Product Description

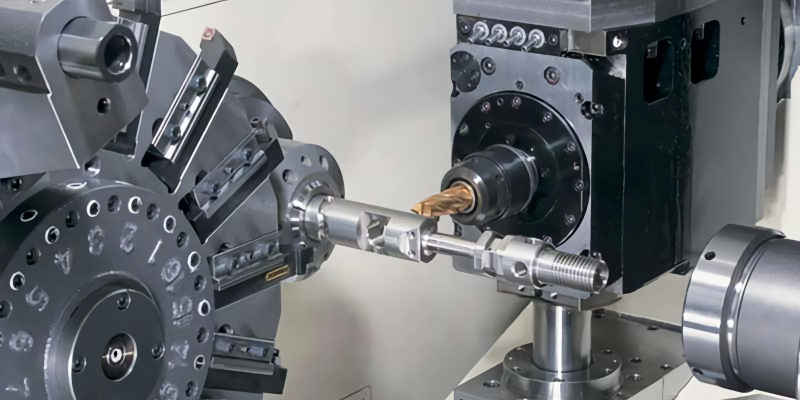

Custom-engineered cemented carbide components produced through non-standard precision machining and Swiss-type CNC processes. Designed for high-strength, high-precision performance in complex industrial applications, these parts ensure exceptional dimensional stability and wear resistance. Ideal for continuous, high-speed operations under tight tolerances, minimizing maintenance and maximizing production efficiency in demanding environments.

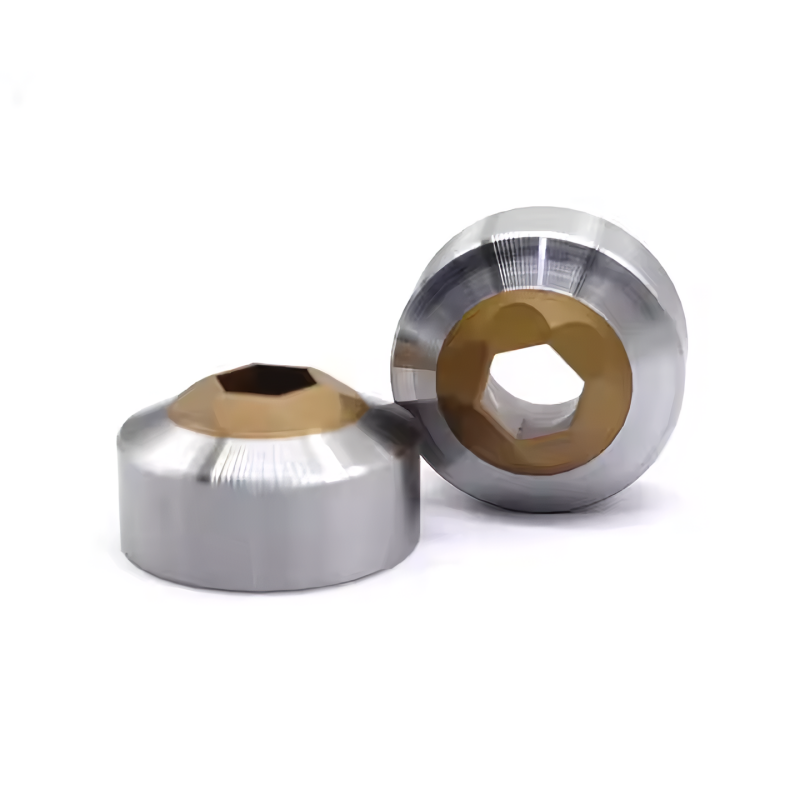

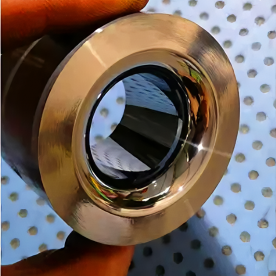

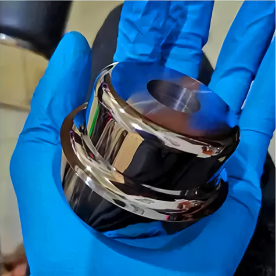

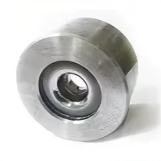

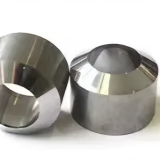

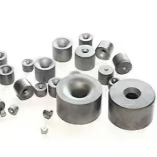

Tungsten steel mold

Wear-resistant and durable

Non-standard customized alloy molds

Good quality and fast delivery

Tungsten Steel Blank – Ideal for Non-standard Precision Machining & Swiss-type CNC Machining

A Tungsten Steel Blank is a semi-finished raw material made from cemented carbide (tungsten carbide), widely recognized for its exceptional hardness, wear resistance, and dimensional stability. These properties make it perfectly suited for high-precision machining applications where strength, accuracy, and durability are essential.

