Product Description

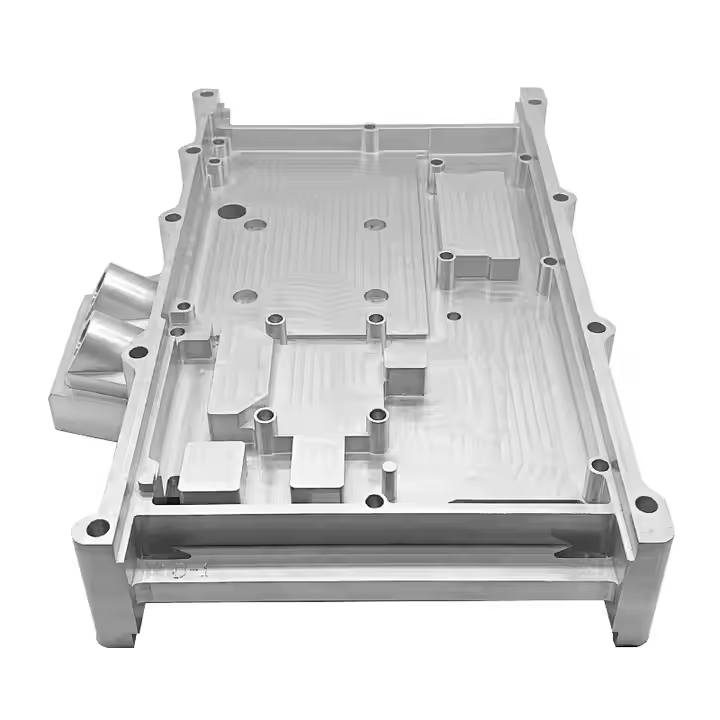

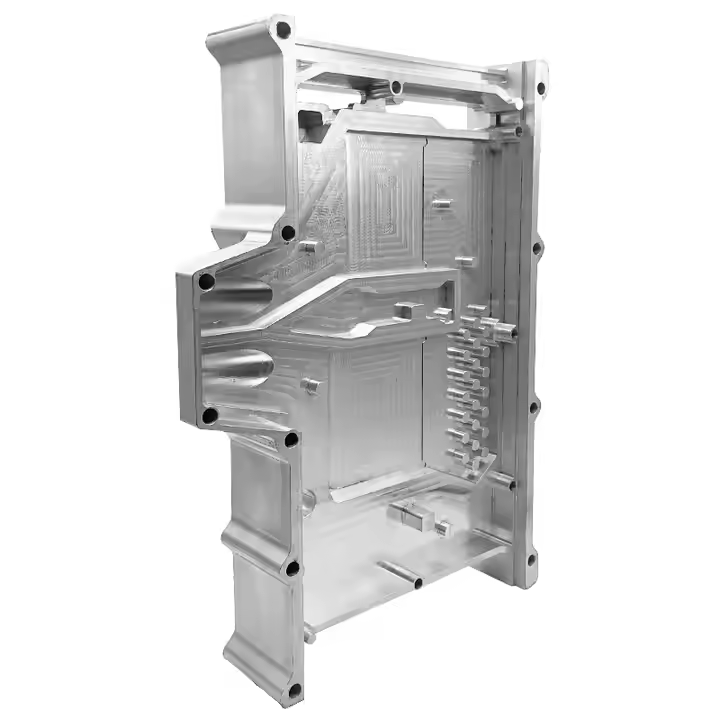

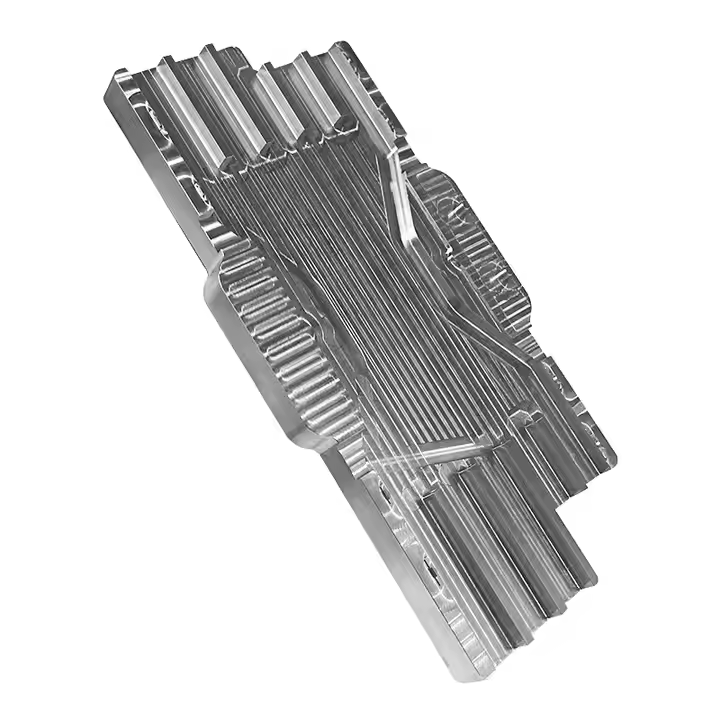

Stamping engine parts involves using high-pressure dies to shape metal sheets into precise components for automotive engines. This process ensures high-speed, mass production with consistent quality and tight tolerances. Stamped parts, such as engine brackets, covers, and structural components, are critical for performance and reliability. The method is cost-effective, offering both material efficiency and quick turnaround times. Quality control during stamping, including proper die design and material selection, is essential to avoid defects and ensure durability. Advanced techniques, such as progressive stamping, enable more complex part designs while maintaining production efficiency.

Product parameters

| List | Details |

|---|---|

| Brand Name | CNC Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Micro Machining | Micro Machining |

| MOQ | Small orders accepted |

| Cost control | Most efficient production process design |

| QC control | 100% inspection on critical dimensions |

| Mangement | Skilled workers and rich experiencd staff |

Custom Process

1. send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Aluminum Sheet

Metal Sheet

Brass Sheet

Copper Sheet

Quality Control

Metal stamping is more than just a step in the manufacturing process; it’s the cornerstone of production, ensuring that final products meet rigorous standards and customer expectations. At Adept Corporation, we recognize the vital role quality control plays in upholding our reputation as industry leaders. This article delves into the key aspects of quality control in metal stamping, highlighting how Adept consistently ensures excellence in every component we produce.

Processing capability

The stamping process for engine parts is an essential technique used to shape metal sheets into specific forms through the application of pressure. It enables high-efficiency, large-scale production with uniformity and precision, making it especially suitable for automotive and engine components. Factors such as material choice, die configuration, and operational settings (like temperature and speed) play a significant role in the quality of the stamped parts. Ensuring the correct amount of lubrication and controlling the stamping force are crucial to avoid defects like wrinkles, fractures, or warping.

Additional processes

This manufacturing method offers several benefits, including reduced production costs, quick cycle times, and the ability to produce intricate designs. However, it requires close oversight to ensure the components meet strict specifications. Techniques like progressive and transfer stamping allow for even more complex shapes and higher production rates. Overall, stamping is a critical process for producing engine parts, providing both accuracy and durability. As technology advances, ongoing improvements in automation and quality control are enhancing the efficiency and scope of stamping operations.