Product Description

Experts in high-precision CNC turning, producing copper, stainless steel and specialty parts according to designs. We support all types of custom machining with industrial-grade quality, fast turnaround times, and strict dimensional accuracy. Whether for prototypes or large-scale production, we deliver reliable, tailored solutions to meet the demands of various industries including electronics, automotive, and mechanical engineering.

Workshop & production equipment display

Many years of production experience, professional manufacturing strength certification

Machined parts

Quick delivery from the source factory with minimum order of one piece

Please choose the appropriate processing material according to your actual needs and part properties.

|

|

|

Aluminum | Copper | Stainless steel |

|

|

|

Nylon | Pom | ABS |

Product Display

Real shot display of machined parts

Customized according to drawings, quality assurance, fast proofing

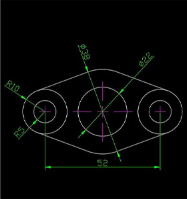

Dimensional drawing

DRAWING REQUIREMENTS

You need to provide CAD files and 3D model files

The file format is as follows

|

|

Precision parts processing

3D model formats: STEP, IGS, XT, PRT and other 3D formats

|

|

Four major advantages

Customized according to drawings, single-piece order, fast proofing

|

|

Technological innovation | Processing Speed |

|

|

Product Quality | Highty Confidential |

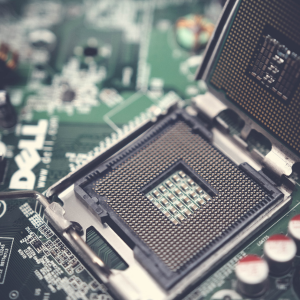

Wide range of applicable industries

|

|

|

|

AEROSPACE | NEW ENERGY FOR CARS | MEDICAL | INDUSTRIAL AUTOMATION |

|

|

|

|

SEMICONDUCTOR | SMART FURNITURE | SPORTS EQUIPMENT | 3D PRINTERS |

Product parameters

| Attribute | Value |

| Minimum wall thicknesses can be processed | 120mm |

| Threaded hole diameters can be machined | 5mm |

| Size Range | Diameter: 1–300 mm, Length: up to 1000 mm (depending on machine capability) |

| Drawing Format | STEP, IGS, XT, PRT |

| MOQ (Minimum Order Qty) | 1 piece (for samples) or based on project requirements |

| Lead Time | 3–15 days (depending on quantity and part complexity) |

| Inspection | CMM, Caliper, Gauge, Surface Roughness Tester |

| Application Industry | Automotive, Medical, Electronics, Aerospace, Machinery |

PART OF THE PROCESSING EOUIPMENT

|

|

Radial drilling machine | CNC wire cutting machine |

|

|

CNC machine tool | Horizontal machining center |

|

|

Surface grinder | CNC lathe |

Custom Process

Consult customer service

Confirm drawings

Online quotation

Confirm order

Processing and produetion

Packaging and delivery

Confirm receipt

Five-star praise

Purchase Notice

1、Our company specializes in non-standard customization, processing according to drawings and samples, no stock, please be advised!

2、The prices of all products in this store are not the actual prices of the products. Please consult the customer for quotation verification before placing an order. Orders placed without contact will be deemed invalid orders and will not be shipped. Please be aware of this and thank you for your cooperation.

3、If the customer does not respond to you in time, you can leave a message with your email and phone number and we will contact you later, or you can call us.

4、If it is not customized according to the customer's drawings, we will replace it for free and bear the domestic round-trip freight.

5、Quickly make samples in 3 days, and the minimum batch trial production can be 5 days, with fast delivery.

6、Customize strictly according to the dimensions on the drawings. If there are tolerance problems, we will replace it free of charge.