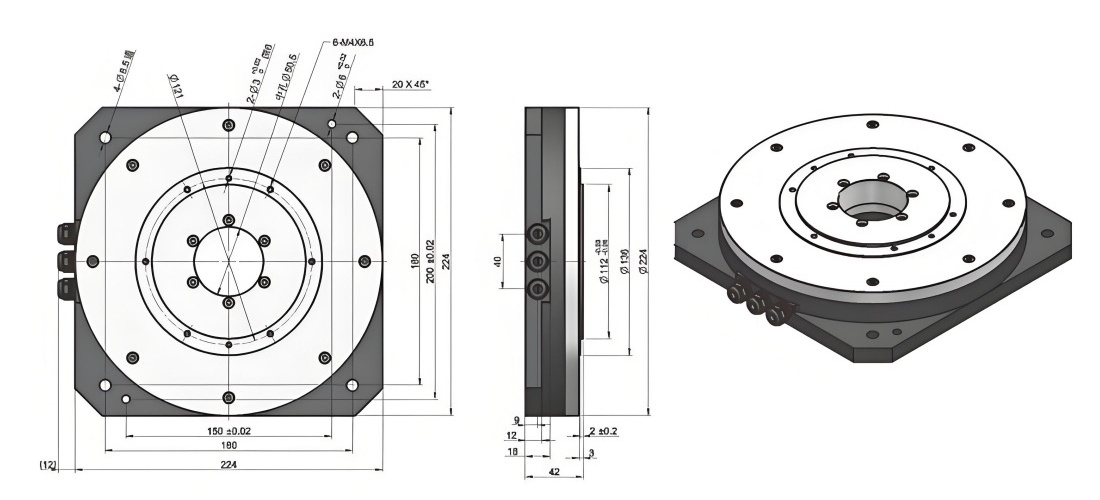

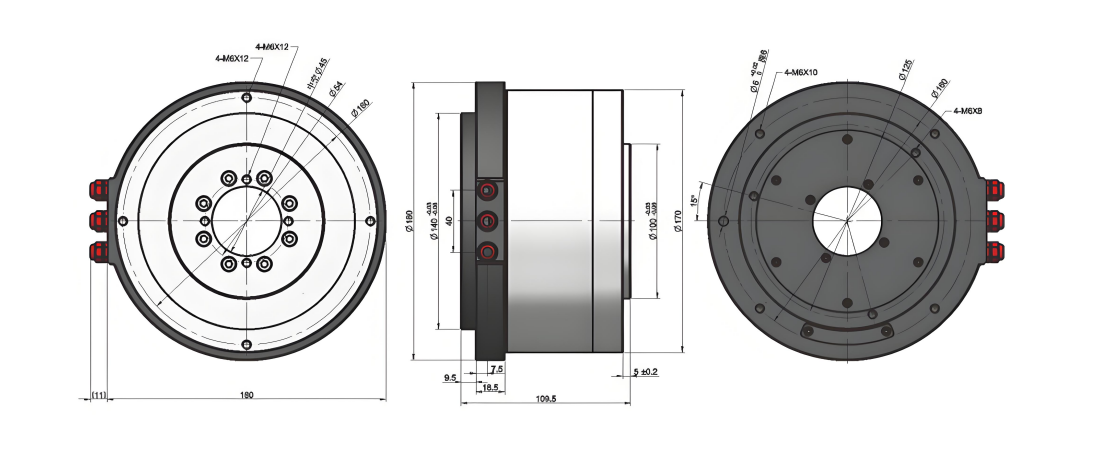

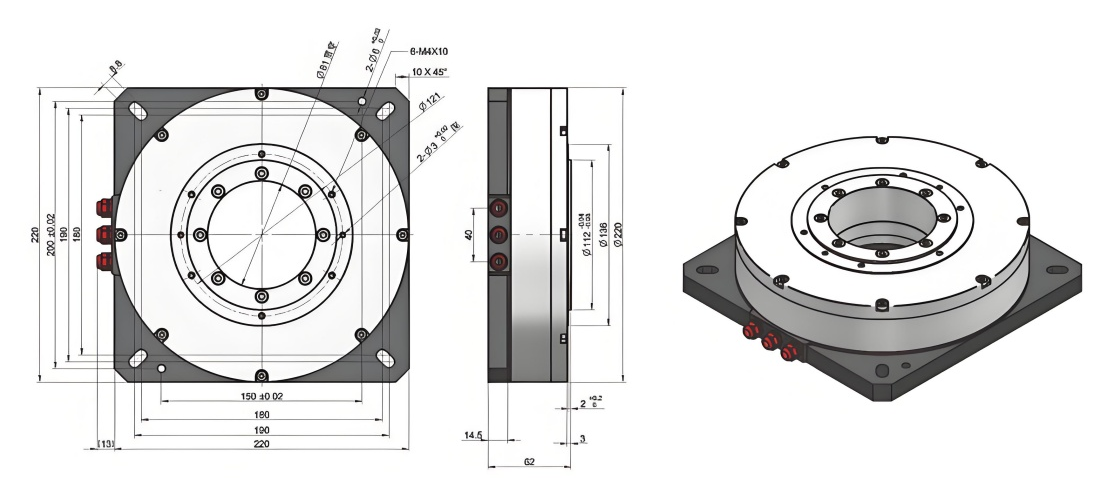

RDE-112

