Product Description

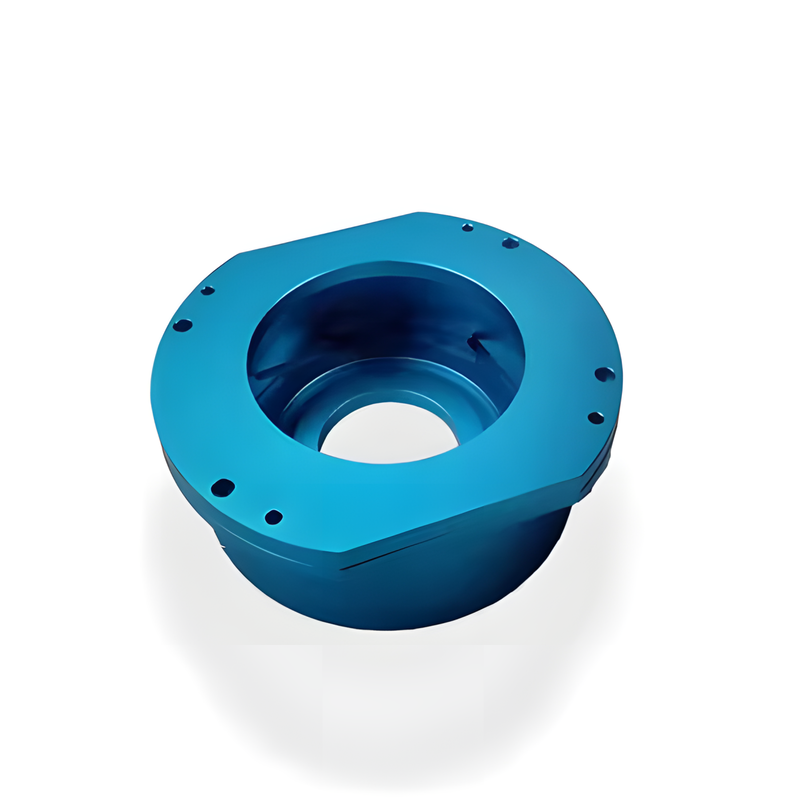

Our Aluminum Surface Treatment – Spray Paint Service offers high-quality painted finishes for aluminum parts. The process includes advanced surface preparation, professional-grade priming, and precise spray coating to achieve durable, uniform, and visually appealing results.

We specialize in color consistency, adhesion strength, and weather resistance, making our services ideal for both indoor and outdoor aluminum applications. Whether you require branding, decorative finishes, or corrosion protection, we provide full-service support from surface prep to packaging.

Key Features

| Smooth, Even Coating | Consistent color and texture with no drips or blemishes |

| Custom Colors | RAL, Pantone, or customer-supplied samples |

| Strong Adhesion | Industrial-grade primers ensure paint bonds securely to aluminum |

| Corrosion & UV Resistance | Coatings designed for long-term performance |

| Aesthetic Options | Matte, gloss, satin, metallic, or textured finishes |

| Eco-Friendly Paint Systems | Low-VOC and RoHS-compliant options available |

Optional processes

Spraying process

Painting process

Baking paint process

Product Display

Application

Spray painting processing for various materials, with a wide range of applications and suitability for multiple industries.

Lamps and lanterns | Household appliances | Kitchen supplies | Plastic accessories | Hardware accessories | Other industries |

Product parameters

| Attribute | Specification |

| Material | All aluminum grades (e.g., 6061, 5052, 1100, 3003) |

| Paint Thickness | 20–50 µm (primer + top coat) |

| Available Colors | RAL, Pantone, or custom |

| Finish Types | Matte, Satin, Gloss, Metallic, Texture |

| Weather Resistance | UV & corrosion resistant paint systems |

| Adhesion Strength | Cross-cut test compliant (ASTM D3359) |

| RoHS/REACH Compliant | Yes |

Custom Process

CONTACT

NEGOTIATION

SENT SAMPLE

TRANSPORTATION

Quality Control

Spray Booth with Filtration Ensures clean, dust-free painting environment |

Curing Oven Thermal curing for solvent-based or powder coatings |

Ultrasonic Cleaner Removes oil, dust, and contaminants before painting |

Paint Thickness Gauge |

Spectrophotometer Verifies color accuracy and consistency |

Surface Roughness Tester Confirms suitable surface profile before painting |

Workshop Display

Quality Assurance

Our Quality Assurance (QA) process ensures the highest standards for spray surface treatment. Here's a summary of key QA practices:

Material Inspection: Incoming materials are checked for alloy composition, cleanliness, and surface integrity.

In-Process Monitoring: Coating thickness, adhesion, and application conditions (e.g., temperature, humidity) are closely monitored in real-time to ensure consistency.

Post-Treatment Testing: Adhesion, coating hardness, and corrosion resistance are verified using standard tests (e.g., ASTM D3359, B117).

Final Inspection: Parts are checked for dimensions, surface finish, gloss, and defects before delivery.

Documentation: Full batch traceability, Certificates of Conformance (CoC), and inspection reports are provided.

Continuous Improvement: Customer feedback and root cause analysis drive ongoing process enhancements.

Our QA program follows ISO 9001:2015 standards, ensuring reliable, high-quality spray coatings for all applications.

Our advantages

Precise customization · Efficient delivery:

Six core advantages of non-standard customization

Manufacturer supply | Customization | Multiple techniques | Quality assurance | Fast delivery | After-sales support |

FAQ

1. What is Spray Surface Treatment?

Spray Surface Treatment is a finishing process where a protective coating is applied to metal surfaces using spray techniques. It improves the durability, aesthetics, and corrosion resistance of CNC-machined parts, with options for various coating types like epoxy, polyurethane, and powder coating.

2. Which metals can be treated with this service?

This service is typically used for aluminum, stainless steel, titanium, magnesium, and zinc alloys. It’s suitable for a wide range of industries, including aerospace, automotive, and electronics.

3. How long does the coating last?

The longevity of the coating depends on factors such as the type of coating, environmental exposure, and maintenance. With proper care, the treatment can last between 5 to 20 years, offering high resistance to wear, corrosion, and environmental damage.

4. Can I choose the color or finish for my parts?

Yes, we offer a variety of color options, including custom Pantone shades, and different surface finishes like matte, satin, glossy, and textured. This flexibility ensures that the treatment meets both functional and aesthetic requirements.

5. Is the process environmentally friendly?

Yes, our spray surface treatment process is environmentally conscious. We use RoHS and REACH compliant coatings, low-VOC spray systems, and adhere to responsible chemical waste management practices to minimize environmental impact.