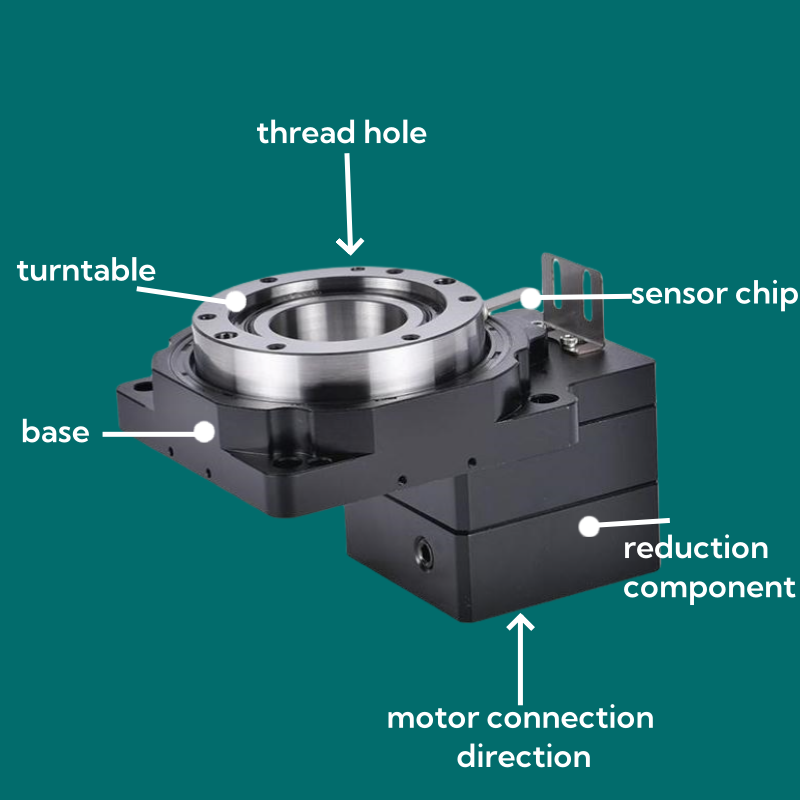

Product Description

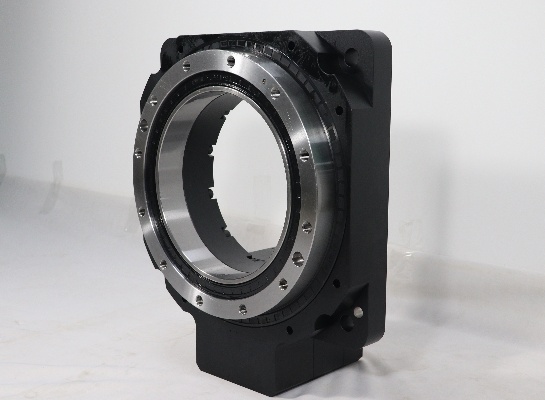

The KTN85 hollow rotary platform is a compact and lightweight high-precision rotary actuator featuring a cross roller bearing structure for superior rigidity and load capacity. Available in 5:1, 10:1, and 18:1 gear ratios, it delivers a rated torque of up to 40Nm with a maximum rotation speed of 100rpm and repeatability of ±15 arcsec. The unit supports a wide range of servo and stepper motors, making it ideal for high-precision motion applications in space-constrained environments, have strong versatility. With an IP40 protection rating and a service life of up to 20,000 hours, the KTN85 offers a reliable and durable solution for industrial automation.

In addition to horizontal installation, it can also be installed vertically, upside down or tilted

Functional Features

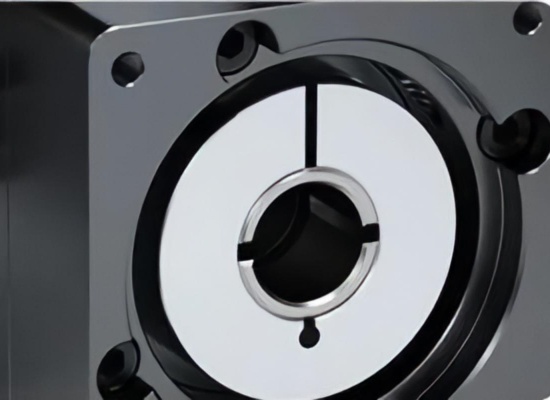

This rotary platform is designed for seamless integration with a wide range of servo and stepper motors. The hollow shaft design also supports cable routing and integration with rotating mechanisms. With IP40 protection and robust performance, the KTN85 is a dependable choice for applications requiring accurate and compact rotary actuation.

High-Precision Repeatability

±15 arcsec repeatability ensures excellent positioning accuracy in demanding motion systems.

Modular Motor Compatibility

Supports multiple gear ratios and motor flanges, allowing quick integration with popular motion control systems.

Stable Load Capacity

Rated torque of 40Nm and axial load capacity of 400N, suitable for carrying workpieces or fixtures.

