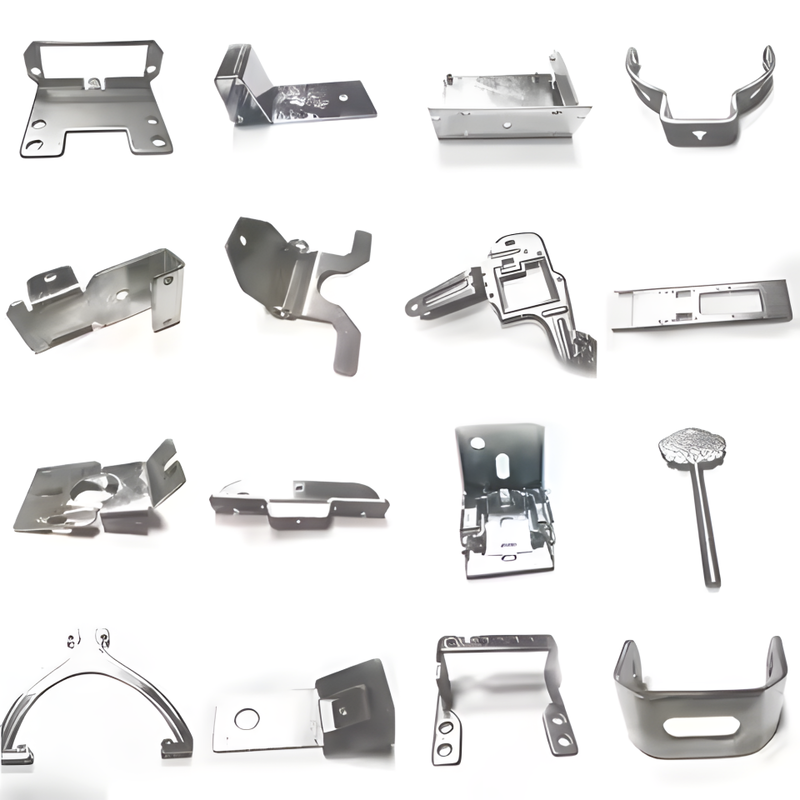

Product Description

Our Sheet Metal Stamping Service delivers high-quality, custom metal components with precision engineering and cost-effective production. Utilizing advanced stamping presses and dies, we transform flat sheet metal into complex, high-strength parts for a wide range of industries including automotive, aerospace, electronics, construction, and appliances.

Service Features

| Material Capabilities | Aluminum, stainless steel, carbon steel, copper, brass, and specialty alloys |

| Stamping Type | Progressive die stamping, deep draw stamping, transfer stamping, compound die stamping |

| Thickness Range | 0.2 mm to 10 mm (customizable based on requirements) |

| Tolerance | Tight tolerances up to ±0.01 mm |

| Production Volumes | Prototyping to high-volume production runs |

Capabilities:

High-speed stamping presses (up to 600 tons)

In-house tool and die design and fabrication

Secondary operations: deburring, tapping, welding, surface finishing, and coating

ISO-certified quality management system

CAD/CAM-assisted design support for custom parts

Benefits:

High Precision & Consistency: Repeatable results across thousands of parts

Cost-Effective Mass Production: Reduce unit costs for large orders

Material Efficiency: Minimal waste due to optimized die design

Customization: Tailored solutions to meet unique design and functionality needs

Functional Features

| High Dimensional Precision | Maintains tight tolerances in both simple and complex shapes, ensuring consistency across production batches. |

| Material Efficiency | Optimized to minimize material waste during forming, especially with high-volume production |

| Complex Geometry Capability (Deep Drawing) | Ideal for producing deep, hollow, or cylindrical parts without the need for welding or multiple assembly processes. |

| High Strength and Structural Integrit | Deep drawing work-hardens the material, improving strength without additional processes. |

| Wide Material Compatibilit | Applicable to various metals: stainless steel, carbon steel, aluminum, brass, copper, and coated metals. |

| Cost-Effective for Mass Production | Once tooling is set up, it offers low cost per unit, making it suitable for large production runs. |

| Repeatability and Consistency | Capable of producing thousands to millions of identical parts with uniform quality. |

| Versatile Applications | Used in automotive (fuel tanks, housings), medical devices (surgical trays), electronics (enclosures), appliances, and industrial parts. |

| Surface Finish Options | Compatible with secondary surface treatments like polishing, plating, anodizing, and painting. |

| Scalable Prototyping to Production | Suitable for both prototyping and full-scale production with flexible tooling options. |

Customized non-standard products

Multiple specifications and models are available for selection

The manufacturer produces and supplies, supporting customized production as per customer requirements, to meet their needs

Carefully refine every detail

①Selecting high-quality materials, with a short production cycle, and ensuring delivery within the agreed-upon time frame.

