Product Description

Large-aperture incremental encoder - Outer diameter :66mm-90mm through-hole type |

|

| Large-aperture incremental encoder - Outer diameter :100mm-120mm through-hole type |

Large-aperture incremental encoder - Outer diameter :144mm-260mm through-hole type |

|

Product parameters

Large-aperture incremental type braided with an outer diameter of 66mm to 90mm

| ||||

Product series | SAH66H | SAH8OH | SAH90N | SAH90H |

Size (Shell) | Ø66mm | Ø80mm | Ø90mm | Ø90mm |

Spindle size | Through hole:Ø12,15,18, | Through hole:Ø20,25,28, | Through hole:Ø20,25,28,30,35,38,40,45mm | |

Working principle | Optoelectronics | |||

Power supply voltage | 5±0.25 VDC or 10...30VDC | |||

Output circuit | HTL/ push-pull output, TL/RS422, voltage output, current output | |||

Output signal | A B , A B Z or A B Z + A B / Z / | |||

Zero position signal | The width of the Z signal is 1T(can be stacked at 0.5T or 0.25T). | |||

Consumed current | 80mA,(HTL/TL 150mA max.) | |||

Response frequency | 100KHz,150KHz,300KHz | |||

Connection method | Shielded cable or aviation plug | |||

Qualification method | Radial lateral protrusion | |||

Maximum rotational speed | 6000r/min | |||

Main shaft load | 40N radially, 20N axially | |||

Protection grade | IP64 | IP65 | IP65,IP66 | IP65,IP66 |

Starting torque | 3x10-2N.m Max. | |||

Working temperature | -25°....85℃Customizable working temperature: -40° C... ... . 100 ℃) | |||

Storage temperature | -35℃...100℃ | -35℃.….80℃ | -35...100℃ | -35℃...100℃ |

Impact-resistant | 1000m/s²,6ms | |||

Anti-vibration | 100m/s²,10...200Hz | |||

Pulse number | Common pulses 100120125200250256300360400500512600100, 0102, 4120, 0125, | |||

Large-diameter incremental type with an outer diameter of 100mm to 120mm

| ||||

Product series | SAH100 | SAH100N | SAH120 | SAH121 |

Size (Shell) | Ø 100mm | Ø120mm | ||

Spindle size | Through hole:Ø28,30,35,38,40,42,45,48,50,55mm | Through hole:Ø30,38,40,42mm | Through hole:Ø50,55,60,65mm | |

Working principle | Optoelectronics | |||

Power supply voltage | 5±0.25 VDC or 10...30VDC | |||

Output circuit | HTL/ push-pull output, TTL/RS422, voltage output, current output | |||

Output signal | A B , A B Z or A B Z + A B / Z / | |||

Zero position signal | The width of the Z signal is 1T(0.5T or 0.25T are optional) | |||

Consumed current | 80mA,(HTL/TTL150mA max.) | |||

Response frequency | 100KHz,150KHz,300KHz | |||

Connection method | Shielded cable or aviation plug | |||

Qualification method | Radial lateral protrusion | |||

Maximum rotational speed | 3000r/min | 2500r/min | 3000r/min | 2500r/min |

Main shaft load | 40N radially, 20N axially | 40N radially, 20N axially | Radial: 200N, axial: 100N | Radial 100N, axial 50N |

Protection grade | IP66 | IP54 | IP65 | IP54,IP65 |

Starting torque | 5x10-2N.m Max | 8x10-2N.m Max | ||

Working temperature | -25°..80℃(Customizable 40°...) 100 ° ℃) | -40°....100℃ | ||

Storage temperature | -35*C...100℃ | -35C...80℃ | -40°C...100℃ | -40℃..100℃ |

Impact-resistant | 1000m/s²,6ms | |||

Anti-vibration | 100m/s²,10...200Hz | |||

Pulse number | Commonly used pulse: 0 100125200256300360500512600100 0102 4150 0200 0204 8250, | |||