Role in Non-standard Precision Machining

Non-standard precision machining involves the fabrication of custom or complex parts that fall outside standardized dimensions or designs. These are typically used in:

-Specialized machinery components

-Precision molds and tooling

-Aerospace and medical instruments

-High-tolerance industrial parts

Tungsten steel blanks serve as the starting material for CNC processes such as milling, turning, grinding, EDM, and multi-axis machining. Their superior mechanical properties allow them to maintain tight tolerances and structural integrity even under intense cutting pressure, heat, or vibration.

They are ideal for low- to mid-volume custom parts that demand dimensional consistency and extended tool life.

Role in Swiss-type CNC Machining

Swiss-type CNC machining is a process designed for producing small, slender, and complex components with very tight tolerances. The use of tungsten steel blanks in this setup is particularly beneficial due to:

-High rigidity, which helps prevent bending or deformation during high-speed turning

-Superior surface finish, essential for medical and electronic parts

-Compatibility with multi-axis operations, reducing the need for secondary processing

Common applications include:

-Precision shafts

-Micro fasteners

-Surgical pins and implants

-Electrical connector components

Made with care, safe to use

This product has carefully selected materials and stable performance. It can be customized according to drawings.

Not easy to corrode, high hardness Aluminum nail body and carbon steel nail core Combined with smooth surface. |

|

Smooth finish, no burrs Aluminum nail body and carbon steel nail core Combined surface is smooth. |

|

Various specifications can be customized Good corrosion resistance when exposed to harsh environments, Environmentally friendly materials, safe to use. |

|

Scope of application: Widely used in water engineering, chemical engineering, electricity, urban construction and other industries

|

|

|

Water supply project | Petrochemical Engineering | Chemical Engineering |

|

|

|

Power Industry | Agricultural irrigation | Urban Construction |

Product Display

|

|

|

|

|

|

|

|

|

|

Information Required for Quotation & Production

For Non-standard Precision Machining / Swiss-type CNC Machining

Product Drawing / CAD File

File formats: STEP, STP, IGS, PDF

If unavailable, please provide sketches with dimensions or reference photos

Material Specification

e.g., Aluminum 6061, Brass C3604, Stainless Steel 304, POM, Peek, etc.

If unsure, describe the part’s application so we can suggest a suitable material

Required Quantity

Prototypes / Small Batch / Mass Production

Tolerance Requirements

e.g., ±0.01 mm or specify critical tolerance zones

Part Application / Function

Describe where or how the part will be used (e.g., packaging machine, automation system, medical device)

Surface Finish / Heat Treatment

e.g., Anodizing, Nickel Plating, Sandblasting, Black Oxide, etc.

Lead Time Requirement

Preferred delivery date or urgency

Contact Information

Name, Email, Phone Number, Shipping Address

Why Choose Us

Your Professional, Precise, and Trusted CNC Machining Partner

· Over 10 years of manufacturing experience

Skilled in handling a wide range of materials and small-batch customizations with consistent quality.

· Advanced precision equipment

Equipped with high-precision machines such as 5-axis CNC centers and 3D coordinate measuring machines (CMM).

· Fast quality inspection and reliable after-sales support

Every part is efficiently inspected to ensure quality and give customers confidence after delivery.

· One-stop service from design to mass production

Supporting all stages from prototype design to industrial-scale manufacturing.

Product parameters

Parameter | Details |

Machining Type | CNC Machining, Broaching, Drilling, Laser Machining, Milling, Turning, etc. |

Micro Machining | Yes |

Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, Plastic |

Available Materials | Stainless Steel, Aluminum, Brass, ABS, POM, Delrin, Acetal, Nylon |

Surface Treatment | Anodizing (Oxidation), Powder Coating, Sandblasting, Brushing, Painting |

Color | Customized Color Options Available |

Processing Equipment | CNC Machining Machines |

Application | Industrial Equipment |

Tolerance | ±0.01 mm |

Certification | ISO 9001:2008 |

MOQ | 1 Piece |

Model Number | FZ-01 |

Service | Customized OEM CNC Machining |

Custom Process

Consult customer service

Confirm drawings

Online quotation

Confirm order

Processing and produetio

Packaging and delivery

Confirm receipt

Five-star praise