② Utilize mature production techniques and strictly control every step of the process.

Application

AUTOMOTIVE |

MEDICALS |

AERODYNAMIC |

|

Product parameters

| Parameter | Details | Parameter | Details |

| Product Name | Deep Draw Metal Stamping & Sheet Metal Stamping Parts | Production Capacity | Up to 1,000,000 parts/month (depending on complexity and part size) |

| Process Type | Deep Draw Metal Stamping / Sheet Metal Stamping | Tooling Type | Custom Tooling for Deep Draw and Progressive Stamping Dies |

| Material Options | Stainless Steel, Carbon Steel, Aluminum, Brass, Copper, Coated Metals, or Custom | Lead Time | 7–25 days (depending on order size and customizations) |

| Material Thickness | 0.3 mm – 6.0 mm (varies by material and application) | MOQ (Minimum Order) | Typically 1,000 pcs (may vary based on design complexity) |

| Tolerance | ±0.01 mm (depending on design complexity) | Design Support | CAD/3D Models, Prototyping, Reverse Engineering, Material Selection Assistance |

| Max Drawing Depth | Up to 10 times the material thickness (depending on material and part design) | Quality Standards | ISO 9001:2015, IATF 16949 (optional for automotive) |

| Surface Treatment | Zinc Plating, Nickel Plating, Chrome Plating, Anodizing, Powder Coating, Polishing | Application Industries | Automotive, Electronics, Appliances, Medical Devices, HVAC, Industrial Equipment, Aerospace |

Custom Process

Understand the customization requirements | Quotation request | Make payment for goods | Prepare sample drafts | Make mold and take samples |

Sample confirmation | Production of regular quantity | Delivery | Confirm receipt of goods | After-sales service |

Quality Control

| Stage | Inspection Method | Purpose |

| Incoming Material Check | Certificate of Material (CoC), hardness testing, thickness measurement | Ensure raw material meets customer and production requirements |

| Tooling & Die Inspection | Dimensional check, trial run verification | Validate tool accuracy before production |

| First Article Inspection | Full inspection of initial part using CAD comparison, CMM, or manual gauges | Confirm setup correctness and baseline part conformity |

| In-Process Inspection | Random sampling, SPC (Statistical Process Control), inline dimensional checks | Monitor quality consistency throughout production |

| Draw Depth Verification | Depth gauge, sectioning test (if needed) | Ensure forming depth accuracy and material stretch limits |

| Surface Quality Check | Visual inspection, coating thickness test, salt spray test (for corrosion parts) | Confirm finish quality and coating durability |

| Dimensional Accuracy | Calipers, micrometers, height gauges, CMM | Validate tolerances and fit with mating parts |

| Final Inspection | Lot-based inspection, customer checklist verification | Ensure outgoing product matches specifications |

| Packaging QC | Quantity check, protective packaging validation | Prevent defects or damage during handling and shipment |

Inspection Equipment Used

CMM (Coordinate Measuring Machine)

Optical Comparator

Surface Roughness Tester

Coating Thickness Gauge

Vernier Calipers, Micrometers

Depth Gauges & Profile Projectors

Salt Spray Tester (for corrosion resistance validation)

Factory shooting footage

FAQ

Q1:Where can I get product&price information? A1:Send us e-mail , we will contact you as we receive your mail.

Q2: How soon can I get samples? A2: Depending on your specific project, it usually takes 7 to 15 days.

Q3:How to enjoy the OEM services? A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you after your agreement, and we produce for you.

Q4:what is the process to place the order? A4: send us the drawings to get a free quotation.And we will make a sample for you to check the quality.Then batch production will be proceed after sample is qualified and our service is accepted.

Q5: Is it possible to know how are my products going on without visiting your company? A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.