Product Description

The M5 6-Axis Mini Collaborative Robotic Arm is a compact and lightweight industrial robot designed for precision tasks in limited spaces. With a 5 kg payload capacity and ±0.03 mm repeatability, it is ideal for assembly, pick-and-place, inspection, and other repetitive operations. Its 6 degrees of freedom (DOF) enable flexible movement, while the collaborative design ensures safe operation alongside human workers. Easy to integrate into existing production lines, the M5 is suitable for automation in electronics, light manufacturing, education, and R&D environments.

Product Features

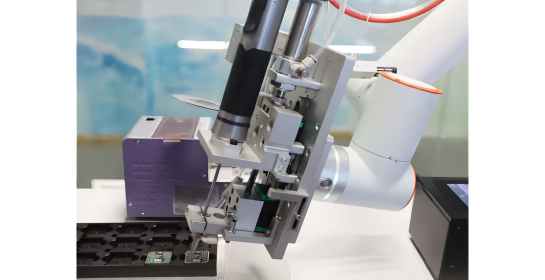

SCREW TIGHTENING ROBOT

With the end intelligent tightening device,the torque is adjustable, controllable and editable, which issuitable for

screw locking in various scenarios, and can stably, efficiently and accurately complete the production process,

greatly reducing the repetitive labor of workers, and supporting data traceability.

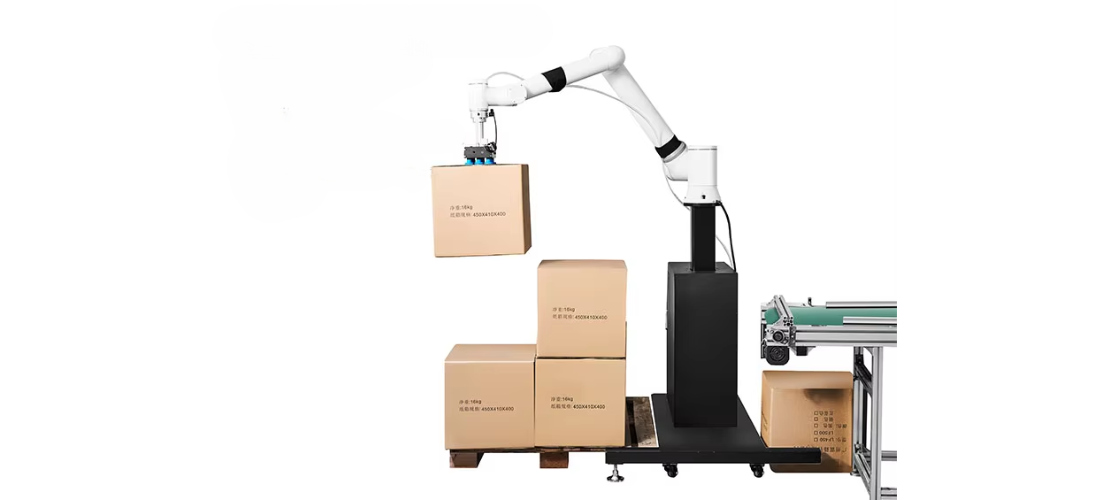

PICK AND PLACE SOLUTION

Loading and unloading robots can improve production efficiency, quality and safety, reduce laborintensity,

and provide flexibility and adaptability.Enterprises bring higher benefits and competitive advantages.

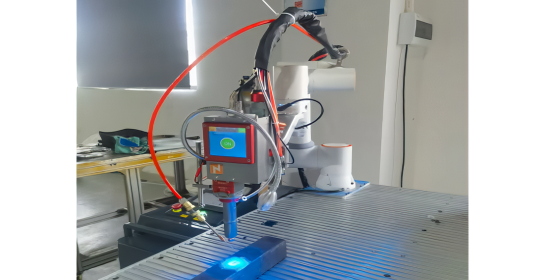

GLUE DISPENDING SOLUTION

With the end of the intelligent gluing device, fine operation, suitable for fine gluing and dispensing work in many

scenarios, can be stable, efficient and accurate to complete the gluing process, ensure the gluing effect, greatly

reduce the repetitive labor of workers, protect the health of workers.

WELDING ROBOT

Rich welding process package, with a variety of welding processes, including spot welding, segment welding.

direct welding, swing welding,Circular arc welding, multi-layer and multi-pass welding, well and intelligent

welding technology with welding wire location, weld tracking, remarkable Improve welding efficiency and

guarantee welding quality.