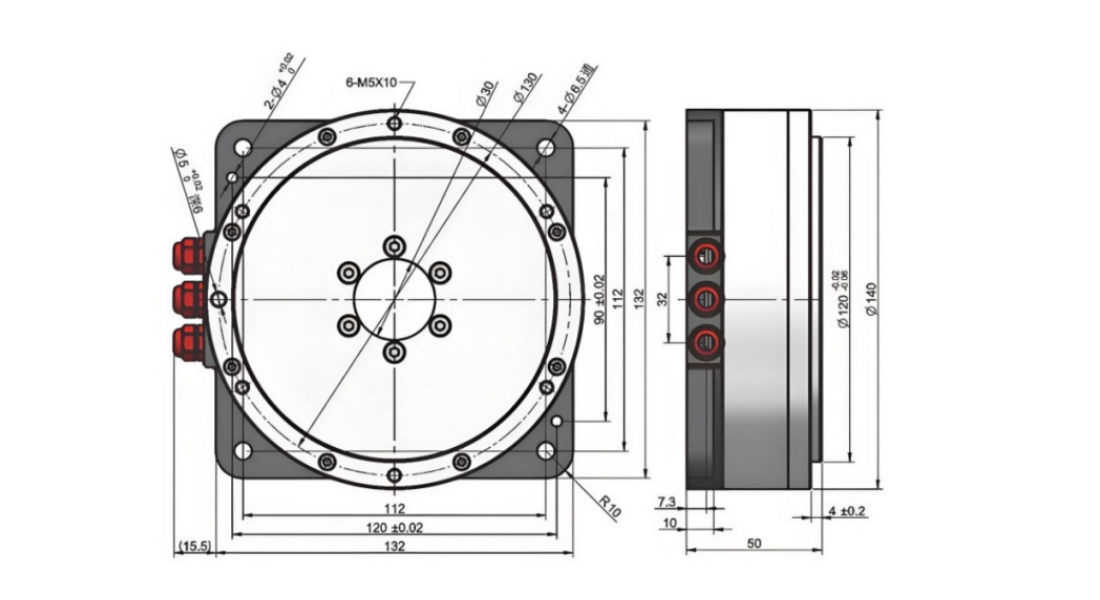

RDE-140

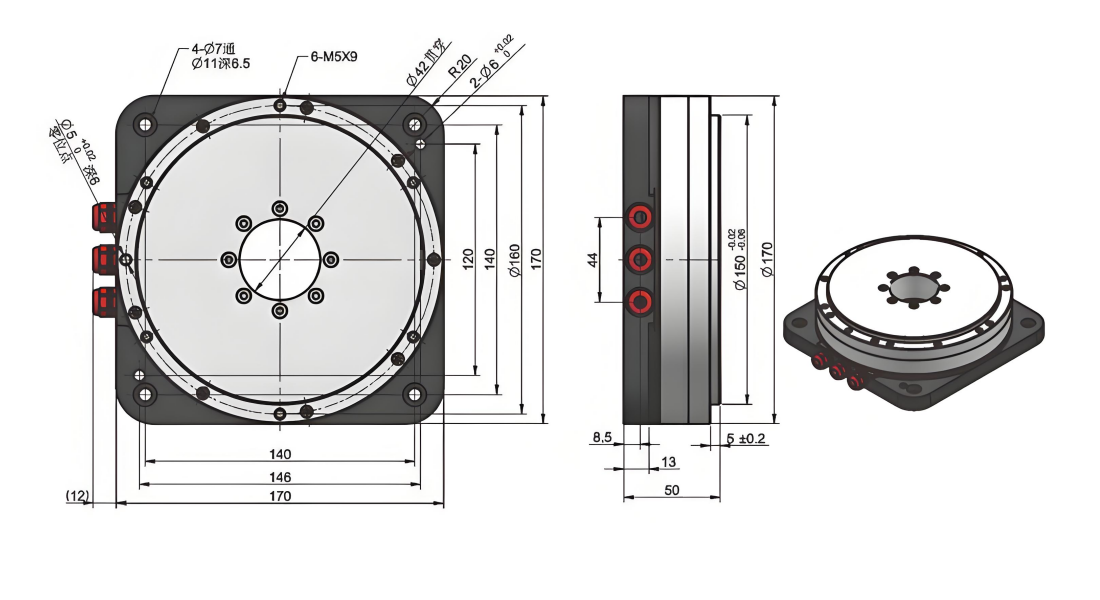

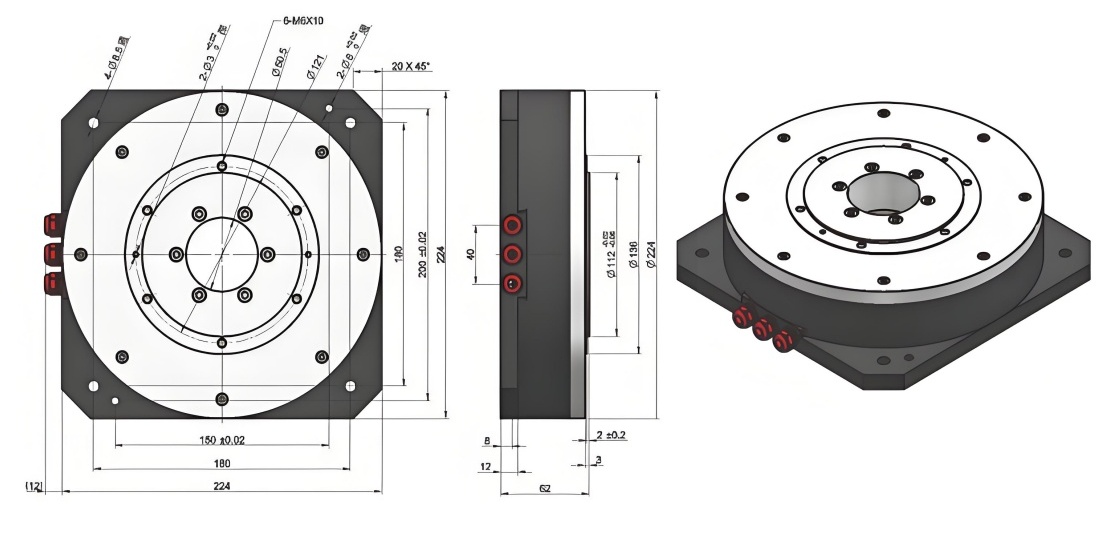

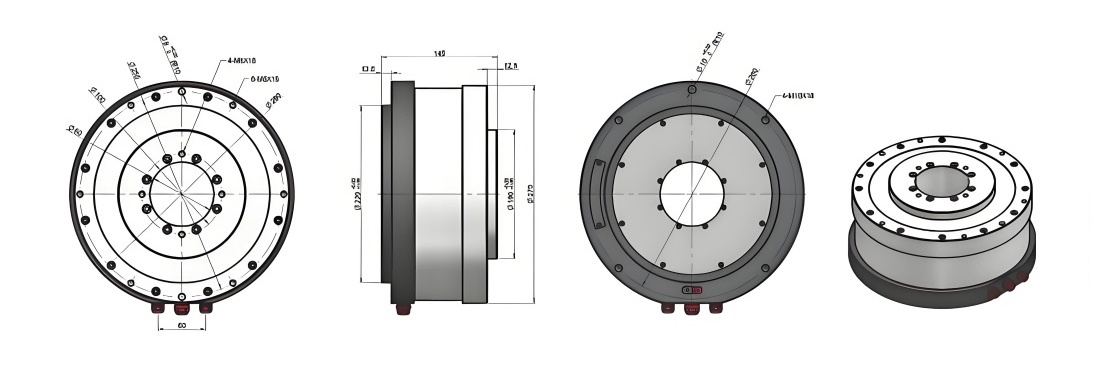

