Product Description

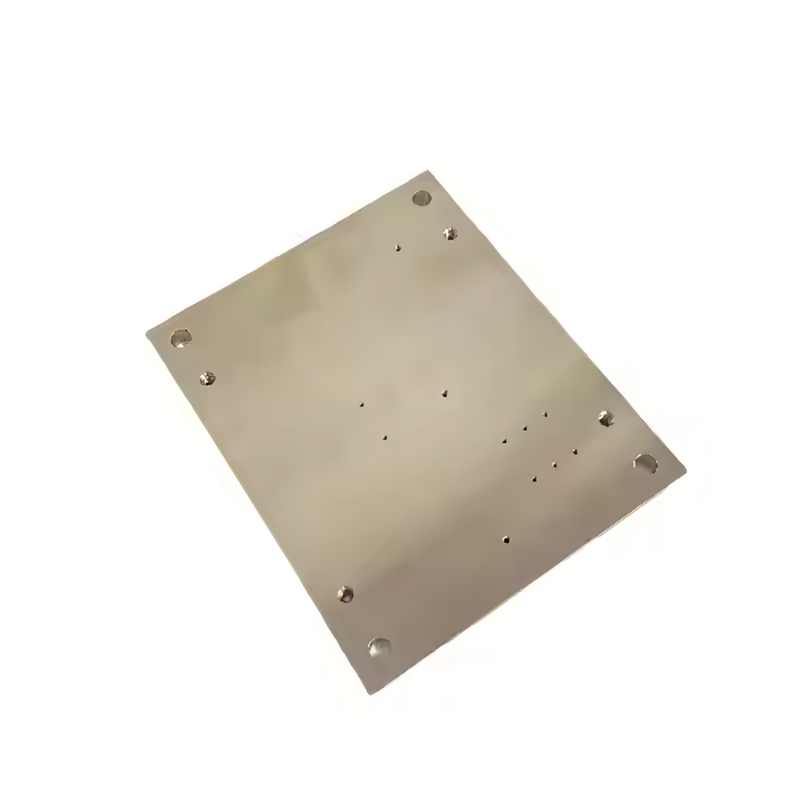

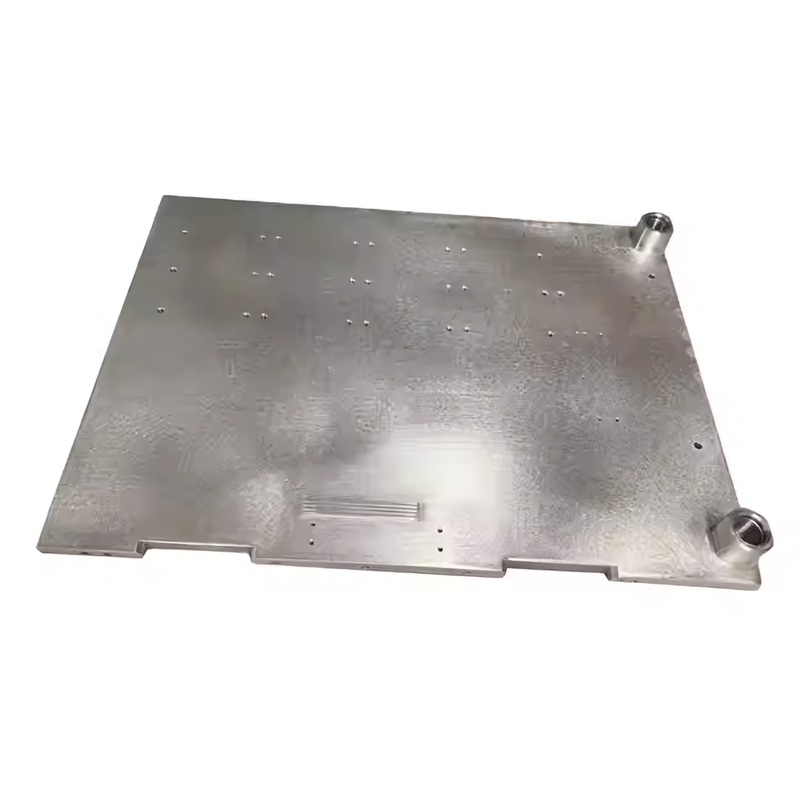

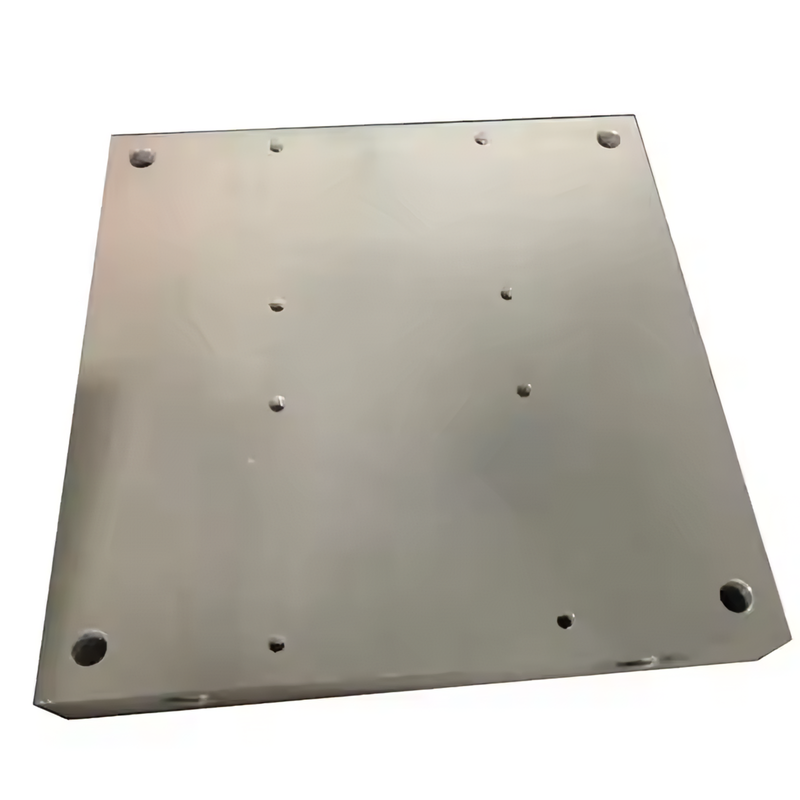

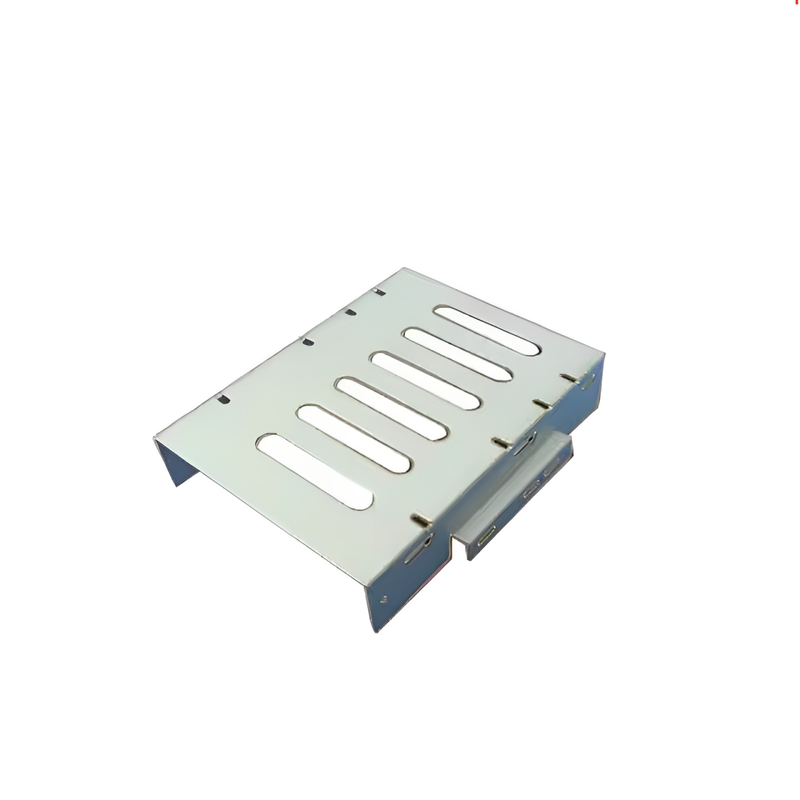

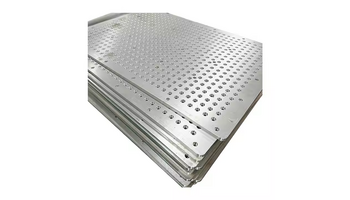

Sheet Metal Part Stamping: Precision-crafted, high-quality stamped metal parts designed for strength and durability. Ideal for automotive, electronics, and industrial applications, offering reliable performance and customizable to meet specific technical requirements

Product parameters

| Material | Aluminum,Stainless Steel,Iron |

| Dimension | Customized |

| Process | Sheet Metal,Laser Cutting,Bending,Drilling,Riveting,Welding,Polishing,Surface Treatment,Quality inspection,Packing |

| Surface Treatment | Anodizing,powder coating, sand blasting, plating, polishing, brushing, etc. |

| Application | Mechanical Equipment,Electrical Appliance,Automobile Parts,Audio-video Equipment,Robotic Industry,Communications Equipment,etc |

| Service | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format | CAD / CAM / CAE, PDF |

| Testing equipment | Vernier Calipers,Angle Ruler,Micrometer,Altimeter,etc |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