Large-diameter incremental type with outer diameter ranging from 144mm to 260mm

| |||||||||

Product series | SAH144 | SAH145 | SAH180 | SAH260 | |||||

Size (Shell) | Ø144mm | Ø145mm | Ø180mm | Ø260mm | |||||

Spindle size | Through holes: Ø55,60,60,65,70,72,80mm | Through holes:Ø85…110mm | Through holes:Ø135,145mm | ||||||

Working principle | Optoelectronics | ||||||||

Power supply voltage | 5±0.25 VDC or 10...30VDC | ||||||||

Output circuit | HTL/ push-pull output, TTL/RS422, voltage output, current output | ||||||||

Output signal | A B , A B Z or A B Z + A / B / Z / | ||||||||

Zero position signal | The width of the Z signal is 1T(0.5T or 0.25T are optional) | ||||||||

Consumed current | 80mA,(HTL/TTL 150mA max.) | ||||||||

Response frequency | 100KHz | ||||||||

Connection method | Shielded cable or aviation plug | ||||||||

Qualification method | Radial lateral protrusion | ||||||||

Maximum rotational speed | 4500r/min | 2500r/min | 3000r/min | 2500r/min | |||||

Main shaft load | Radial: 80N, axial: 40N | Radial: 80N, axial: 40N | Radial 100N, axial 50N | Radial: 300N, axial: 10N | |||||

Protection grade | IP54,IP65 | IP54,IP65 | IP54,IP65 | IP54,IP65 | |||||

Starting torque | 5×10-2N.m Max | 1×10-1N.m Max | 5×10-1N.m Max | ||||||

Working temperature | 25 °... 85℃(Customizable working temperature -40°...) . 100 ℃) | ||||||||

Storage temperature | -30...100℃ | ||||||||

Impact-resistant | 1000m/s²,6ms | ||||||||

Anti-vibration | 100m/s²,10..200Hz | ||||||||

Pulse number | Commonly used pulse: 500512100, 0102, 4180, 0200, | 1~3600 | 1000~10000 | ||||||

Wiring meter | |||||||||

Colour | white | black | red | green | yellow | pink | blue | orange | Shielding |

Signal | Vcc | 0V | A | B | Z | - | - | - | _1) |

Signal | Vcc | 0V | A | B | Z | A/ | B/ | Z/ | _1) |

Order model code: | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||

Incremental encoder | SAH66H | - | XXX | XX | X | X | X | -X X X X X | -XX | ||

1. Specification series | |||||||||||

SAH80H | - | ||||||||||

SAH90N | - | ||||||||||

SAH90H | - | ||||||||||

2. Shaft dimensions | |||||||||||

012 bushing Ø12mm | 012 | ||||||||||

015 bushing Ø15mm | 015 | ||||||||||

018 bushing Ø18mm | 018 | ||||||||||

020 bushing Ø20mm | 020 | ||||||||||

025 bushing Ø25mm | 025 | ||||||||||

028 bushing Ø28mm | 028 | ||||||||||

030 bushing Ø30mm | 030 | ||||||||||

035 bushing Ø35mm | 035 | ||||||||||

038 bushing Ø38mm | 038 | ||||||||||

040 bushing Ø40mm | 040 | ||||||||||

045 bushing Ø45mm | 045 | ||||||||||

3. Connection form | |||||||||||

A1 cable Ø7mm, 8x2x0.14mm ², 1m | A1 | ||||||||||

8-pin AC plug | AC | ||||||||||

AB plug 12-pin M23 | AB | ||||||||||

4. Qualification method | |||||||||||

R exits radially and laterally | R | ||||||||||

5. Signal output | |||||||||||

6 A+ B+ Z+ and A- B- Z- | 6 | ||||||||||

3 A B Z | 3 | ||||||||||

6. Output circuit | |||||||||||

T 10-30V, HTL push-pull output | T | ||||||||||

E 5V, TTL driver output | E | ||||||||||

F 5-30V, HTL push-pull output (Similar products to replace those used by customers in various oil fields) | F | ||||||||||