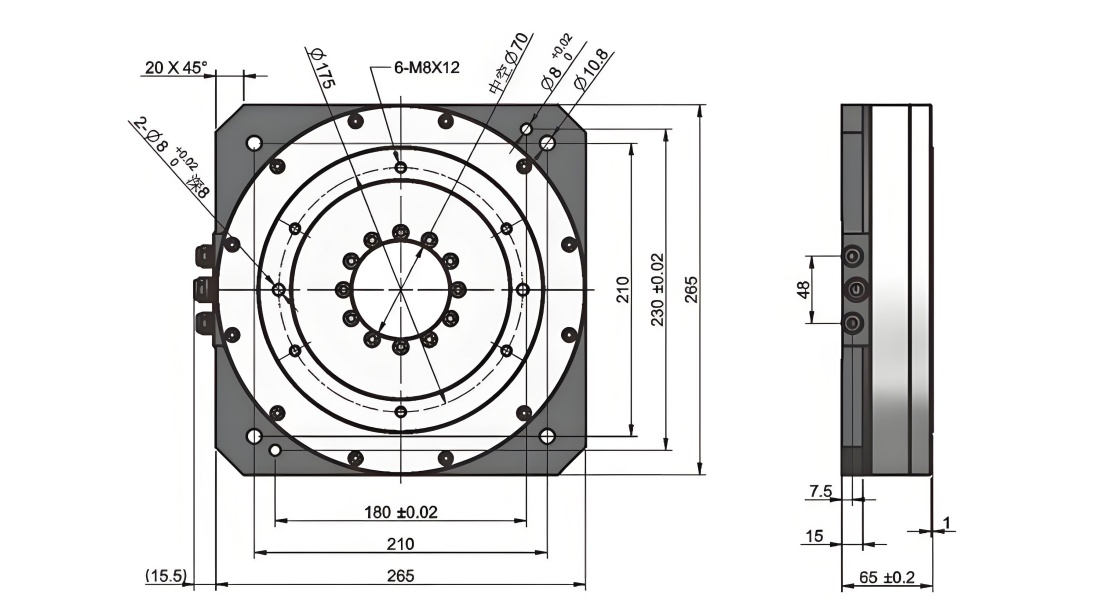

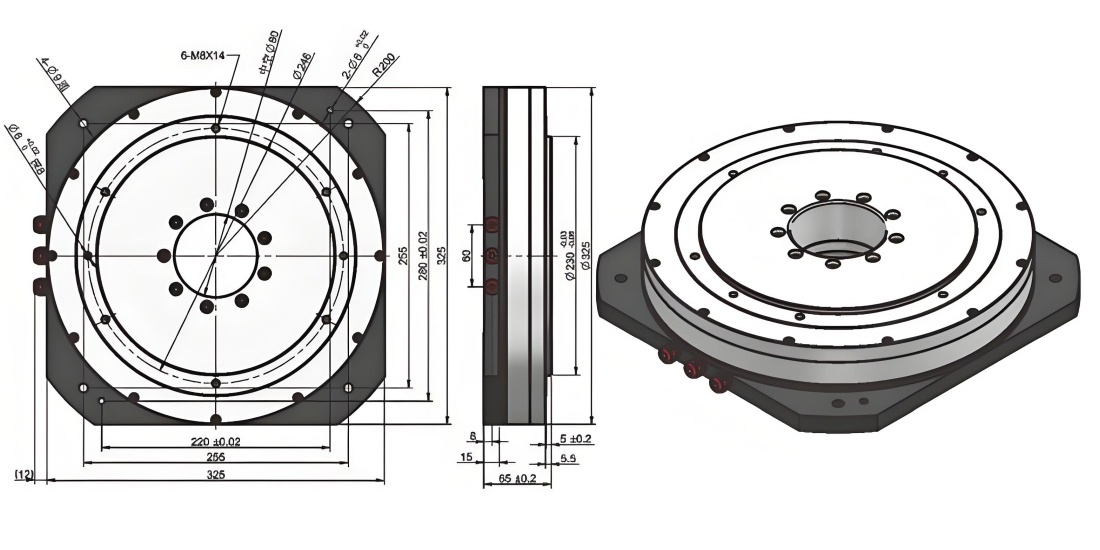

RDE-170050-W1-FA

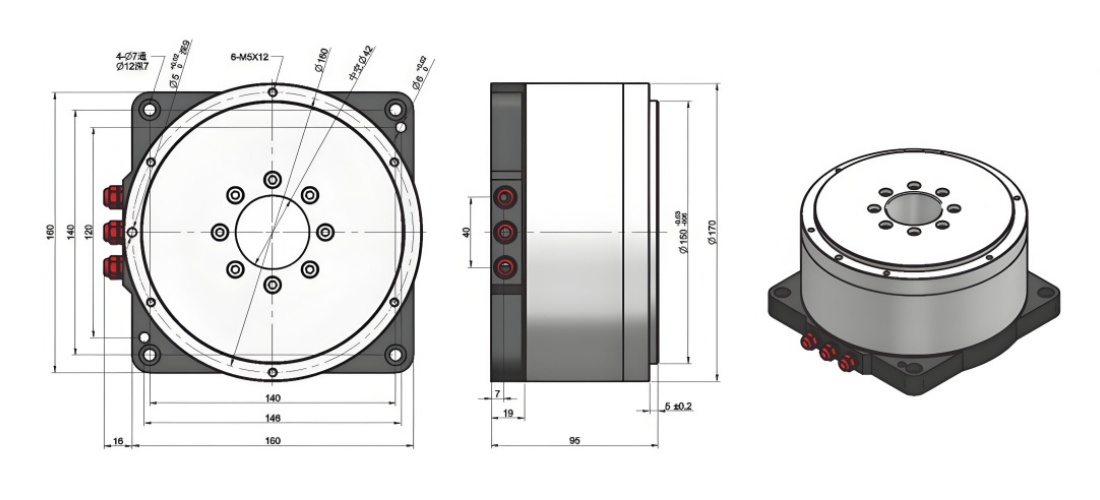

