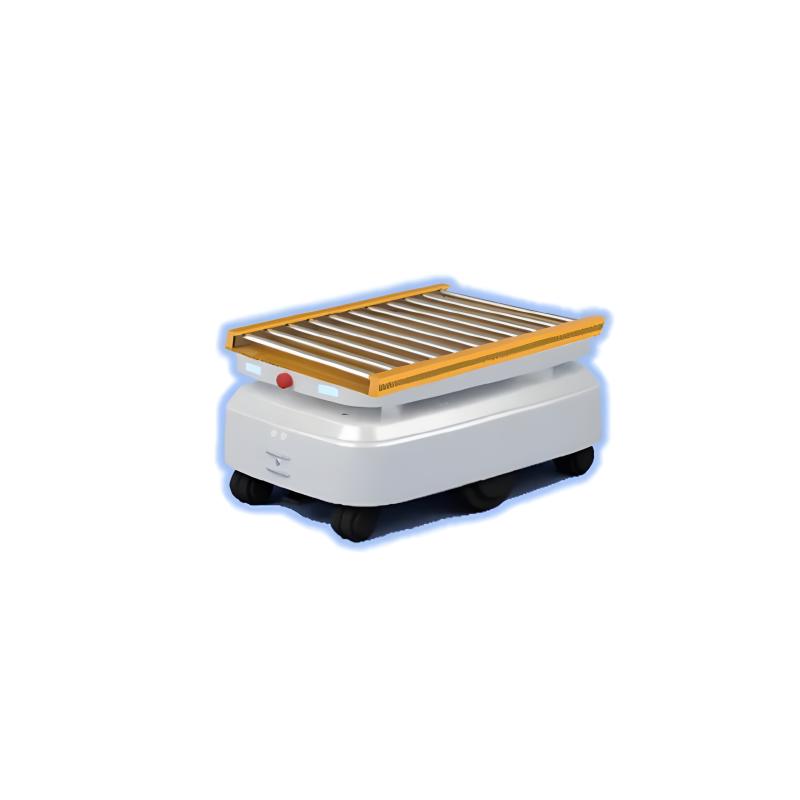

Product Description

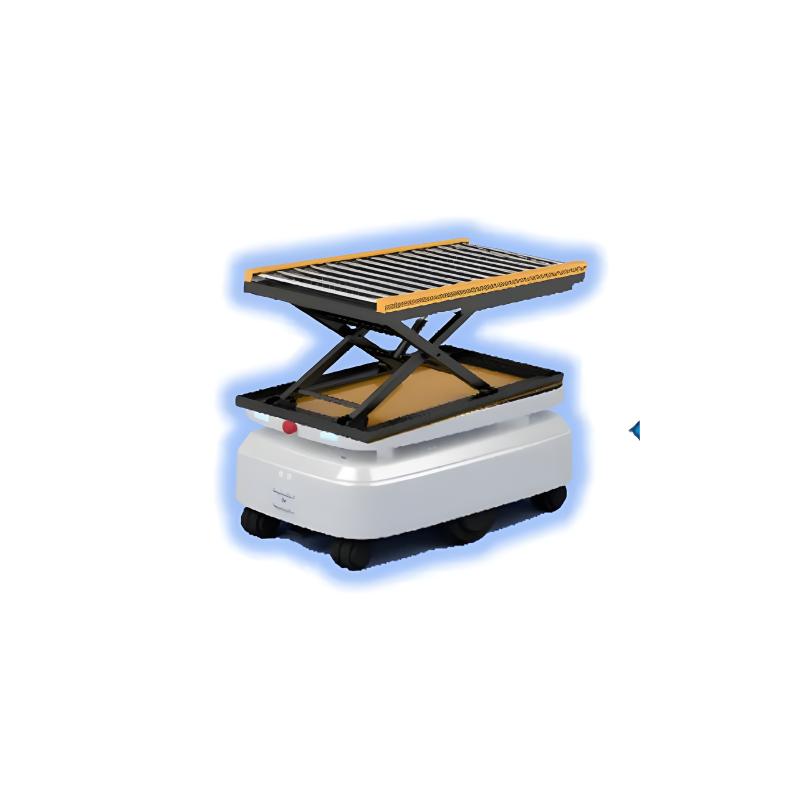

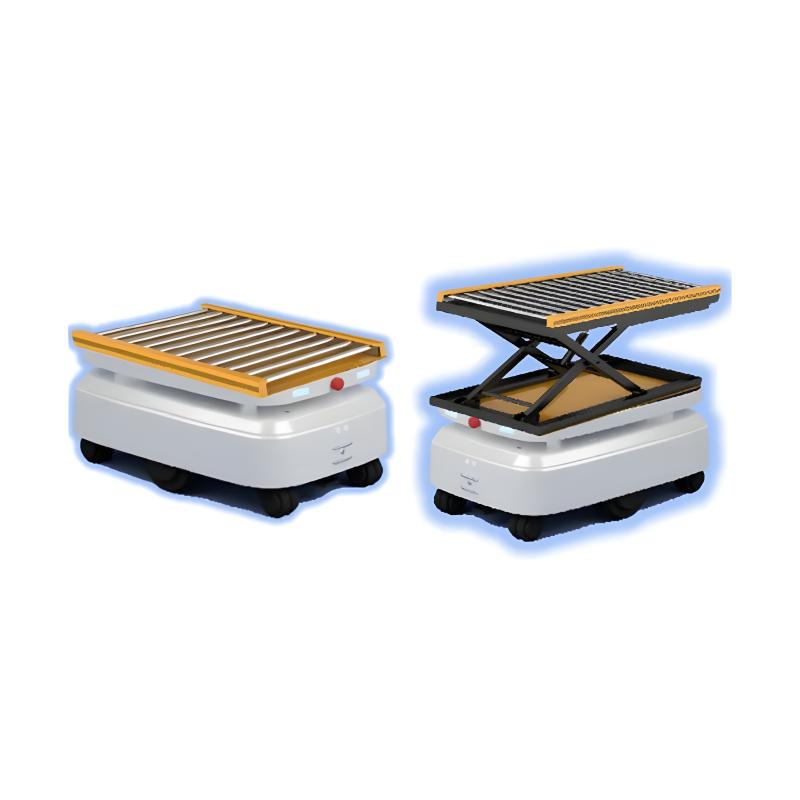

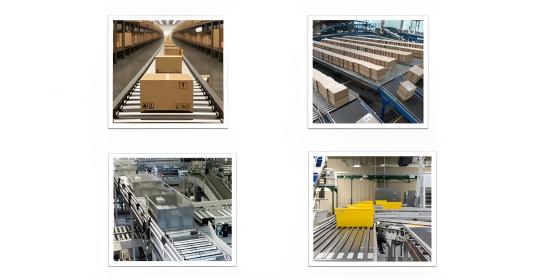

This roller transport robot is a powerful assistant for industrial automation logistics. It is equipped with an advanced SLAM laser navigation system, which can accurately locate, autonomously plan routes, and flexibly shuttle in complex working environments. The roller transport technology can efficiently and smoothly transport various types of goods, such as boxes and pallets. It has the function of automatic material detection, and monitors the material status in real time through the photoelectric sensor to prevent material loss and jamming. It supports forward/lateral roller docking, with high docking accuracy and simple and smooth loading and unloading process. It is