Product Description

Sheet metal fabrication transforms flat metal sheets into custom parts through cutting, bending, punching, and welding. It is widely used in industries like automotive, aerospace, and construction to create precise, durable components from materials like stainless steel and aluminum

Product parameters

| Material | steel, stainless steel, aluminum, copper, brass, alloy, etc. |

| Thickness | 0.1mm to 12mm, as your request |

| Sizes | 1) According to customers' drawings 2) According to customers' samples |

| Surface treatment | zinc, nickle, chrome plating, powder coating, painting, etc. |

| Packing | Polybag+Carton box+Wooden case/Pallet, according to customer's request |

| Shipment | 1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive 2) By air to air port, usually, 3-4 days to arrive 3) By Sea port, usually 15-30 days to arrive |

| Delivery Time | depend on the quantities, usually around 10 days. |

| Payment Term | T/T, L/C, Trade Assurance |

| Certification | ISO |

| Application | widely used on construction, industry. |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Industrial Machine Frames

- Reason: Industrial machine frames require strong, rigid structures that can endure heavy use. Sheet metal is used for its ability to form complex shapes while maintaining structural integrity, making it suitable for machinery in high-demand environments.

Automotive Body Panels

- Reason: Sheet metal fabrication provides lightweight, durable, and cost-effective solutions for automotive body panels. It allows for precise shaping and molding to fit specific designs while ensuring strength and resistance to impact.

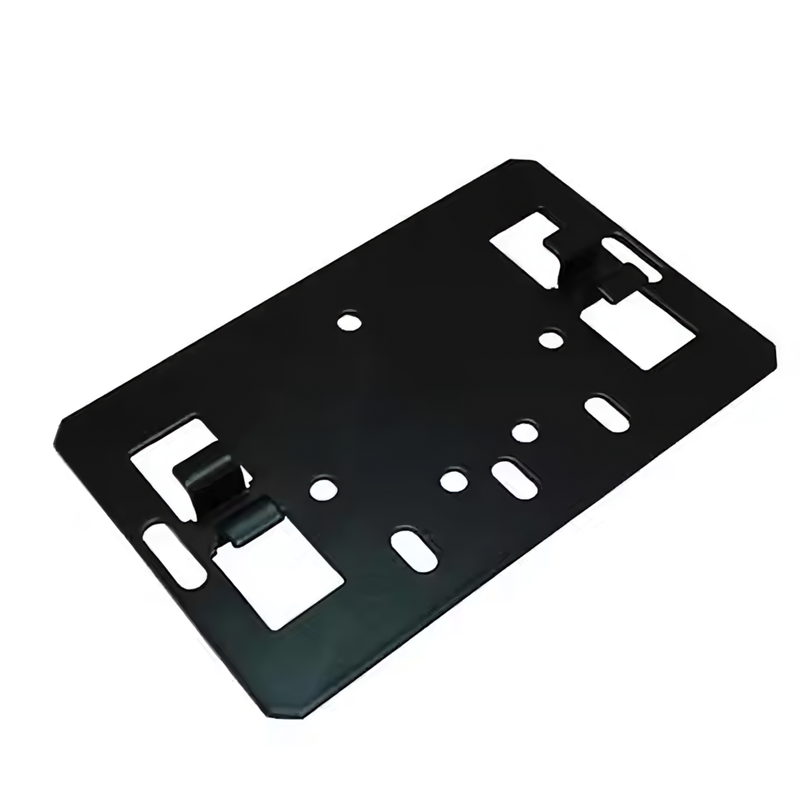

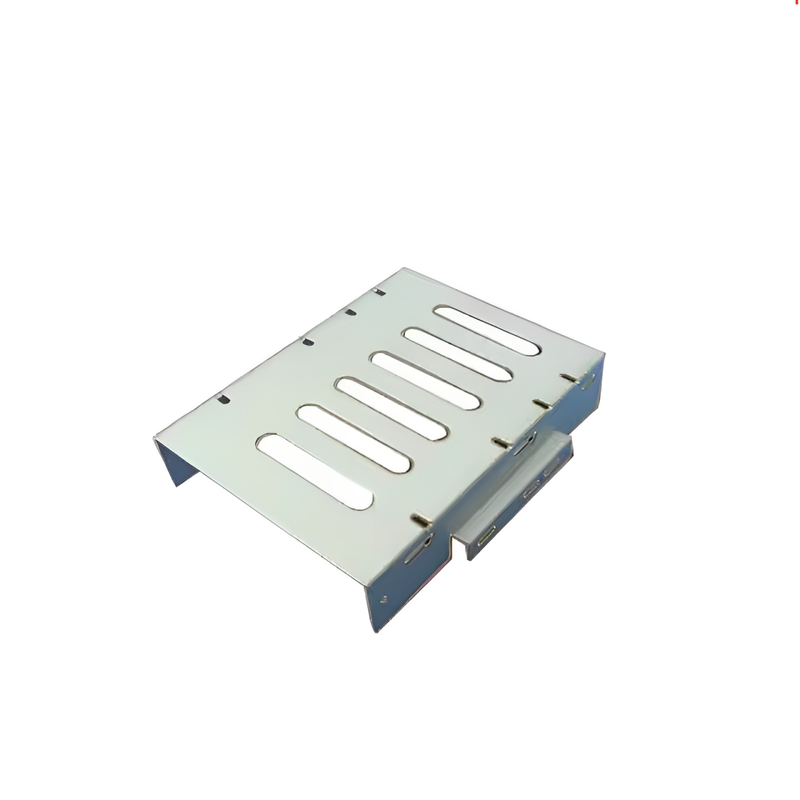

Electronic Housings

- Reason: Sheet metal fabrication is used to create precise, durable housings for electronics, protecting internal components from physical damage and interference. It ensures that the enclosure is lightweight and has the necessary strength to shield electronic devices.

Material

Aluminum Alloy

Iron

Stainless Steel

Quality Control

Quality control for stainless steel sheet metal fabrication involves thorough inspections for dimensional accuracy, surface finish, and weld integrity. It ensures that the material meets specifications for strength, durability, and corrosion resistance. Testing is conducted to verify that the final product meets industry standards, performs reliably in its intended application, and maintains high-quality standards for long-term use in various environments

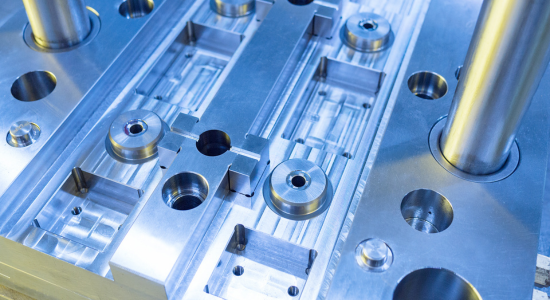

Processing capability

The processing capability of stainless steel sheet metal fabrication includes advanced techniques such as laser cutting, CNC punching, precision bending, and welding. These processes enable the production of complex shapes, custom components, and assemblies, ensuring high accuracy, strength, and corrosion resistance. The ability to work with various stainless steel grades and thicknesses allows for flexibility in meeting specific design requirements for a wide range of industries, including automotive, construction, and food processing. Additionally, surface treatments such as polishing and coating can be applied to enhance durability and aesthetics

Additional processes

Additional processes for stainless steel sheet metal fabrication include surface finishing techniques such as polishing, coating, anodizing, and powder coating to improve appearance and durability. Post-fabrication processes like deburring, welding, and assembly are also used to meet precise specifications and ensure the final product performs optimally while maintaining strength and resistance