RDE-170095/170125/170155-WA-FA

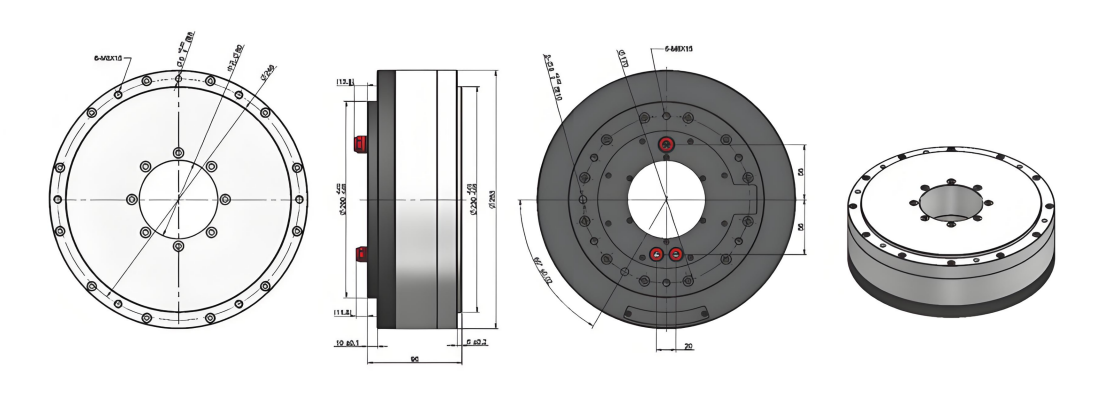

RDE-224042-W1-FA

Main parameters | Unit | RDE-224062-W1-FA | RDE-263095-W2-FA | RDE-263113-W2-FA | RDE-263138-W2-FA | RDE-263188-W2-FA | RDE-170110-W1-FA | RDE-170130-W1-FA | RDE-280145-W1-FA | RDE-280170-W1-FA | RDE-280231-W1-FA |