widely used in logistics warehousing, production line transportation, freight distribution center, electronic manufacturing and other scenarios. It can realize the automatic handling of goods from the starting point to the target point, greatly improve transportation efficiency, reduce labor costs, and inject intelligent power into the production and logistics links of enterprises.

Product Features

The upper roller assembly is driven to connect with AMR to transfer goods

Connect with production line to connect materials with production line

Take into account different carriers such as material boxes, trays, and pallets

Support cross-floor transportation and connection

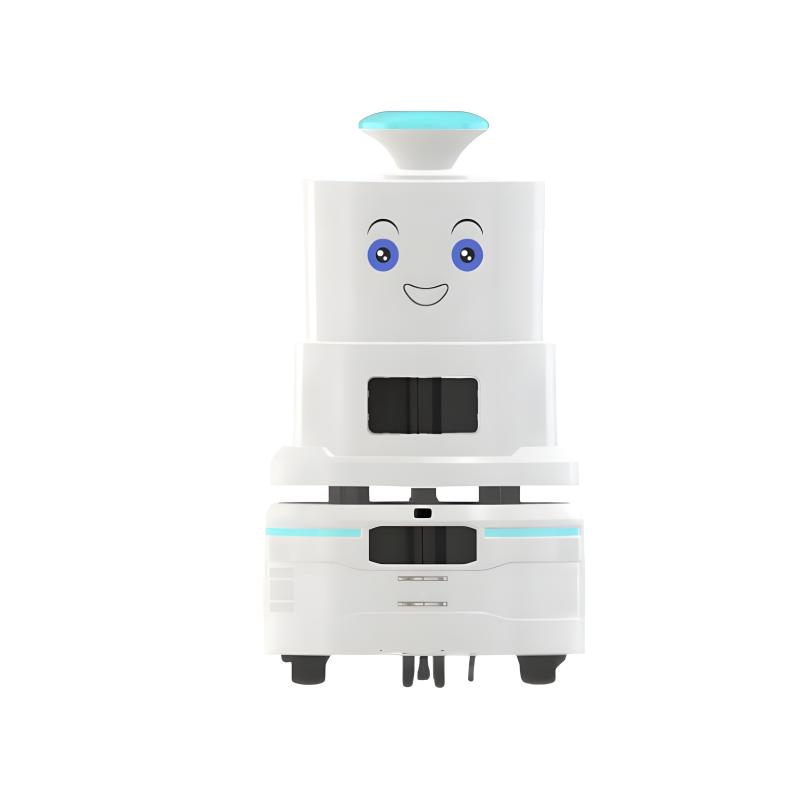

Customized development of composite robots

(The specific form needs to be determined by the production line height and the shape of the goods)