7. Pulse count: | |||||||||||

10, 15, 50,100,120,125,200,250,256,300,360,400,500,512,600,1000,1024,1200,1250,1500,1800,2000,2048,2500,3000,3600,4000,4096,5000,8192(8192Customization is available within the pulse range) | 01024 | ||||||||||

8. EX explosion-proof type | |||||||||||

EX explosion-proof encoder EX II 2G Ex ib IIB T4 Gb | |||||||||||

Order model code: | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||

Incremental encoder | SAH100 | - | XXX | XX | X | X | X | -X X X X X | -XX | ||

1. Specification series | |||||||||||

SAH100N | - | ||||||||||

SAH120 | - | ||||||||||

SAH110 | - | ||||||||||

2. Shaft dimensions | |||||||||||

028 bushing Ø28mm | 028 | ||||||||||

030 bushing Ø30mm | 030 | ||||||||||

035 bushing Ø35mm | 035 | ||||||||||

038 bushing Ø38mm | 038 | ||||||||||

040 bushing Ø40mm | 040 | ||||||||||

042 bushing Ø42mm | 042 | ||||||||||

045 bushing Ø45mm | 045 | ||||||||||

048 bushing Ø48mm | 048 | ||||||||||

050 bushing Ø50mm | 050 | ||||||||||

055 bushing Ø55mm | 055 | ||||||||||

060 bushing Ø60mm | 060 | ||||||||||

065 bushing Ø65mm | 065 | ||||||||||

3. Connection form | |||||||||||

A1 cable Ø7mm, 8x2x0.14mm ², 1m | A1 | ||||||||||

8-pin AC plug | AC | ||||||||||

AB plug 12-pin M23 | AB | ||||||||||

4. Qualification method | |||||||||||

R exits radially and laterally | R | ||||||||||

5. Signal output | |||||||||||

6 A+ B+ Z+ and A- B- Z- | 6 | ||||||||||

3 A B Z | 3 | ||||||||||

6. Output circuit | |||||||||||

T 10-30V, HTL push-pull output | T | ||||||||||

E 5V, TTL driver output | E | ||||||||||

F 5-30V, HTL push-pull output (Similar products to replace those used by customers in various oil fields) | F | ||||||||||

7. Pulse count: | |||||||||||

10, 15, 50,100,120,125,200,250,256,300,360,400,500,512,600,1000,1024,1200,1250,1500,1800,2000,2048,2500,3000,3600,4000,4096,5000,8192,10000,16000(16000Customization is available within the pulse range) | 01024 | ||||||||||