Continuous torque | N.m | 35 | 45 | 95 | 150 | 250 | 23.8 | 41.8 | 95 | 95 | 250 |

Continuous current | A rms | 2.2 | 7.1 | 7.1 | 7.1 | 7.1 | 2.5 | 2.5 | 7.1 | 7.1 | 7.1 |

Maximum torque | N.m | 105 | 135 | 190 | 300 | 500 | 71 | 125 | 190 | 190 | 500 |

Maximum current | Arms | 6.6 | 21.3 | 14.2 | 14.2 | 14.2 | 7.5 | 7.5 | 14.2 | 14.2 | 14.2 |

Torque constant | Nm/Arms | 15.7 | 6.3 | 13.4 | 21.9 | 35.2 | 9.5 | 16.7 | 13.4 | 13.4 | 35.2 |

Resistance (ptp) | Ohms(25° C) | 13.2 | 2.3 | 3.4 | 4.2 | 6.7 | 2.52 | 3.96 | 3.4 | 3.4 | 6.7 |

Inductance (ptp) | mH(25° C) | 36.5 | 5 | 10.8 | 13.9 | 22.8 | 5.4 | 32 | 10.8 | 10.8 | 22.8 |

Number of poles | / | 40 | 40 | 40 | 40 | 40 | 30 | 30 | 40 | 40 | 40 |

Back EMF constant (ptp) | Vrims/rad/s | 12.8 | 5.2 | 10.9 | 17.9 | 28.7 | 7.8 | 13.6 | 10.9 | 10.9 | 28.7 |

Maximum rated power consumption | W(25° C) | 122 | 221.4 | 327.3 | 404.3 | 644.9 | 30.1 | 47.3 | 327.3 | 327.3 | 644.9 |

Motor constant | Nm/ √ W | 5.6 | 7.9 | 3 | 7.9 | 7.9 | 4.3 | 6.1 | 3 | 3 | 7.9 |

Moment of inertia | Kg.m² | 0.03 | 0.076 | 0.13 | 0.15 | 0.21 | 0.018 | 0.028 | 0.13 | 0.15 | 0.27 |

Motor weight | Kg | 9.2 | 18.5 | 23.7 | 35 | 48 | 9.5 | 13.5 | 27.3 | 31.5 | 56.6 |

Maximum speed | rpm | 200 | 200 | 150 | 120 | 100 | 190 | 150 | 150 | 150 | 100 |

Positioning accuracy | Arc sec | ±20 | ±20 | ±20 | ±20 | ±20 | ±20 | ±30 | ±20 | ±20 | ±20 |

Repeat accuracy | Arc Sec | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±2.5 | ±1.5 | ±1.5 | ±1.5 |

Resolution | sin/cos | 16384 | 16384 | 16384 | 16384 | 16384 | 11740 | 11740 | 16384 | 16384 | 16384 |

Maximum axial load | N | 10000 | 40000 | 40000 | 40000 | 40000 | 15000 | 15000 | 40000 | 40000 | 40000 |

Maximum radial load | N.m | 100 | 400 | 400 | 400 | 400 | 150 | 150 | 400 | 400 | 400 |