The roller mechanism uses multiple sensors to achieve real-time monitoring of the position of the goods

Supports docking with the factory assembly line system

Supports the task system customization of assembly lines in various industries

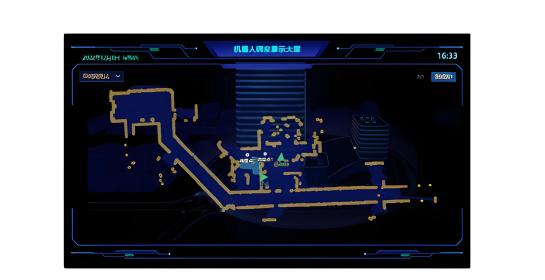

Robotic Scheduling and Control System (RCS)

Intelligently adjust the robot's queuing strategy to shorten the task waiting time;

Analyze and predict the time when the workbench generates tasks

Schedule idle mobile robots to wait at the task point in advance to improve overall logistics efficiency;

Reasonably control the handling order and timing of the shelves to achieve task load balance on each workbench.

Robot local dispatch/support external device interconnection

Multi-machine collaborative work can be achieved without setting up RCS, realizing common scene functions such as multi-machine encounter obstacle avoidance, narrow road dispatch, elevator dispatch, etc. Rapid deployment and flexible docking of production lines.

Gate machines, automatic doors, rolling doors, 99% of passenger elevators and freight elevators on the market, support for multi-machine elevator dispatch, arrival notification lights, notification speakers

The roller composite robot can meet the needs of internal logistics handling. It can flexibly integrate different functional modules according to the process flow of various industries. It can be connected with automated assembly lines and roller conveyor lines to achieve flexible material handling and connection between assembly lines. It is suitable for the field of factory logistics automation and transportation, and supports the transportation of multiple types of materials, such as pallet materials, carton materials, etc., which significantly improves the efficiency of workshop logistics.

Product parameters

Item | Parameters |

Size | 713*471mm |

Transfer method | Roller (customizable) |

Self weight (kg) | 60 |

Load (kg) | 100 |

Stop angle accuracy (°) | 士1 |

Minimum passing width (cm) | 70 |

Rated operating time (h) | 8 |

Roller height adjustable (mm) | 550-1000 |

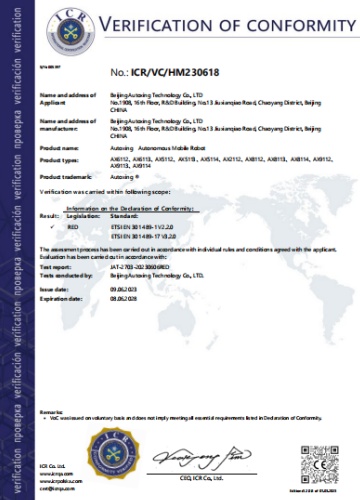

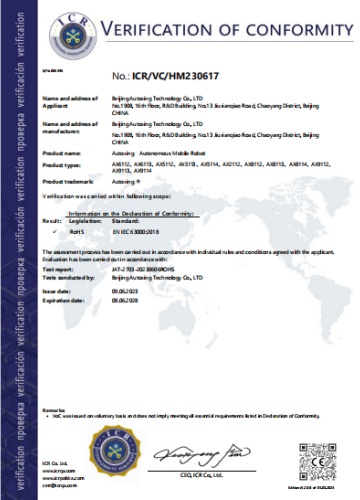

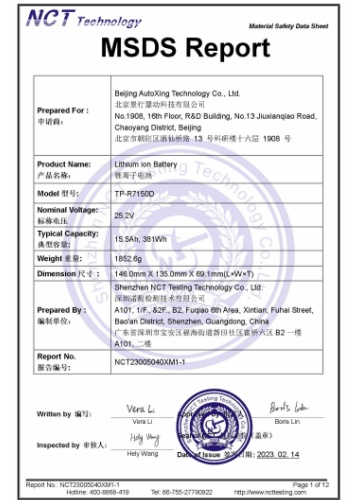

Product Certificate