8. EX explosion-proof type | |||||||||||

EX explosion-proof encoder EX II 2G Ex ib IIB T4 Gb | EX | ||||||||||

Order model code: | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||

Incremental encoder | SAH144 | - | XXX | XX | X | X | X | -X X X X X | -XX | ||

1. Specification series | |||||||||||

SAH144 | - | ||||||||||

SAH145 | - | ||||||||||

SAH180 | - | ||||||||||

SAH260 | - | ||||||||||

2. Shaft dimensions | |||||||||||

055 bushing Ø55mm | 055 | ||||||||||

060 bushing Ø60mm | 060 | ||||||||||

065 bushing Ø65mm | 065 | ||||||||||

070 bushing Ø70mm | 070 | ||||||||||

072 bushing Ø72mm | 072 | ||||||||||

080 bushing Ø80mm | 080 | ||||||||||

085 bushing Ø85mm | 085 | ||||||||||

090 bushing Ø90mm | 090 | ||||||||||

100 bushing Ø100mm | 100 | ||||||||||

110 bushing Ø110mm | 110 | ||||||||||

135 bushing Ø135mm | 135 | ||||||||||

145 bushing Ø145mm | 145 | ||||||||||

3. Connection form | |||||||||||

A1 cable Ø7mm, 8x2x0.14mm ², 1m | A1 | ||||||||||

8-pin AC plug | AC | ||||||||||

AB plug 12-pin M23 | AB | ||||||||||

4. Qualification method | |||||||||||

R exits radially and laterally | R | ||||||||||

5. Signal output | |||||||||||

6 A+ B+ Z+ and A- B- Z- | 6 | ||||||||||

3 A B Z | 3 | ||||||||||

6. Output circuit | |||||||||||

T 10-30V, HTL push-pull output | T | ||||||||||

E 5V, TTL driver output | E | ||||||||||

F 5-30V, HTL push-pull output (Similar products to replace those used by customers in various oil fields) | F | ||||||||||

7. Pulse count: | |||||||||||

10,15,50,100,120,125,200,250,256,300,360,400,500,512,600,1000,1024,1200,1250,1500,1800,2000,2048,2500,3000,3600,4000,4096,5000,8192,10000,16000(16000Customization is available within the pulse range) | 01024 | ||||||||||