Axial runout | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

Radial runout | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

Motor height | mm | 62 | 95 | 113 | 138 | 188 | 110 | 130 | 145 | 170 | 231 |

RDE-224062-W1-FA

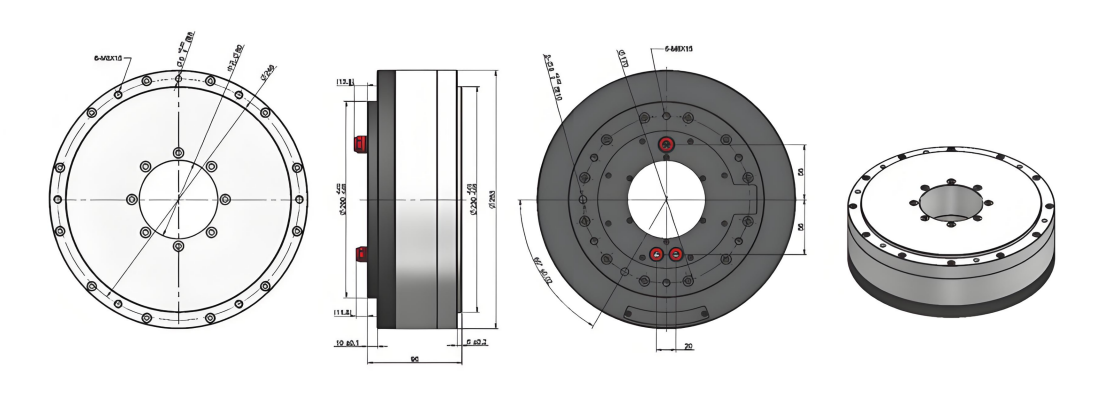

RDE-263095/263113-W2-FA

RDE-263138/263188-W2-FA

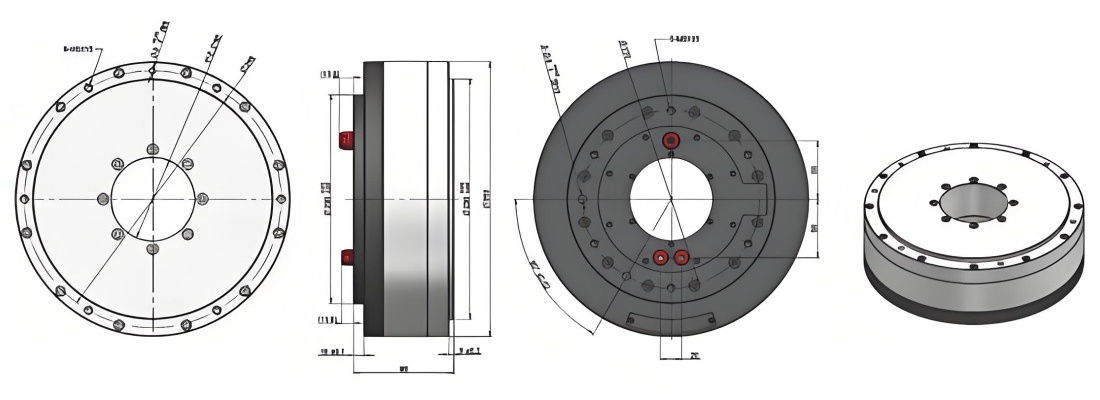

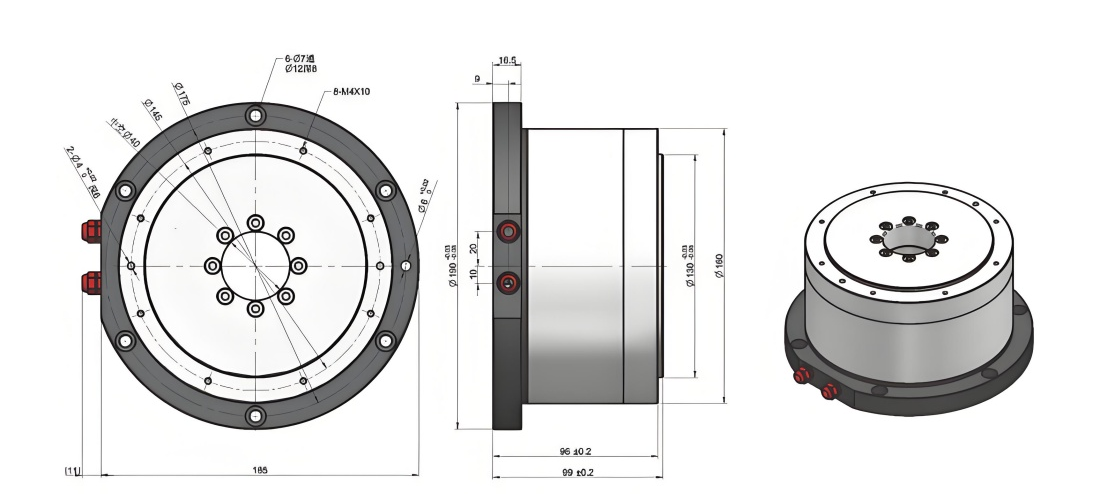

RDE-170110/170130-W1-FA

RDE-280145/280170/280231-W1-FA

Main parameters | Unit | RDE-263095-W1-FA | RDE-263112-W1-FA | RDE-263138-W1-FA | RDE-190100-WA-FA | RDE-220062-W1-FA | RDE-263065-W1-FA | RDE-325065-W1-FA | |

