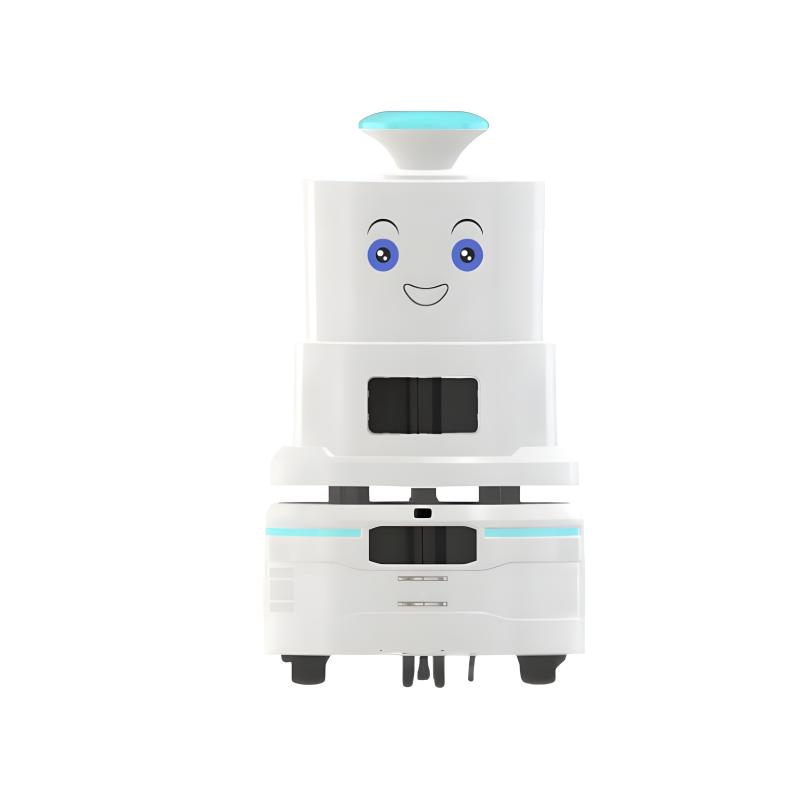

Product Description

Heavy-duty handling robots are designed for industrial scenarios. With minute-level deployment capabilities, they can be quickly put into use and start work processes efficiently. With automatic delivery functions, they can independently plan routes and accurately transport goods. They support automatic charging, without excessive human intervention, to ensure endurance and continuous operation. They can also take elevators to break through floor restrictions and expand working space. They can flexibly match production lines and easily adapt to different production rhythms and layouts, providing intelligent, convenient and efficient solutions for factory logistics and handling.

Product Features

Super strong load-bearing capacity, efficient operation

The heavy-duty handling robot has excellent load-bearing performance, with a maximum load of 600KG, which can easily handle all kinds of heavy cargo handling. Whether it is large mechanical parts or heavy raw materials, they can be transported stably to meet the stringent heavy-duty requirements in industrial scenarios.

Intelligent lifting, unmanned handling

With intelligent lifting function, it can accurately and autonomously identify shelves, automatically complete lifting and placing operations, and realize unmanned material handling throughout the entire process. Reduce manual intervention and reduce labor costs, while improving the accuracy and stability of handling, providing strong support for automated production.

Ultra-fast charging, long-lasting battery life

The charging efficiency is amazing, and it can be fully charged in only 1.1 hours, quickly restoring full power. With strong battery life, it can work continuously for several hours, effectively reducing downtime waiting time, ensuring efficient operation of production logistics links, and improving production efficiency for enterprises.

Intelligent scheduling, system collaboration

Supports RCS multi-machine scheduling, which can realize efficient collaborative operation of multiple robots, reasonably allocate tasks, avoid route conflicts, and improve overall handling efficiency. It can also be quickly connected with mainstream production management systems such as MES, ERP, WMS, etc., and seamlessly receive task instructions issued by the system, making production logistics management more intelligent, convenient and orderly.

