产品描述

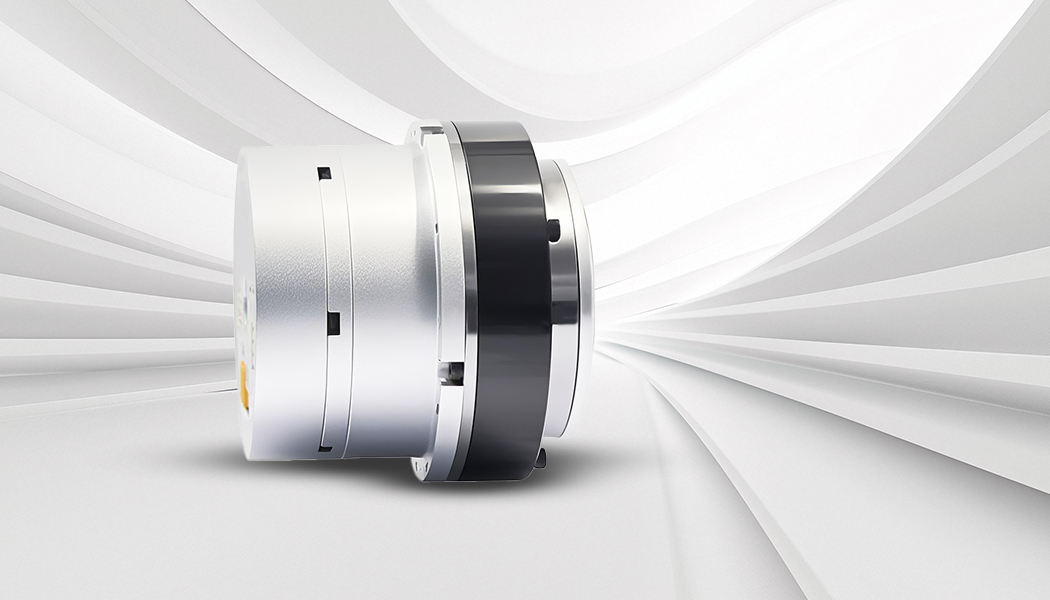

这款关节模组配备100:1高精密减速比,提供大扭矩输出与精准定位。集成无刷电机、高效谐波减速器,具备高刚性、低背隙、长寿命特性,适用于工业机器人、自动化设备等高精度、高负载场景,支持模块化快速集成。

