Product Description

One-stop hardware machining and parts custom production

Swiss-type CNC machining parts series

• Complete specifications • Quick sample delivery • High precision

Welcome to consult

Swiss-type CNC machining is a unique structure supported by spindle movement and guide bushings, specializing in large-scale, ultra-high precision, one-time forming production of small, slender, complex shaft parts — a cutting-edge manufacturing technology.

Functional Features

Product specifications are diverse and support customization

Strong technical accumulation, excellent product quality

Using rigorous manufacturing processes

Smooth and beautiful surface with metallic luster

Strict selection of raw materials

Higher hardness, better materials, not easy to deform

Product Display

Source factory, quality assurance, genuine materials

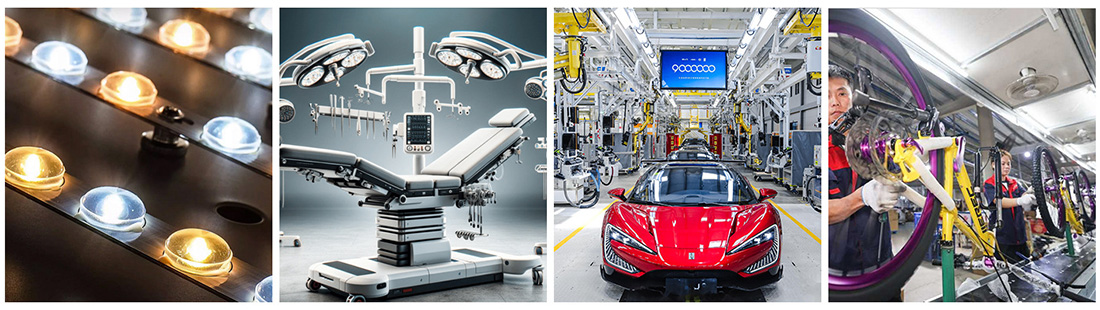

Application

Products are widely used in various fields such as

electronics, electrical appliances, lighting, locomotives, medical, aerospace, new energy, etc.

| LED | Medical | Automobile | Bicycle parts |

| Power connectors | Electronics | Aerospace | Subway |

Product parameters

Item | Details | Item | Details |

Name | Custom non-standard parts | Materials | Stainless steel / Aluminum alloy |

Features | Sturdy and reliable / Quality assured | Equipment | CNC machine tools, Swiss-type CNC machines |

Accuracy | ±0.01mm | Inspection | Micrometer, 2D tester, salt spray test, tensile test |