CONVEYOR BELT SOLUTION

Improve work safety, real-time monitoring and feedback,reduce error rates and losses,and improve productivityData recording and traceability, accurate tracking and identification.

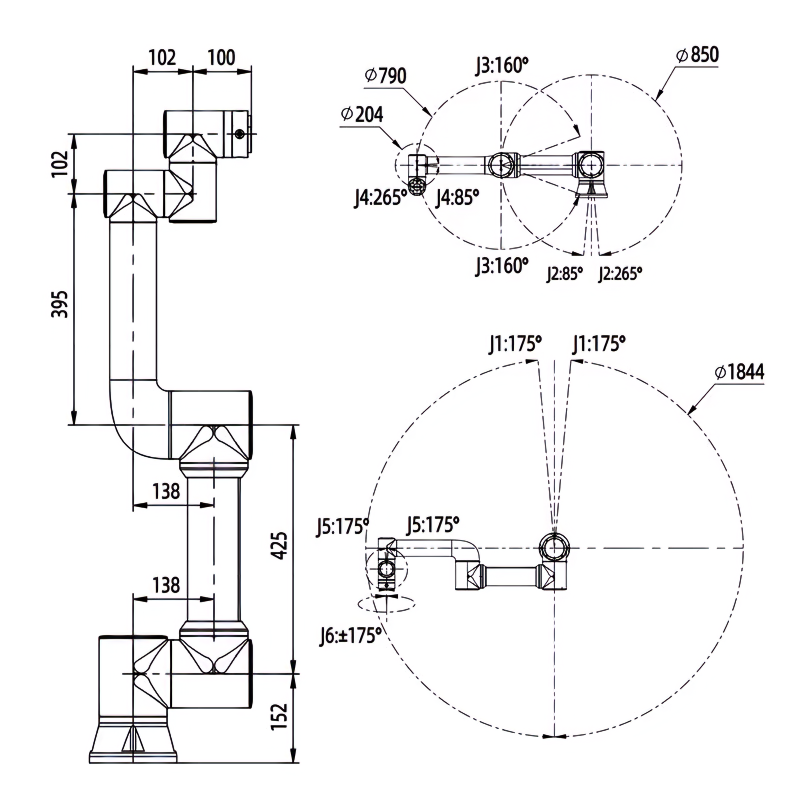

Product parameters

Parameter | Specification |

Degrees of Freedom | 6Axis (6DOF) |

Payload Capacity | 5 kg |

Maximum Reach | 922 mm |

Repeatability (Precision) | ± 0.02–0.03 mm |

Maximum Speed | Up to ~1 m/s (typical TCP speed) |

Weight of Arm | ~22 kg (approx.; lighter variants may exist) |

Power Supply | 24 V DC / ~1.5 A; also supports 110–230 V AC |

Communication Interfaces | I/O, TCP/IP, ModbusTCP/RTU, Profinet, etc. |

Human Machine Interface | 10.1″ teach pendant or mobile app-based HMI |

Safety Rating and Design | Collaborative design for humanrobot interaction; often rated up to IP54/IP66 |

Typical Applications | Pick and place, assembly, inspection, sorting tasks |

Warranty/Support | Commonly 12 months |

Service

WORKSHOP SHOW

CERTIFICATE

Order Process Flowchart

| 1. Inquiry & Requirement Submission |

| 2. Quotation & Order Confirmation |

| 3. Sample or Direct Production |

| 4. Mass Production |

| 5. Quality Check & Packing |

| 6. Shipping & After-Sales Support |

Product advantages and highlights

Compact Design

Ideal for use in confined workspaces such as desktops or small production lines.

High Payload Capacity (5 kg)

Handles medium-sized components efficiently for various industrial tasks.

High Precision (±0.03 mm)

Suitable for delicate tasks like assembly, inspection, and testing.

6 Degrees of Freedom (6-DOF)

Provides flexible motion and greater versatility in complex operations.

Collaborative Safety Design

Built to safely work alongside human operators in shared environments.

Lightweight & Easy to Deploy

Easy to transport, install, and integrate into existing workflows.

Versatile Applications

Ideal for pick-and-place, assembly, inspection, and repetitive automation tasks.