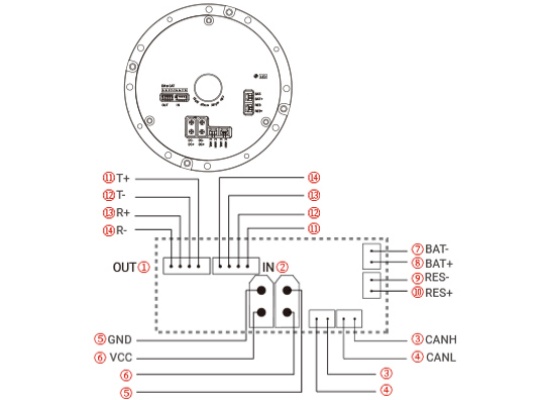

端口定义 | 端口说明 |

①EtherCAT_OUT | EtherCAT 输出 |

②EtherCAT_In | EtherCAT 输入 |

③CAN_H | CAN_H 网络信号端 |

④CAN_L | CAN_L 网络信号端 |

⑤GND | 电源负极 |

⑥VCC | 电源正极 |

⑦BAT- | 多圈电池负极 |

⑧BAT+ | 多圈电池正极 |

⑨RES- | 泄放电电阻口 |

⑩RES+ | 泄放电电阻口 |

⑪ T+ | 主站发送控制命令到模组 |

⑫ T- | 模组发送状态反馈到主站 |

⑬ R+ | 主站反射模组的状态数据 |

⑭ R- | 模组反射主站的控制命令 |

爆炸图

该产品体积紧凑,集成了FOC控制板,高精度多圈绝对编码器,无框转矩电机、精密谐波减速器等主要部件。

1.电机后盖

2.控制委员会

3.编码器

4.定子外壳

5.电动机转子

6.电机定子

7.谐波传动

8.柔性花键盖

谐波一体化关节交叉滚子轴承设计

滚子呈90°交叉排列

使其可承受径向力、轴向力和倾覆力矩

具有高精度、高稳定性、高承载,高刚性的特点

双绝対值编码器

内置双绝对值编码器,全闭环控制

输出端采用17位绝对值编码器,重复定位精度小于0.01度,

可记忆单圈及多圈断电位置,全闭环控制,补偿传动误差,精度无磨损。

通讯协议

EtherCAT, CANopen通讯可选

位置,速度,电流回路PID实时可调

产品参数

参数 | 单位 | EHD - 14 | EHD-17 | EHD-20 | EHD-25 | EHD-32 |

减速比 | - | 100 | 100 | 100 | 100 | 100 |

输入电压 | V | 48 | 48 | 48 | 48 | 48 |

空载转速 | RPM | 30 | 30 | 30 | 30 | 20 |

空载电流 | A | 0.9 | 145 | 2.59 | 1.61 | 3.9 |

额定转速 | RPM | 25 | 25 | 25 | 25 | 18 |

额定转矩 | N.m | 11 | 35 | 50 | 108 | 150 |

额定功率 | W | 100 | 180 | 250 | 400 | 700 |

额定电流 | A | 6.5 | 9 | 13 | 16 | 20 |

峰值扭矩 | N.m | 28 | 54 | 80 | 157 | 229 |

峰值电流 | A | 16.25 | 13.86 | 20.8 | 23.2 | 33.44 |

反电势常数 | Vdc/kgm | 1.39 | 2.79 | 2.79 | 4.89 | 6.28 |

扭矩常数 | N.m/A | 0.02 | 0.04 | 0.04 | 0.07 | 0.09 |

线电阻 | Ω | 0.62 | 0.7 | 0.36 | 0.155 | 0.08 |

线电感 | mH | 0.43 | 0.47 | 0.51 | 0.33 | 0.18 |

极对数 | - | 10 | 10 | 10 | 10 | 10 |

接线方式 | - | Y | Y | Y | Y | Y |

背隙 | Arcsec | - | <20 | <20 | <20 | <20 |

编码器类型及接口 | - | Dual encoder/ABS - 17bit | Dualencoder/ABS-17bit | Dualencoder/ABS-17bit | Dualencoder/ABS-17bit | Dualencoder/ABS-17bit |

重复定位精度 | Degree | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

通信方式 | - | CAN / EtherCAT | CAN /EtherCAT | CAN /EtherCAT | CAN/ EtherCAT | CAN /EtherCAT |

绝缘等级 | - | F | F | F | F | F |

堵转扭矩数据 | ||||

EHD-20 | 扭矩 | 温升 | 堵转时间 | 相电流 |

(N.m) | (℃) | (s) | (Arms) | |

75 | 12 | 15 | 10.5 | |

100 | 8 | 10 | 13.5 | |

125 | 15 | 8 | 18 | |

*1.标准品电机只支持非抱闸。

*2.标准品电机支持CAN总线和EtherCAT。

*3.标准品电机没有防水功能,如需IP54请订单前联系销售。

*4.此产品还支持50:1的减速比,订购前请联系销售确定交期。

*5.额定扭矩测试方法:在环境温度摄氏24度(无其他散热方式)下,在额定转速下进行测试,电机扭矩在温升60度条件下达到温度平衡、可长时间工作点为该电机额定扭矩值。