8. EX explosion-proof type | |||||||||||

EX explosion-proof encoder EX II 2G Ex ib IIB T4 Gb | EX | ||||||||||

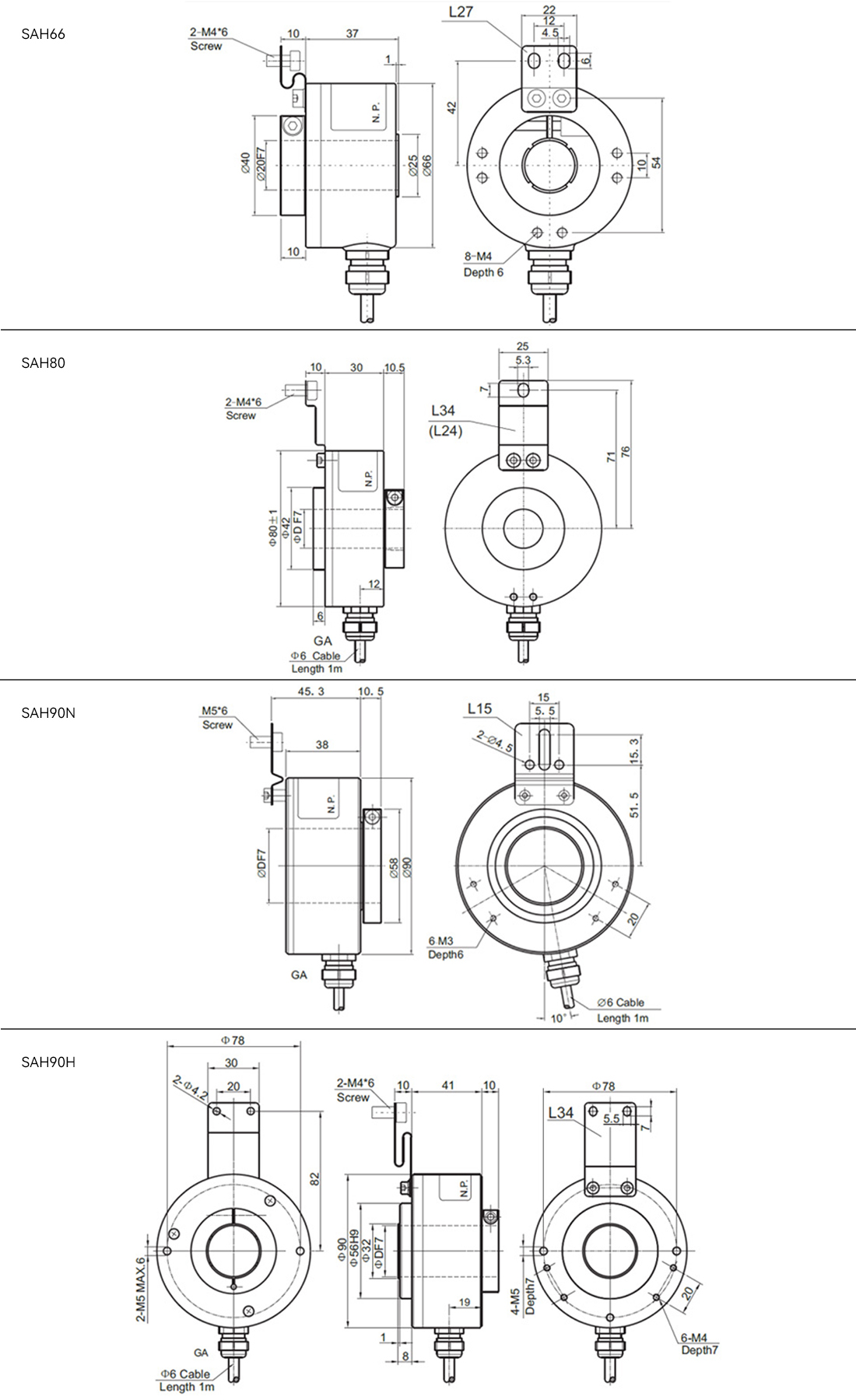

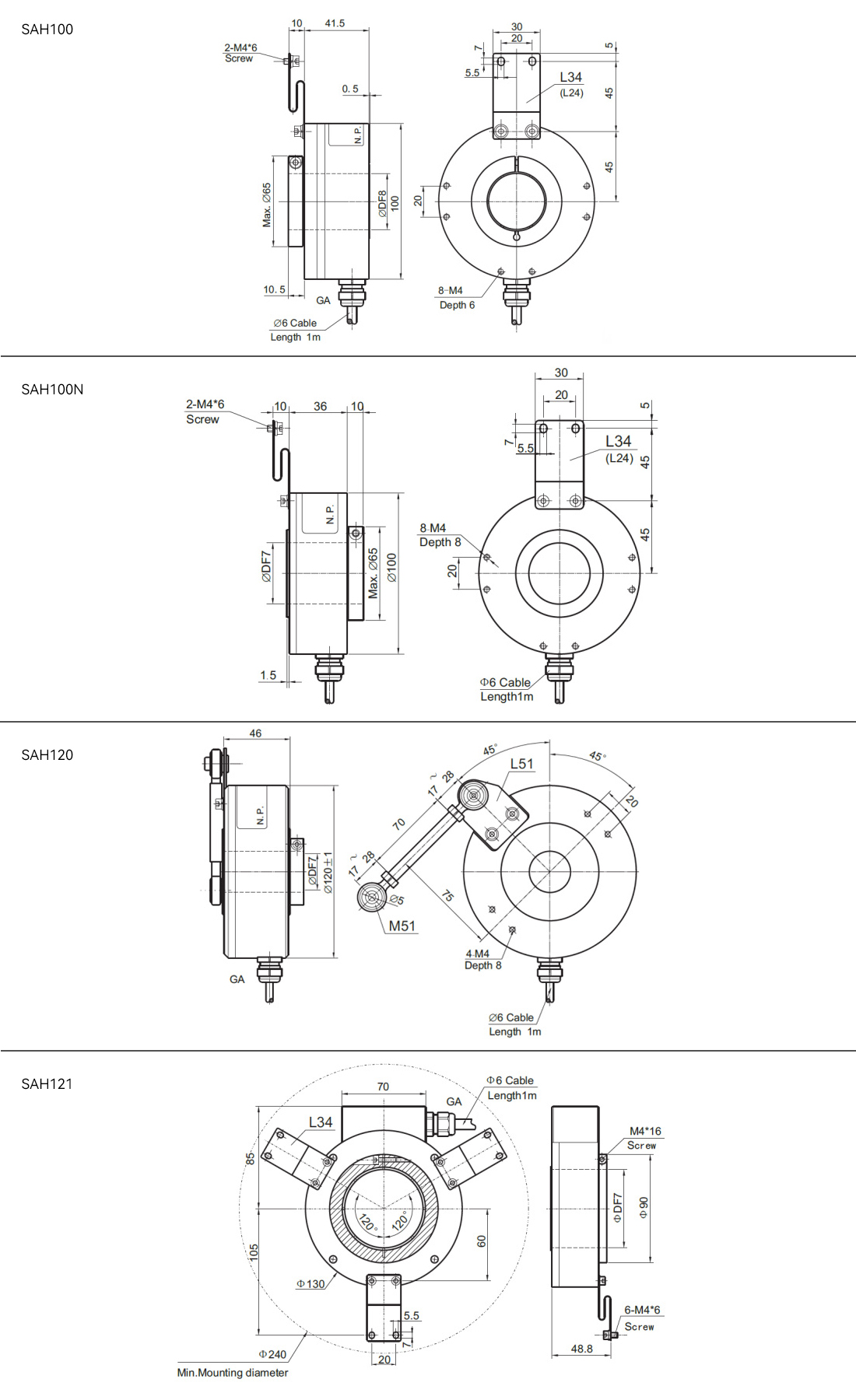

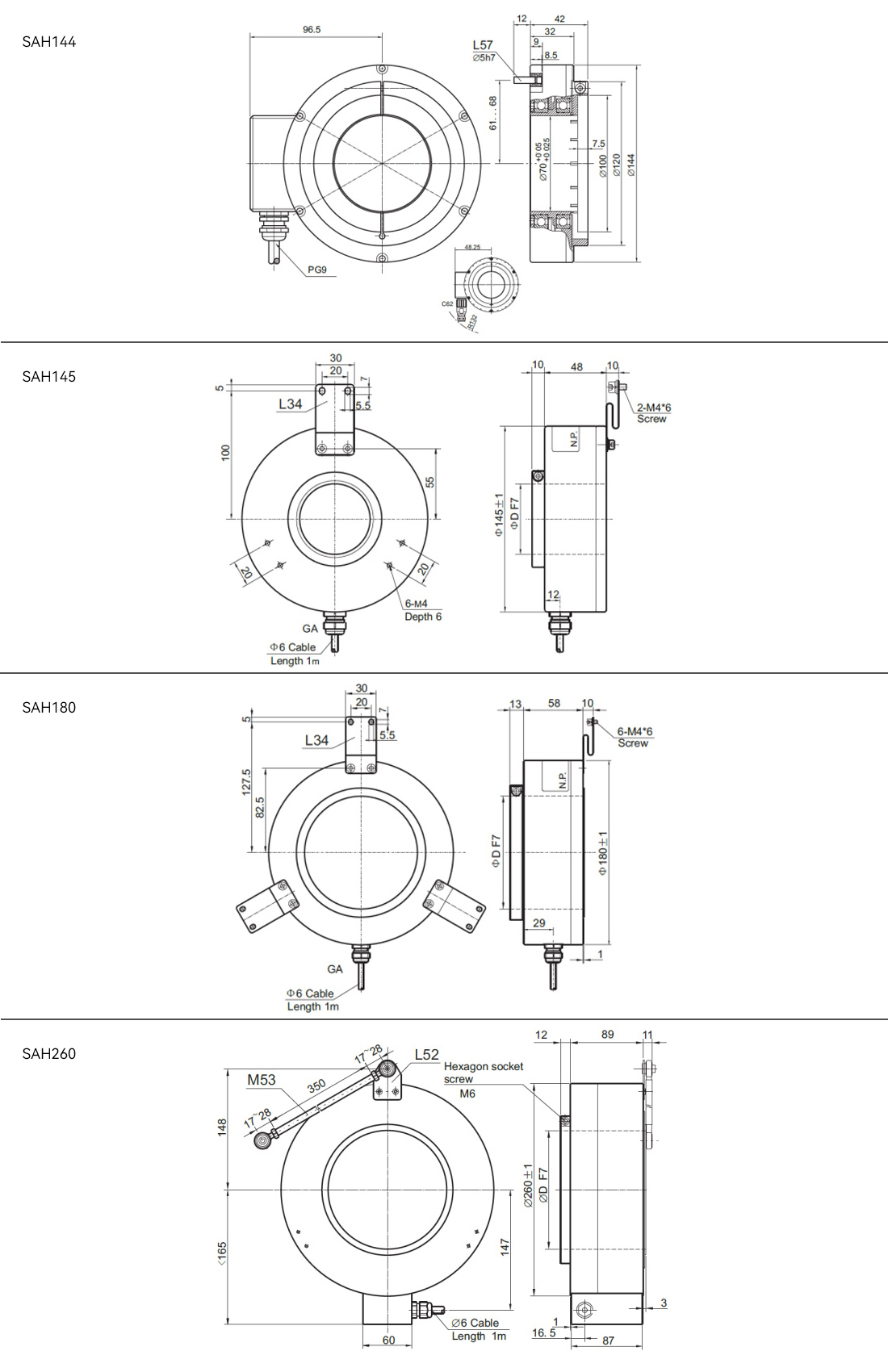

Dimension installation drawing

Large-aperture incremental encoder - Outer diameter :66mm-90mm through-hole type

Large-aperture incremental encoder - Outer diameter :100mm-120mm through-hole type

Large-aperture incremental encoder - Outer diameter :144mm-260mm through-hole type

Product Display

The maximum aperture of the large-aperture incremental encoder reaches 145mm

making it suitable for equipment with large shaft diameters

Easy to install, precise in measurement, stable and reliable in signal output

it can meet the requirements of high-precision measurement

Match different reducing rings and install spring pieces

It can flexibly match various mechanical parameters

It is applicable to various scenarios

Application Cases

The industries and projects involved include ports, lifting, shipping, mining, water conservancy, steel and metallurgy, petrochemicals, stone, energy, food processing, aerospace, automobiles, papermaking and printing, injection molding, textiles, stages, glass, packaging, military industry, elevators, machine tools, etc.

