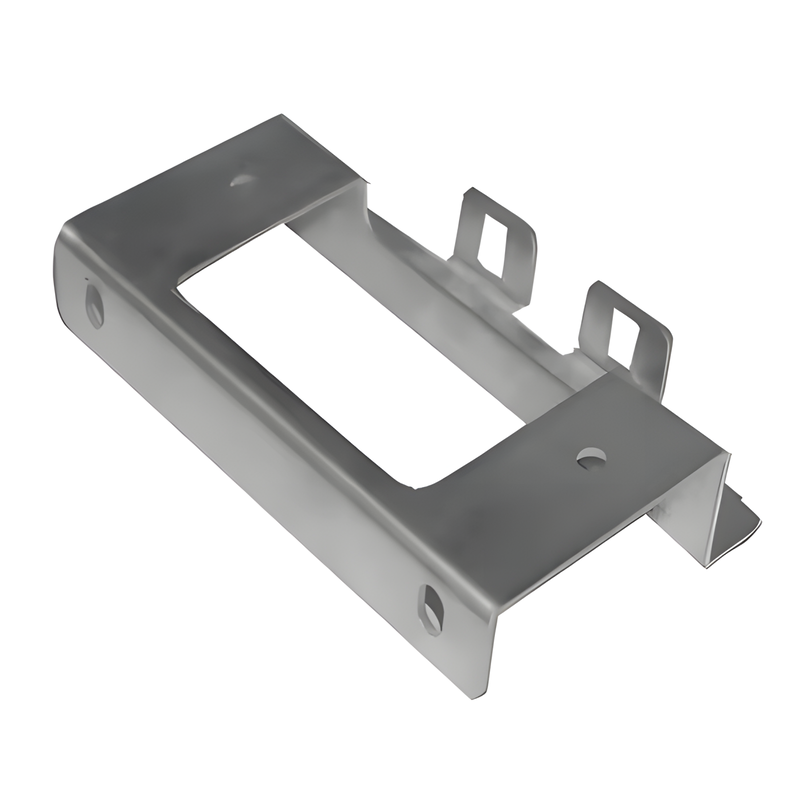

Product Description

In actual production, laser cutting, as a pre-processing step in sheet metal processing (such as precise cutting), when combined with other methods, can achieve greater value:

◆Laser cutting offers high-precision and complex-shaped material removal, solving the problem of processing irregular parts that traditional stamping molds cannot achieve;

◆The stamping and bending processes in sheet metal processing achieve efficient mass production, balancing precision and cost, and meeting the needs of all scenarios ranging from customization to large-scale production.

Laser cutting is characterized by "precision, flexibility and efficiency", while sheet metal processing is distinguished by "economy, batch production and practicality". The two complement each other, enabling the simultaneous satisfaction of both precision and batch production requirements, and jointly promoting the efficient development of the metal processing industry.

Our aluminium materials and other metal materials possess extremely high precision and reliability, and are suitable for the entire production process ranging from prototype development to large-scale production. We use high-quality laser cutting equipment and sheet metal processing equipment to manufacture sturdy, lightweight and corrosion-resistant metal components, which are highly suitable for applications in industries such as automobiles, electrical electronics, construction and aerospace.

Functional Features

Lightweight yet Strong perfect for components that require reduced weight without compromising durability—such as automotive or aircraft parts. |

High Precision for Complex Parts with intricate shapes and details with high accuracy and repeatability. |

Corrosion-Resistant and Rust-Free environments and ensuring long-lasting product life. |

Advantages

| Benefit | Description |

| Lightweight yet Strong | Aluminum and stainless steel has an excellent strength-to-weight ratio, making it ideal for applications where weight reduction is crucial—such as in automotive and aerospace components. |

| Corrosion Resistant | Aluminum and stainless steel does not rust, making it suitable for outdoor or humid environments. |

| Supports Complex Forming | Aluminum and stainless steel offers high flexibility and can be stamped into complex shapes without cracking. |

| High Precision | Modern machinery enables the production of parts with consistent accuracy and fine details. |

| Scalable Production | Suitable for both prototypes and high-volume manufacturing, offering cost-effective per-unit pricing. |

| Finish-Ready Surface | Aluminum and stainless steel can be anodized, painted, or surface-treated for enhanced aesthetics and durability. |

| Comprehensive Secondary Services | Full support for bending, drilling, welding, cutting, and assembly—all in one place. |