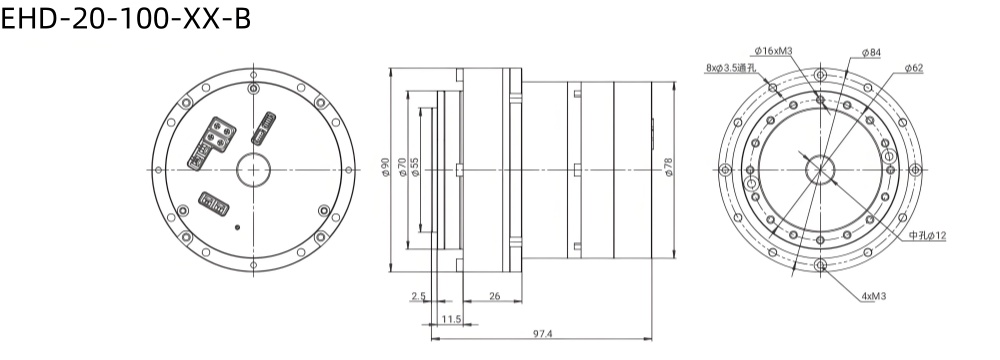

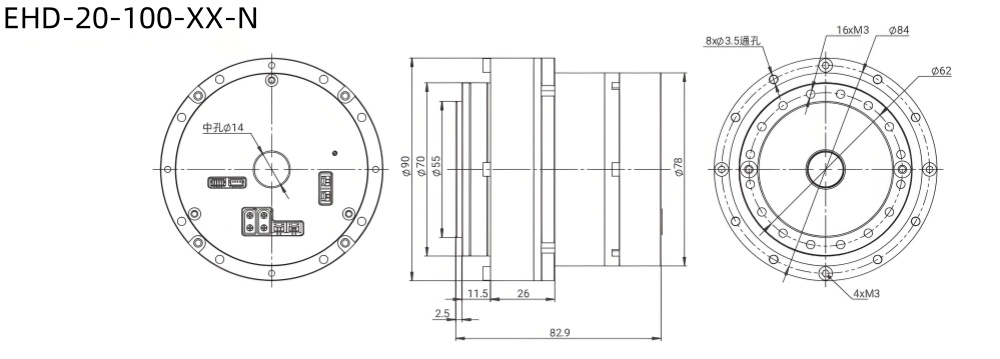

尺寸图

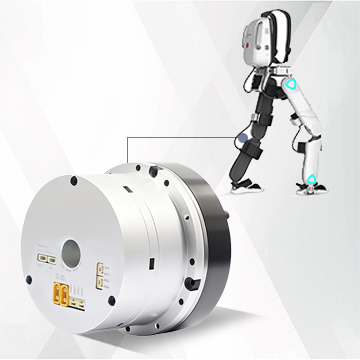

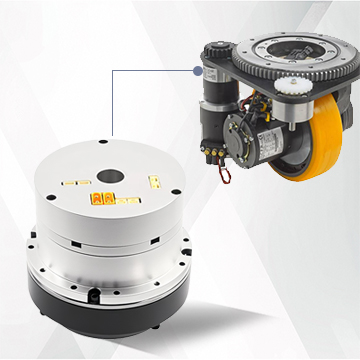

应用

该关节模组是一款高性能的机电一体化驱动单元,集成了高扭矩无刷电机、精密减速器和智能控制系统,适用于机器人关节、自动化设备及工业机械臂等场景。其50N·m的额定扭矩和13A的电流输出,可满足中高负载需求,同时具备高精度、低噪音和长寿命特性。模块化设计支持快速安装与维护,广泛应用于协作机器人、医疗设备、物流分拣及智能制造领域,显著提升设备的动态响应与能效表现。

服务

1. 是否支持防水防尘?防护等级是多少?

是的,我们的关节模组可根据客户需求定制防水防尘功能。 标准款为室内应用型不防水,可选配IP54等级防护,适合一定的户外或潮湿环境使用。

如有更高防护需求(例如IP67),可联系定制。

2. 是否支持减速比定制?

支持。我们可以根据您的应用需求提供不同减速比的定制方案。

常规减速比范围覆盖:10:1 ~ 200:1,具体可根据负载、速度、扭矩要求匹配最佳组合。

3. 单编码器和双编码器版本有什么区别?

单编码器版本监测电机端转动,适用于一般精度要求场合;双编码器版本同时监测电机端和输出端,能有效补偿齿隙和弹性误差,适用于高精度控制和安全要求高的应用(如协作机器人、医疗设备)。

4. 关节模组可以支持哪些通讯接口?

标准版支持模拟量控制(电流/电压指令)或脉冲指令控制;

根据需求,可选配支持CANopen、EtherCAT、Modbus-RTU等工业总线协议(需定制)。

5. 是否支持驱控一体?可以直接连接控制器吗?

我们提供可选的驱控一体版关节模组,内置电机驱动器和位置伺服控制器,

用户可直接通过总线或脉冲接口控制,无需外接独立驱动器,简化布线和系统集成。

6. 有标准的3D模型文件可以下载吗?

有的。我们为所有型号提供STEP格式的三维模型文件,便于客户快速进行机械设计集成。

如需获取,请联系我们销售人员获取下载链接或资料包。

7. 工作温度范围是多少?

标准工作温度范围为:-10°C ~ +50°C。

如需耐低温或耐高温应用环境(如冷库、热作业环境),可以定制特殊温控方案。

8. 关节模组是否可以空心设计?能走线吗?

部分型号是空心轴设计,中心孔径可用于走线、走气管、水管等,便于实现复杂末端执行器的功能布局。

具体中心孔径尺寸请参考型号选型表或咨询客服。

9. 标准交期和定制交期多久?

标准型号交期:通常为7-14个工作日。

定制需求(如减速比定制、通讯协议定制等)交期根据具体要求而定,一般5-10周。

10. 质保期多长?售后服务如何?

所有关节模组产品提供12个月质保期(正常使用情况下)。

我们提供远程技术支持,故障诊断指导,以及快速备件供应服务。质保期外也可提供有偿维修和维护服务。

包装图

包装清单

包装清单

1.电源线*2

2. CAN总线通讯连接线*4

3.120Ω终端电阻*1

4. EtherCAT通讯连接线*2

联系我们