Product Description

Various Specifications

Customization Available Based on Designs and Samples

Extensive Industry Experience, Suitable for a Wide Range of Industries

High Quality, Excellent Service, and High Value

6 Advantageous Features

Six major advantages provide you with a better user experience

Stainless steel Various specifications Accurate precision Excellent quality Durable Professional customization

Features

Rigorous craftsmanship

Stable structure, smooth surface

Burr-free, uniform stress distribution

No bumps or irregularities on the surface

Selected Raw Materials

Used throughout the product

Stainless Steel

High Hardness and Toughness

Customization Available

Wide Variety of Styles

Customizable to Customer's Needs

Customization Available Based on Drawings and Samples

Product Display

Application

Widely applicable across multiple industries

Parts processing for automotive, communications equipment, aviation, hardware accessories, and more

Automotive industry Aviation industry Electronic equipment Hardware tool Shipbuilding industry Factory equipment

Automotive industry Aviation industry Electronic equipment Hardware tool Shipbuilding industry Factory equipment

accessories accessories industry accessories accessories accessories

Product parameters

Name | Specifications | Name | Specifications |

Item | Customized non-standard parts | Processable Materials | Stainless steel/aluminum alloy |

Features | Strong and durable / Quality assured | Processing Equipment | CNC machine tools, CNC Swiss lathes |

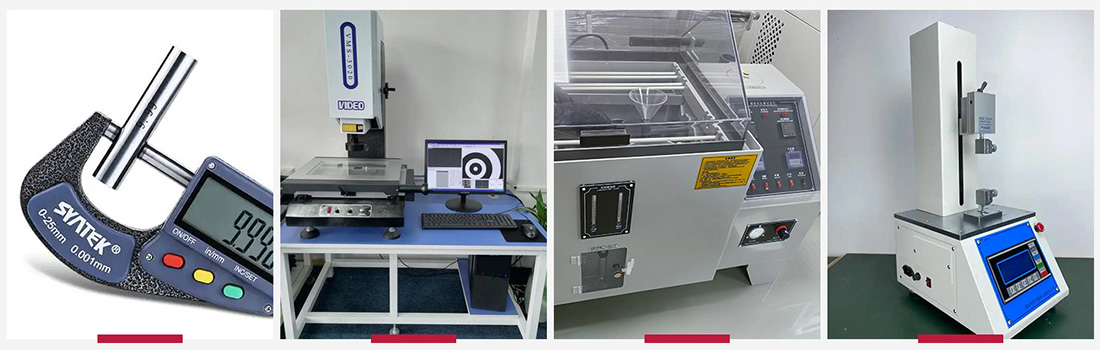

Accuracy | ±0.01mm | Testing Equipment | Micrometer, 2D testing, salt spray testing, tensile testing |

Custom Process

Online communication

Confirm requirements

Product Quote

Sample drawing

Pay a deposit

Order processing

Pay the balance

Confirm shipment

Quality Control

Engineering Department

Edit and confirm drawings and process

Regular technical seminars

Technical Team

Regular technical seminars

Solve customer processing technology issues

Professional Customer Service

One-on-one service

Quickly resolve product issues

Quality Assurance

Confirm shipment with a professional quality inspection team

Fully inspected for workmanship, with a tolerance of ±0.01°C. Third-party inspection available.

01Testing instruments and equipment

micrometer Second dimension test Salt spray test Tensile test

02Testing process

Incoming material First piece of Process quality Supervisor inspection First inspection of Full inspection of

inspection process inspection shipment shipment

03Inspection room/test room

production equipment

Serve

Quality and service go hand in hand

Fast Prototyping Physical Factory Customization is available Sufficient stock Luhou Consulting

Assured Quality Integrity upon request. Fast delivery Consult anytime

Frequently Asked Questions

Detailed communication?

Before ordering, communicate with the supplier in detail to clarify the specific requirements for the part, including material, size, shape, precision, surface finish, etc. This will help prevent products that don't meet expectations due to unclear requirements.

Product problem?

All products are custom-made. Please contact customer service before placing an order. Customized products are made according to the individual needs of consumers and are unique. They are usually not available for secondary sale. Returns and refunds are not supported after placing an order. Please understand! If there are quality problems with customized products, consumers have the right to request the merchant to repair/exchange them.

How to resolve issues?

If any issues are discovered during the inspection process, we will promptly contact the supplier and discuss solutions, such as rework or repair, to ensure that the issue is properly resolved.