Lightweight & Long-Life Design

Weighs only 1.8kg, with up to 20,000 hours of service life for low-maintenance operation.

Easy Installation

Standard flange interface enables quick integration with various motors and mounting setups.

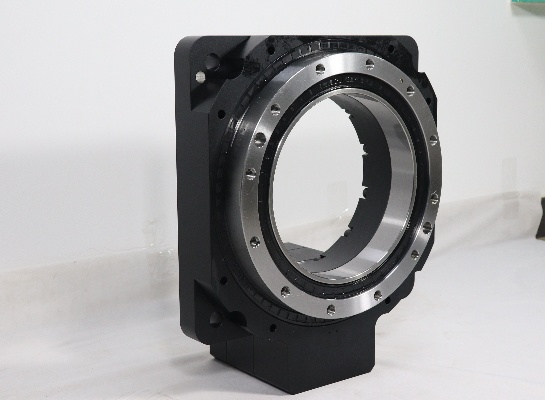

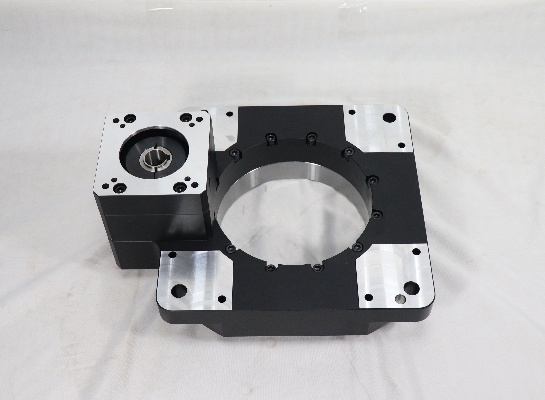

Product Display

Product parameters

Model | KTN60-5K | KTN60-10K | KTN85-5K | KTN85-10K | KTN85-18K | KTN110-5K | KTN110-10K |

Rotary platform bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing |

Reduction ratio | 1:05 | 1:10 | 1:05 | 1:10 | 1:18 | 1:05 | 1:10 |

Allowable input torque(Nm) | ≤5.2 | ≤5 | ≤40 | ≤35 | ≤20 | ≤47 | ≤35 |

Allowable platform speed(rpm) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Positional accuracy(arcsec) | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 |

Repeated positioning accuracy(arcsec) | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 |

Allowable axial load(N) | 200 | 200 | 400 | 400 | 400 | 800 | 800 |

Rotating platform flatness(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Rotating platform concentricity(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Protection level | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 |

Precision life(hrs) | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

Weight(kg) | 1.2 | 1.2 | 1.8 | 1.8 | 1.8 | 2.6 | 2.6 |

Model | KTN130-10K | KTN130-18K | KTN170-10K | KTN200-10K | KTN200-18K | KTN280-10K | KTN280-18K |

Rotary platform bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing | crossed roller bearing |

Reduction ratio | 1:10 | 1:18 | 1:10 | 1:10 | 1:18 | 1:10 | 1:10 |

Allowable input torque(Nm) | ≤55 | ≤55 | ≤72 | ≤90 | ≤90 | ≤135 | ≤135 |

Allowable platform speed(rpm) | 100 | 100 | 100 | 100 | 100 | 60 | 60 |

Positional accuracy(arcsec) | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 | ±30 |

Repeated positioning accuracy(arcsec) | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 | ±15 |

Allowable axial load(N) | 1000 | 1000 | 1000 | 2000 | 2000 | 4000 | 4000 |

Rotating platform flatness(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Rotating platform concentricity(mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 |

Protection level | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 | IP40 |

Precision life(hrs) | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 | 20000 |

Weight(kg) | 4 | 4 | 10 | 10 | 10 | 19 | 19 |

Adaptive motor | 57 stepper motor | 57 stepper motor | 86stepper motor | 86stepper motor | 86stepper motor | 130frame servo motor | 130frame servo motor |

