คำอธิบายผลิตภัณฑ์

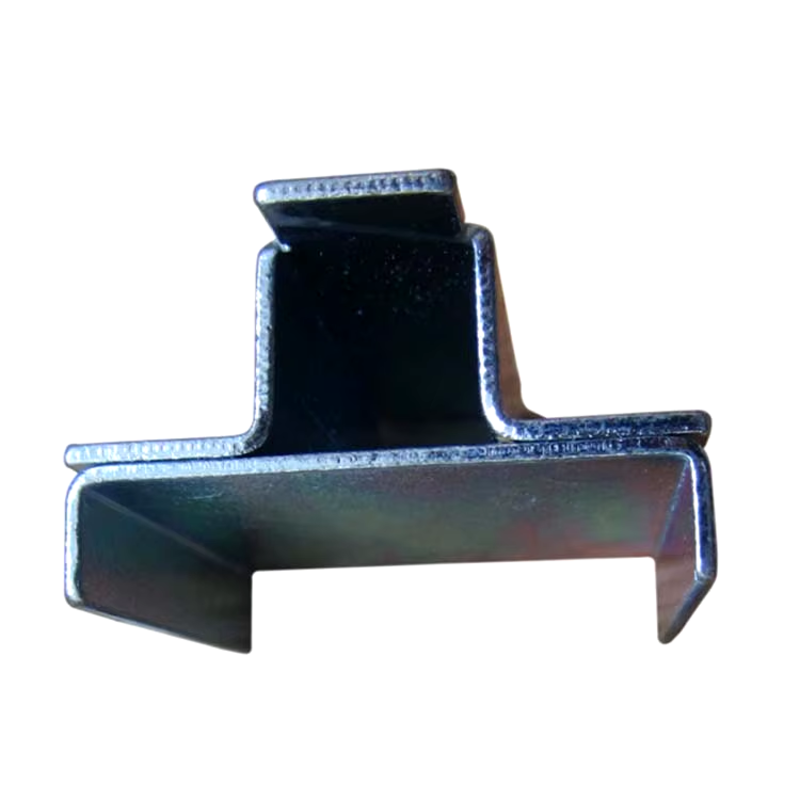

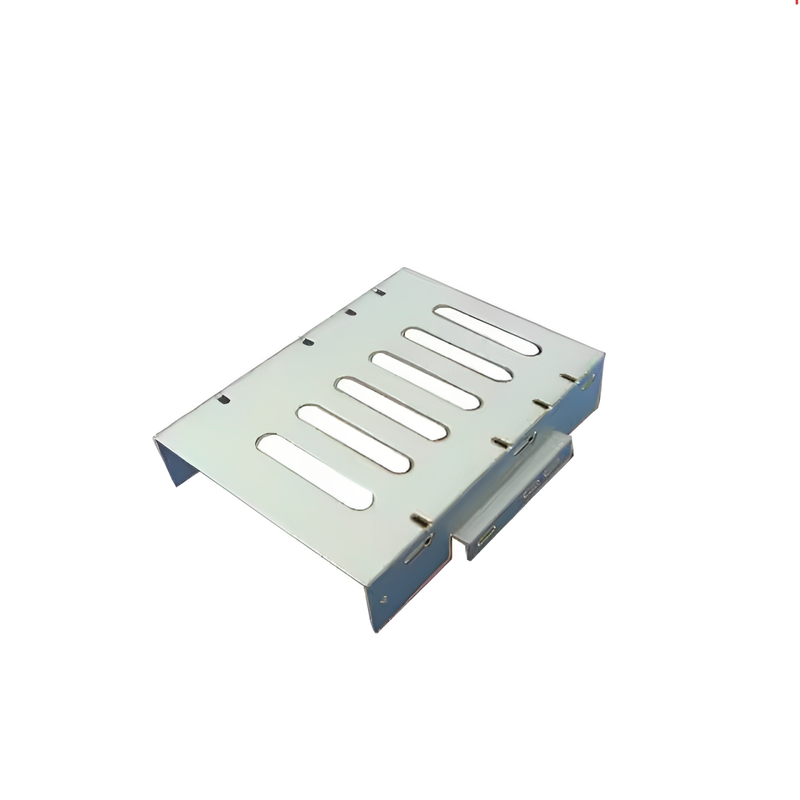

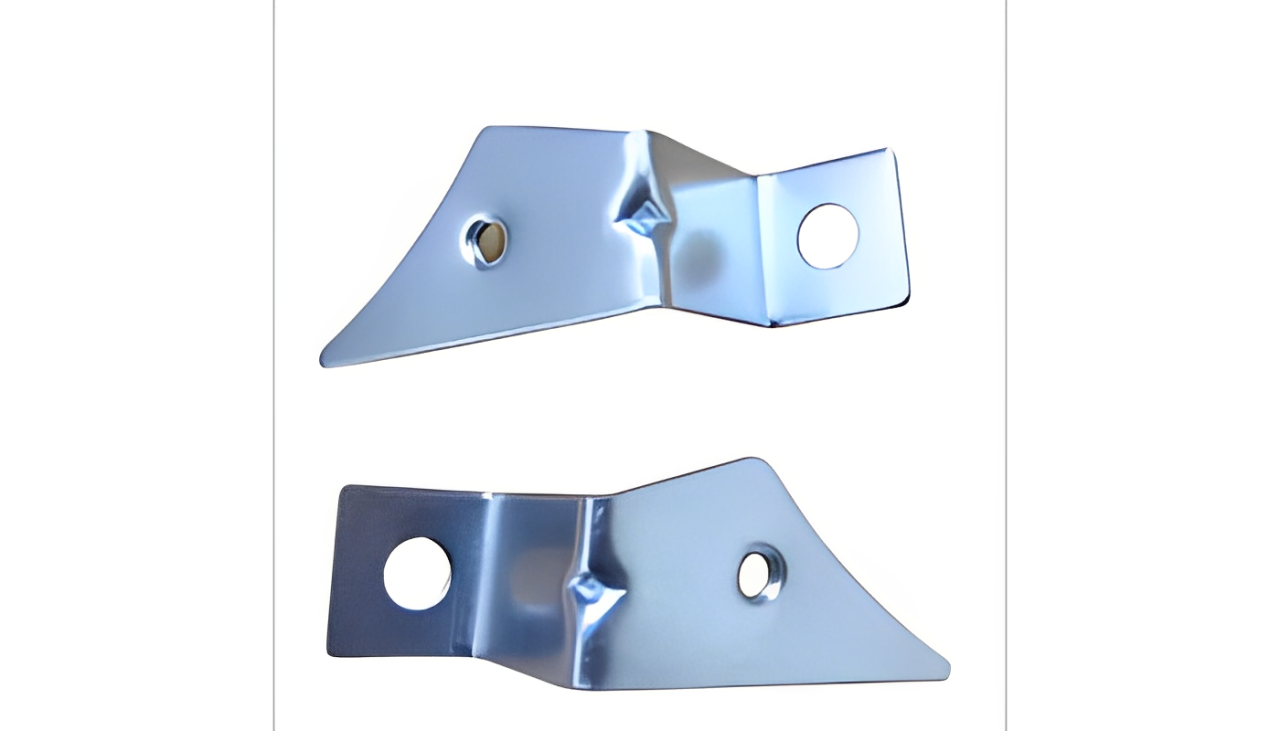

แม่พิมพ์การตีขึ้นรูปสำหรับชิ้นส่วนตัวถังรถยนต์ของเราได้รับการออกแบบเพื่อผลิตชิ้นส่วนโลหะที่มีความแม่นยำสูงและทนทานสำหรับอุตสาหกรรมยานยนต์ ออกแบบมาเพื่อรองรับรูปทรงที่ซับซ้อนและการผลิตในปริมาณมาก แม่พิมพ์เหล่านี้ช่วยให้มั่นใจในความสม่ำเสมอและความแม่นยำในการผลิตชิ้นส่วนตัวถังรถยนต์ เช่น ประตู, แผงข้าง, และฝากระโปรง ทำจากวัสดุคุณภาพสูง แม่พิมพ์การตีขึ้นรูปของเรามอบประสิทธิภาพที่ยาวนาน ช่วยให้การผลิตมีประสิทธิภาพพร้อมทั้งตอบสนองมาตรฐานที่เข้มงวดของความปลอดภัยและการออกแบบในอุตสาหกรรมยานยนต์