Product parameters

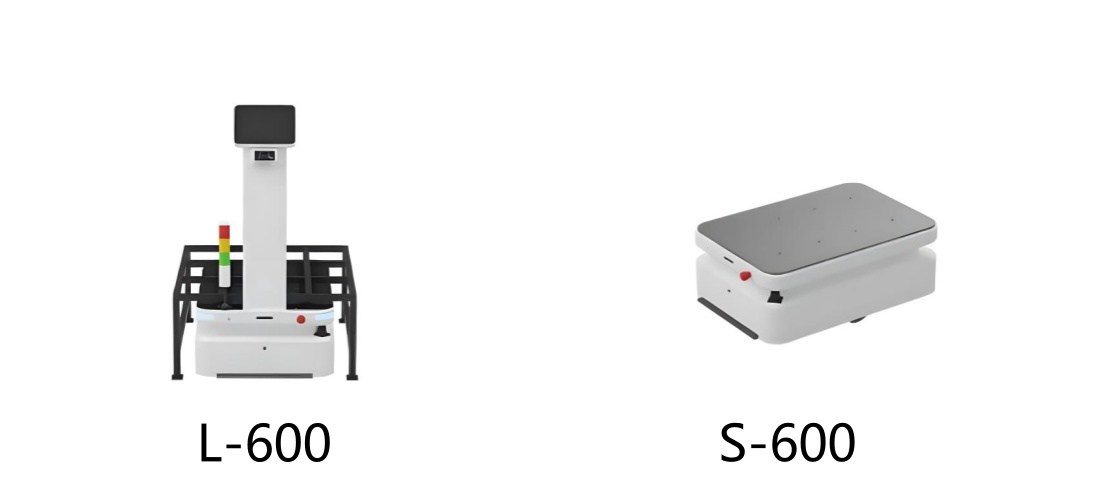

Project | L-600 | S-600 |

Device size (mm) | 950×650×1240 | 950×650×365 |

Maximum load capacity (kg) | 600 | 300 |

Unladen vehicle weight (kg) | 100 | 90 |

Load area (mm) | 940×810 | 940×810 |

Minimum pass width | 80cm | 80cm |

Maximum speed | 1.2 m/s | 1.2 m/s |

Navigation method | Free navigation / track navigation / hybrid navigation / follow | |

Positioning accuracy | 10 mm | |

Network | 4G / wifi | |

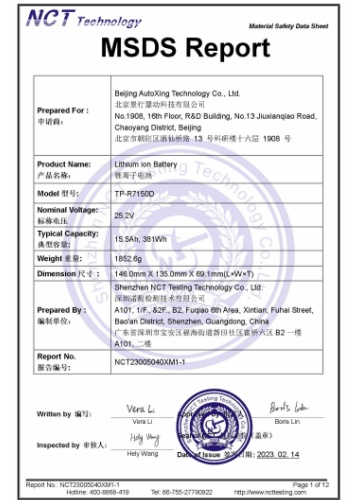

Battery | Battery life 8 hours, charging 1.1 hours | |

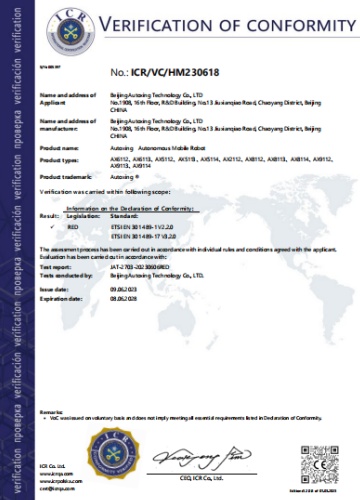

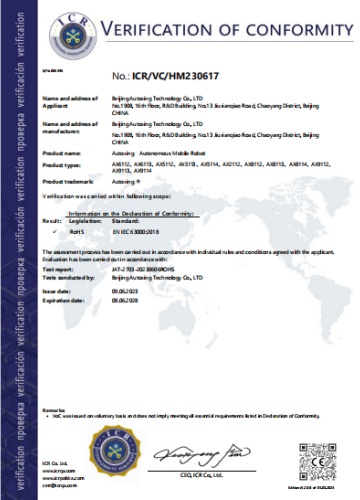

Certification | CE / FCC / KC / NCC / EMC | |

Extended peripherals | Elevator, automatic door, notification light and speaker, pager, follow bracelet, roller, box, shelf | |

Product Certificate