Service

1. Precautions for Using Encoders

A place where the ambient temperature must not exceed the storage temperature; A place where the relative humidity must not exceed the storage

humidity; It cannot be in places with sharp temperature changes and fogging. Places close to corrosive gases and flammable gases; Stay away from

places with a lot of dust, salt and metal powder. Stay away from places where water, oil and medicine are used; Excessive vibration and shock can be

transmitted to the main body

2. Precautions for Installing Encoders

Electrical components must not be subjected to overvoltage or other phenomena. Please conduct static electricity assessment of the setting

environment, etc. Do not allow the motor power line to approach the encoder. The FG wire of the motor and the FG wire of the mechanical device

must be reliably grounded. Since the shielded wire is not connected to the encoder body, the shielded wire must be effectively connected to the

ground at the user end

3. Precautions on Wiring

When used at the specified power supply voltage, please pay attention to the decrease in power supply voltage amplitude caused by the long wiring.

Please do not use the encoder line and other power lines in the same pipe or bundle them in parallel. Please use twisted-pair wires for the signal line

and power line of the encoder. Please do not apply excessive force to the wire harness of the encoder, as there is a risk of wire breakage

4. Regarding the warranty of the encoder

Within twelve months of purchasing the products of our company, if any malfunction occurs due to correct use in accordance with the precautions

in the user manual, warning signs, etc., free warranty will be provided.

The following situations will be charged even within the warranty period: (Freight is at your own expense)

①. Faults and damages caused by the user landing during transportation or handling or improper installation;

②. Faults of this product caused by the machine connected to it;

③. Faults and damages caused by fire, salt water, corrosive gases, abnormal voltages, and other natural disasters such as earthquakes, lightning, wind, and floods;

④. Repair, adjustment or modification without the permission of our company (the label is not present or the outer cover is removed by oneself).

⑤. Malfunctions that occur when the user does not follow the usage methods and precautions described in the user manual.

⑥. Except where there are other agreements signed with the client.