Continuous torque | N.m | 45 | 95 | 150 | 20 | 10.2 | 45 | 30 | |

Continuous current | A rms | 7.1 | 7.1 | 7.1 | 3 | 3 | 7.1 | 1.1 | |

Maximum torque | N.m | 135 | 190 | 300 | 60 | 30.6 | 135 | 90 | |

Maximum current | Arms | 21.3 | 14.2 | 14.2 | 9 | 9 | 21.3 | 3.4 | |

Torque constant | Nm/Arms | 6.3 | 13.4 | 21.9 | 6.7 | 3.4 | 6.3 | 27.3 | |

Resistance (ptp) | Ohms(25° C) | 2.3 | 3.4 | 4.2 | 9.4 | 13.6 | 1.7 | 13.6 | |

Inductance (ptp) | mH(25° C) | 5 | 10.8 | 13.9 | 17.9 | 7.8 | 5 | 42.4 | |

Number of poles | / | 40 | 40 | 40 | 30 | 40 | 40 | 50 | |

Back EMF constant (ptp) | Vrims/rad/s | 5.2 | 10.9 | 17.9 | 5.5 | 2.8 | 5.2 | 22.3 | |

Maximum rated power consumption | W(25° C) | 221.4 | 327.3 | 404.3 | 161.5 | 233.7 | 163.6 | 43 | |

Motor constant | Nm/ √ W | 7.9 | 3 | 7.9 | 1.6 | 5.6 | 7.9 | 4.6 | |

Moment of inertia | Kg.m² | 0.076 | 0.13 | 0.15 | 0.018 | 0.032 | 0.06 | 0.12 | |

Motor weight | Kg | 18.5 | 23.7 | 35 | 9.5 | 8.9 | 12.8 | 15.5 | |

Maximum speed | rpm | 200 | 150 | 120 | 200 | 320 | 200 | 120 | |

Positioning accuracy | Arc sec | ±20 | ±20 | ±20 | -20 | ±20 | ±20 | ±20 | |

Repeat accuracy | Arc Sec | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | ±1.5 | |

Resolution | sin/cos | 16384 | 16384 | 16384 | 11740 | 16384 | 16384 | 31488 | |

Maximum axial load | N | 40000 | 40000 | 40000 | 6000 | 5000 | 5000 | 50000 | |

Maximum radial load | N.m | 400 | 400 | 400 | 60 | 100 | 100 | 300 | |

Axial runout | mm | 0.005 | 0.005 | 0.005 | 0.005/0.002 | 0.005 | 0.002 | 0.008 | |

Radial runout | mm | 0.005 | 0.005 | 0.005 | 0.005/0.002 | 0.005 | 0.002 | 0.008 | |

Motor height | mm | 95 | 112 | 138 | 100 | 62 | 65 | 65 |

RDE-263095/263112/263138-W1-FA

RDE-190100-W1-FA

RDE-220062-W1-FA

RDE-263065-W1-FA

RDE-325065-W1-FA

Service

We provide you with a full range of frameless external rotor motor products and services. Starting from the pre-sale, the professional team provides accurate selection suggestions and detailed product quotations according to your use scenario and power needs. In the sale stage, we strictly control the production process, use advanced equipment to ensure product quality, and provide customized services to meet your special needs. When the product is delivered, it is equipped with detailed installation and debugging guidelines to ensure smooth installation and stable operation of the motor. After-sales to provide long-term technical support, rapid response to fault maintenance, regular visits to collect opinions, and constantly optimize the service. Let you use frameless external rotor motor no worries.

After-sale guarantee

We provide comprehensive after-sales service for frameless external rotor motors. During the product warranty period, if the performance failure is caused by non-human reasons, free repair or replacement of parts. With a professional after-sales team, after receiving fault feedback, response within 24 hours, 48 hours to give solutions. Outside the warranty period, we also provide lifelong maintenance services, only charging reasonable costs.