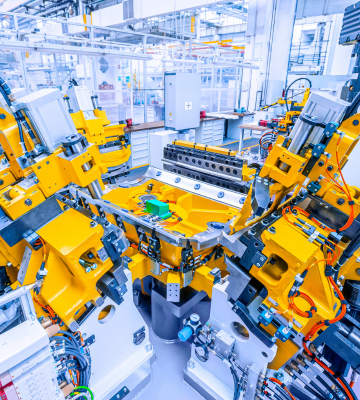

Industrial Machinery

- Reason: Parts in industrial machinery must be resistant to wear and tear and impact.

- Advantage: Stamped metal parts are strong and durable, making them suitable for heavy-duty industrial use.

Electronics

- Reason: Metal components in electronics need to be highly accurate and durable for reliable performance.

- Advantage: Stamped metal parts provide precision and durability, ideal for use in devices that experience movement or long-term use.

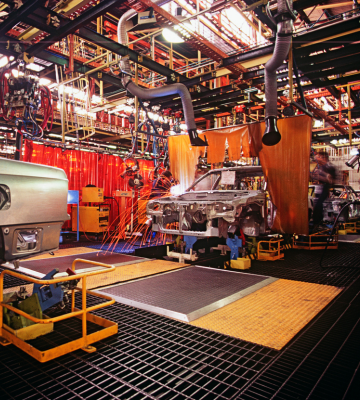

Automobiles

- Reason: Stamped metal parts such as car doors and seat frames require high strength and durability to withstand impacts and vibrations in harsh environments.

- Advantage: The stamping process produces precise and durable parts, which is crucial in the automotive industry.

Material

Aluminum Alloy

Iron

Stainless Steel

Quality Control

Quality control in sheet metal part stamping ensures parts meet specifications through material inspection, tooling checks, and dimensional accuracy using precision tools. Visual inspections detect surface defects, while mechanical tests verify strength. In-process monitoring tracks variables to prevent defects, and final inspections confirm parts meet all requirements before delivery. This ensures high-quality, reliable parts

Processing capability

Processing capability of sheet metal part stamping includes the ability to handle various material types, thicknesses, and complex shapes with high precision. It supports high-volume production, quick turnaround times, and can produce parts with tight tolerances, ensuring consistent quality and durability. The process is versatile for a range of applications, from automotive to electronics

Additional processes

Additional processes for sheet metal part stamping include deburring, welding, painting, plating, and assembly. Deburring removes sharp edges, while welding may be used to join parts. Painting and plating enhance corrosion resistance and aesthetics, and assembly ensures the final product is ready for use. These processes help improve the functionality, durability, and appearance of stamped parts, ensuring they meet precise customer specifications