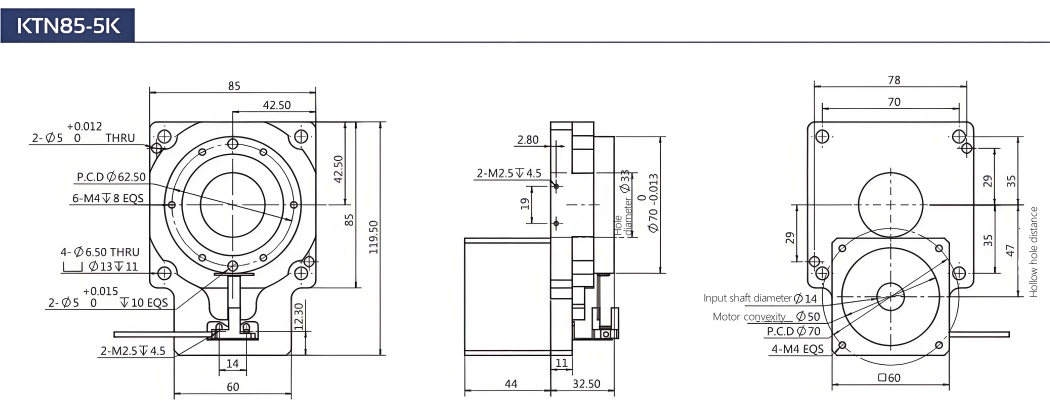

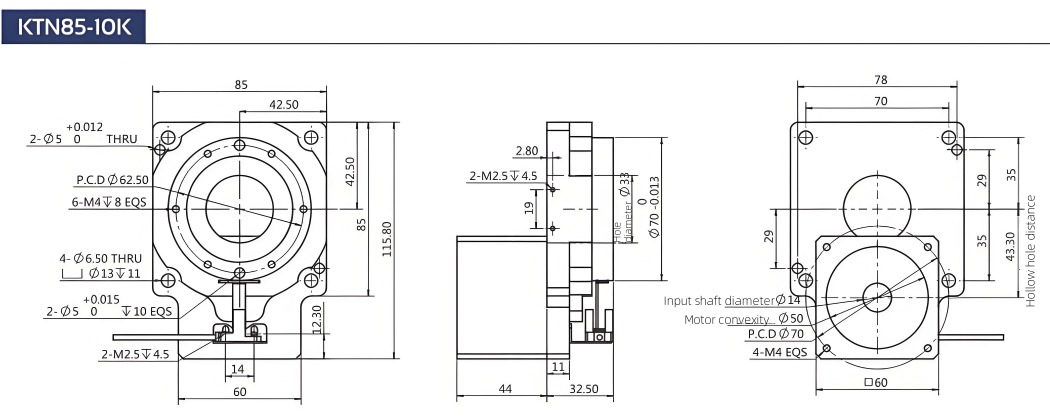

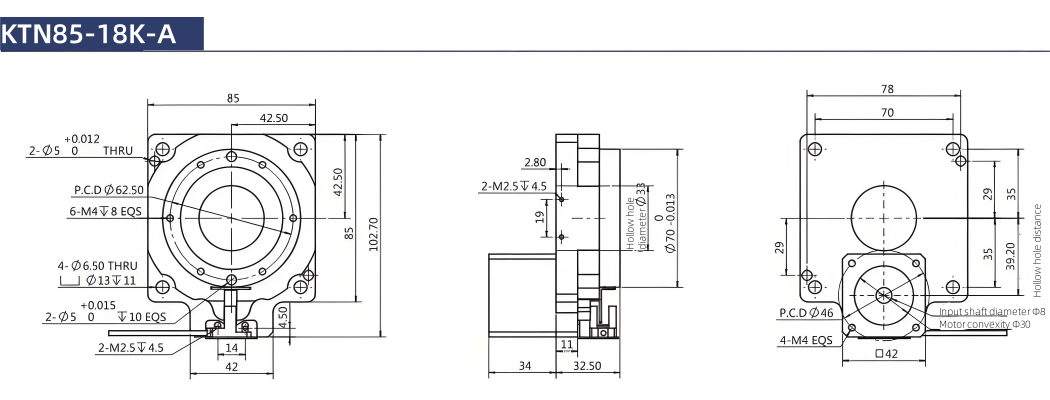

Dimensional drawing

Application Case

KTN85 is widely used in fields such as industrial automation, electronic assembly, vision inspection, medical equipment, laser processing, and precision positioning systems. Its small footprint and high precision make it ideal for rotary positioning modules, inspection platforms, turntables, dispensing or welding systems, and collaborative robot joints. It is particularly suitable for applications that demand compact size, modular design, and consistent accuracy in confined workspaces.

Product Delivery

Our Advantages

Robotics-Driven Engineering: Over 10 years of experience in motion control and robotics component design.

Precision Manufacturing: High-level machining and assembly processes ensure product consistency and performance.

Fast Delivery: Standard models in stock for rapid delivery, minimizing your project lead time.

Comprehensive Support: Technical consulting, on-site setup guidance, and remote diagnostics available.

FAQ

1.What gear ratios are available for the KTN85?

KTN85 is available in 5:1, 10:1, and 18:1 gear ratios to meet various torque and speed requirements.

2.What types of motors can be mounted on the KTN85?

The KTN85 supports a wide range of servo and stepper motors and features standardized flange interfaces for easy installation.

3.What is the repeatability of the KTN85?

The KTN85 offers a repeatability of ±15 arcsec, making it suitable for high-precision positioning and indexing applications.

4.What is the load capacity of the KTN85?

It supports a maximum torque of 40Nm and axial load of up to 400N, suitable for fixtures, rotary platforms, or light payloads.

5.What is the protection rating of the KTN85?

With an IP40 protection rating, it is suitable for clean, dry indoor automation environments.

6.What is the expected service life of the KTN85?

Under normal operating conditions, the KTN85 offers a precision service life of up to 20,000 hours, ensuring long-term reliability.

Contact Us