Application

Automotive |

Electric |

Heat Protection |

Constructure |

Medical |

Design |

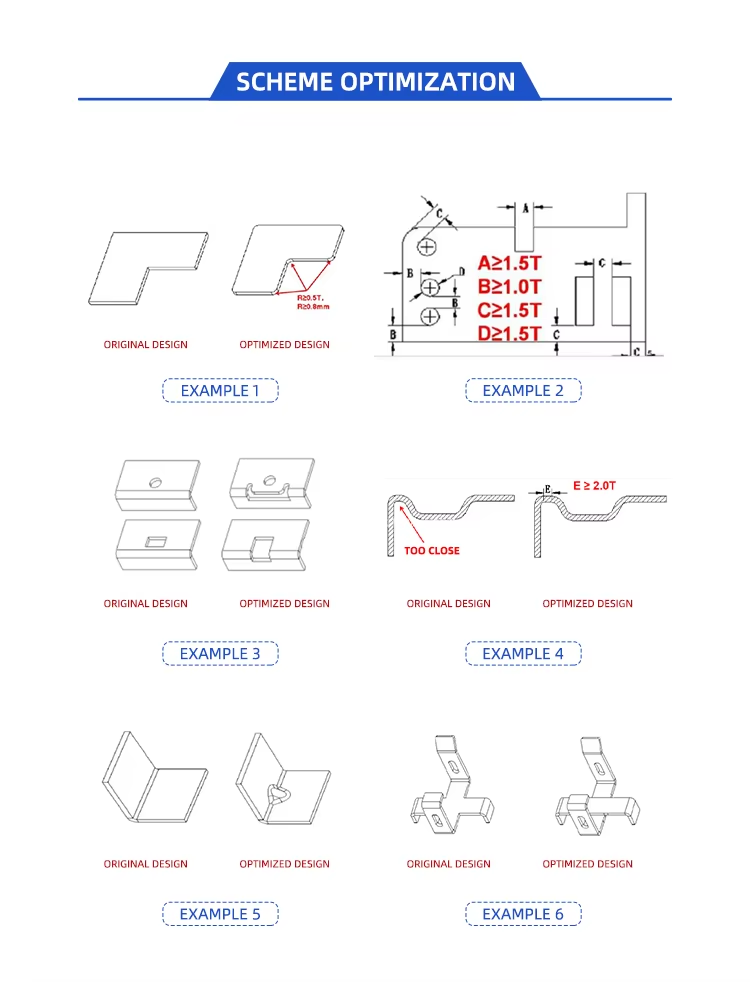

Optimization comparison

Product parameters

| Parameter | Specification / Options | Parameter | Specification / Options |

| Material Grades | 304, 316, 201, 430, Duplex, or as specified by customer | Edge Treatment | Deburred, chamfered, or as specified |

| Sheet Thickness Range | 0.5 mm – 6.0 mm (other thicknesses available on request) | Hole and Slot Tolerance | ±0.05 mm (depends on thickness and method) |

| Maximum Sheet Size | Up to 1500 mm × 3000 mm (custom sizes available) | Corner Radius | Custom per drawing; typically ≥ 0.5 mm for formed parts |

| Tolerances | ±0.1 mm (standard), tighter tolerances available for precision parts | Bending Radius | Minimum 1× material thickness (varies with grade and thickness) |

| Cutting Methods | Laser cutting, CNC punching, shearing | Coating Options | Optional protective film, anodizing (on request for other metals) |

| Forming Techniques | Bending (up to 120°), rolling, deep drawing | Production Volume | Prototyping to high-volume production |

| Welding Options | TIG, MIG, spot welding, seam welding | Compliance Standards | ISO 9001, RoHS, REACH, or per customer requirement |

| Surface Finishes | Brushed (No. 4), Mirror (No. 8), Satin, Bead-blasted, Powder-coated | Lead Time | Typically 7–15 working days (varies by complexity and volume) |

Custom Process

Question

Quotation

Mass Production

Transportation

Quality Control

Raw Material Inspection

Material certification check (e.g. grade 304, 316)

Surface condition: no rust, pitting, or deformation

Thickness verification using calipers or micrometers

| Process | QC Checks | Tools |

| Cutting | Dimension, edge quality, tolerance (±0.1 mm or better | Caliper, measuring tape |

| Punching | Hole diameter, position, burr control | Pin gauge, visual inspection |

| Bending | Angle accuracy, crack-free bends | Protractor, angle gauge |

| Welding | Strength, cleanliness, penetration, visual defects | Weld gauge, visual, NDT (if required) |

| Surface Finish | Uniformity, grain direction, absence of scratches or blemishes | Visual, roughness tester |

Final Inspection

Dimensional inspection against CAD drawings or sample

Assembly test (if applicable)

Surface finish inspection

Cleanliness (no oil, fingerprints, or dust)

Labeling and packaging inspection

FAQ

| Question | Answer |

| What thickness of aluminum can you handle? | We support thicknesses from 0.2 mm to 6.0 mm, depending on the part design. |

| How long does production take? | Typically 7–21 business days, depending on part complexity and order volume. |

| Do you accept small quantity orders or only large batches? | We support both prototype development and mass production. |

| Do you provide die design services? | Yes, we offer CAD/CAM design services and expert consultation by experienced engineers. |

| Do you offer surface finishing services? | Yes, we offer anodizing, painting, deburring, polishing, and various surface treatments. |