พารามิเตอร์ผลิตภัณฑ์

| ขนาด | ตามความต้องการของลูกค้า |

| ชิ้นงานตัวอย่าง | ตัวอย่างฟรี |

| ขั้นต่ำในการสั่งซื้อ | 100 ชิ้น |

| เวลาการจัดส่ง | 7-20 วัน |

กระบวนการที่กำหนดเอง

1. ส่งคำถามหรือการสอบถาม

2. ส่งแบบหรือ Drawing

3. ใบเสนอราคา

4. การยืนยันจากลูกค้า

5. สั่งซื้อและชำระเงิน

6. เริ่มทำการผลิต

7. ทดสอบก่อนบรรจุภัณฑ์

8. การจัดส่งและการยืนยัน

ประเภทกระบวนการ

ประตูรถยนต์

เหตุผล: ประตูรถยนต์ต้องการความแข็งแรงและความทนทานเพื่อปกป้องผู้โดยสารในกรณีที่เกิดอุบัติเหตุ กระบวนการแม่พิมพ์การตีขึ้นรูปช่วยให้ได้ชิ้นส่วนที่มีความแม่นยำและรูปทรงที่พอดีกับตัวถังรถยนต์

ฝากระโปรงหน้าและฝากระโปรงท้าย

เหตุผล: ฝากระโปรงหน้าและฝากระโปรงท้ายต้องการการขึ้นรูปที่แม่นยำเพื่อให้สอดคล้องกับการออกแบบของรถยนต์และเพื่อปกป้องเครื่องยนต์และชิ้นส่วนภายในได้อย่างมีประสิทธิภาพ กระบวนการแม่พิมพ์การตีขึ้นรูปช่วยให้ได้รูปทรงที่ต้องการและความทนทาน

แผงข้างรถยนต์ (Fenders)

เหตุผล: แผงข้างรถยนต์ต้องทนทานเพื่อรองรับสภาพแวดล้อมที่รุนแรงและต้องพอดีกับชิ้นส่วนรถยนต์อื่นๆ กระบวนการแม่พิมพ์การตีขึ้นรูปช่วยผลิตชิ้นส่วนที่ตรงกับการออกแบบและมีความแข็งแรงพอที่จะใช้งานภายนอกได้

วัสดุ

โลหะผสมอลูมิเนียม

โลหะ

สแตนเลส

การควบคุมคุณภาพ

การควบคุมคุณภาพสำหรับแม่พิมพ์การตีขึ้นรูปชิ้นส่วนตัวถังรถยนต์ทำให้มั่นใจได้ว่าชิ้นส่วนแต่ละชิ้นตรงตามมาตรฐานอุตสาหกรรมยานยนต์ที่เข้มงวดในด้านความแม่นยำ ความทนทาน และความปลอดภัย กระบวนการนี้รวมถึงการตรวจสอบวัสดุ การตรวจสอบความแม่นยำของเครื่องมือ และการยืนยันขนาดเพื่อป้องกันข้อบกพร่อง การตรวจสอบอย่างต่อเนื่องและการตรวจสอบขั้นสุดท้ายยืนยันว่าแต่ละแม่พิมพ์ผลิตชิ้นส่วนที่สม่ำเสมอและมีคุณภาพสูง ซึ่งตรงตามข้อกำหนดการออกแบบและความปลอดภัยอย่างเคร่งครัด

ความสามารถในการประมวลผล

ความสามารถในการประมวลผลของแม่พิมพ์การตีขึ้นรูปชิ้นส่วนตัวถังรถยนต์ประกอบด้วยการจัดการกับวัสดุที่มีความแข็งแรงสูง การผลิตรูปทรงที่ซับซ้อน และการบรรลุความแม่นยำที่แคบ ซึ่งเป็นสิ่งจำเป็นสำหรับการใช้งานในอุตสาหกรรมยานยนต์ แม่พิมพ์เหล่านี้รองรับการผลิตในปริมาณมากด้วยความแม่นยำที่สม่ำเสมอ ช่วยให้สามารถสร้างชิ้นส่วนที่ทนทาน เช่น ประตู แผงข้าง และเสาโครงสร้างที่ตรงตามมาตรฐานอุตสาหกรรมที่เข้มงวด

กระบวนการอื่น ๆ

กระบวนการเพิ่มเติมสำหรับแม่พิมพ์การตีขึ้นรูปชิ้นส่วนตัวถังรถยนต์ประกอบด้วยการอบชุบเพื่อเพิ่มความทนทาน การเคลือบเพื่อป้องกันการกัดกร่อน และการขัดเงาเพื่อให้ผิวเรียบและปราศจากข้อบกพร่อง กระบวนการเหล่านี้ช่วยยืดอายุการใช้งานและปรับปรุงคุณภาพของชิ้นส่วนที่ตีขึ้นรูป ทำให้มั่นใจได้ว่าชิ้นส่วนเหล่านั้นตรงตามมาตรฐานสูงที่ต้องการสำหรับการผลิตยานยนต์