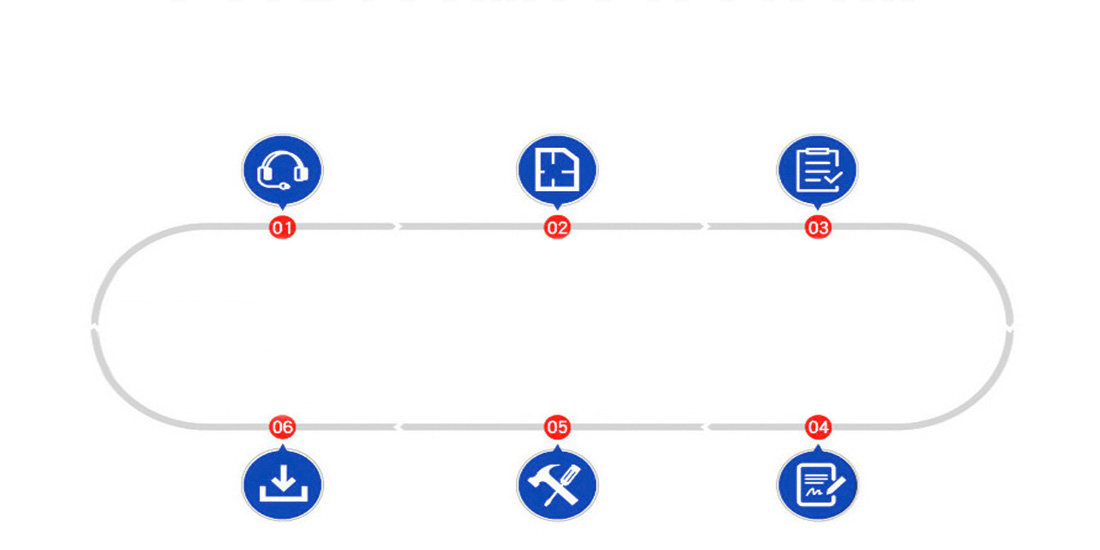

Customization Process

Custom service exclusively for you,

providing a one-stop solution

Requirements Drawings Confirm samples

After-sales service Arrange custom production Sign contract

Professional Team

Professional team with rich machining experience

Engineering Department

Modify and confirm drawings and processes

Regularly hold technical seminars

Technical Team

Hold regular technical seminars

Solve machining technical issues for customers

Professional Customer Service

One-on-one service

Quickly resolve product-related issues

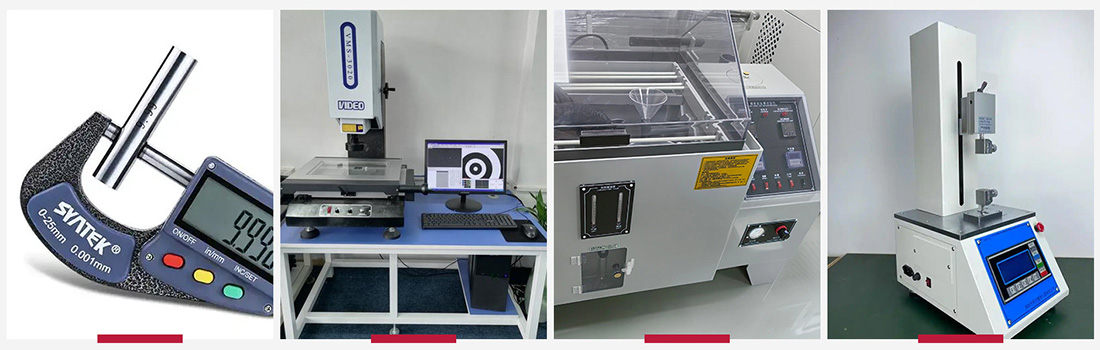

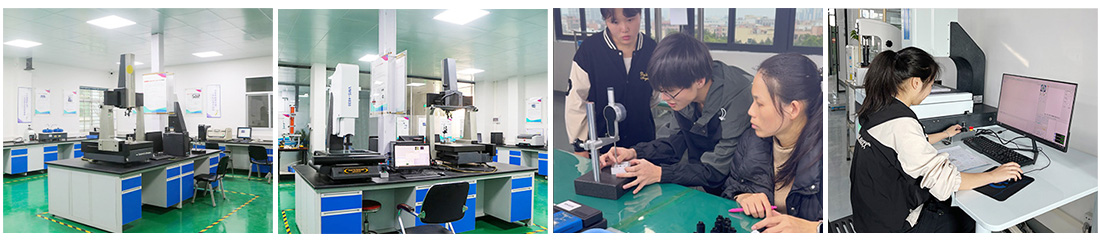

Quality Control

Professional quality inspection team

Full process inspection, tolerance ±0.01mm, supports third-party inspection

01 Inspection Equipment

| Micrometer | Two-dimensional tester | Salt spray test | Tensile test |

02 Inspection Process

| Material inspection | First-piece inspection | Quality control | Supervisor inspection | Pre-shipment | Final shipment |

03 Inspection Room / Test Room

Production Equipment

Our Advantages

Direct factory shipment, no middleman price difference

Real discounts to buyers because we are the manufacturer

Direct supply from manufacturer, no intermediaries

We eliminate all middle steps to directly benefit buyers

Direct supply from manufacturer shortens the distance between factory and buyer

Good quality, guaranteed commitment

We promise: if parts are unusable due to processing issues,

we will repair or remanufacture. Please buy with confidence.

FAQ

Detailed communication?

Communicate in detail with the supplier before customization to clarify specific part requirements, including material, size, shape, accuracy, etc., to avoid product mismatch due to unclear demands.

Product issues?

All products are custom-made. Please contact customer service before placing an order. Customized products are tailored to individual consumer needs, unique, and usually not resellable. No returns or refunds after ordering. Thank you for understanding! If there are quality issues, consumers have the right to request repair or replacement from the seller.

Problem handling?

If issues are found during inspection, contact the supplier promptly to discuss solutions such as rework or repair, ensuring proper resolution.