Product Description

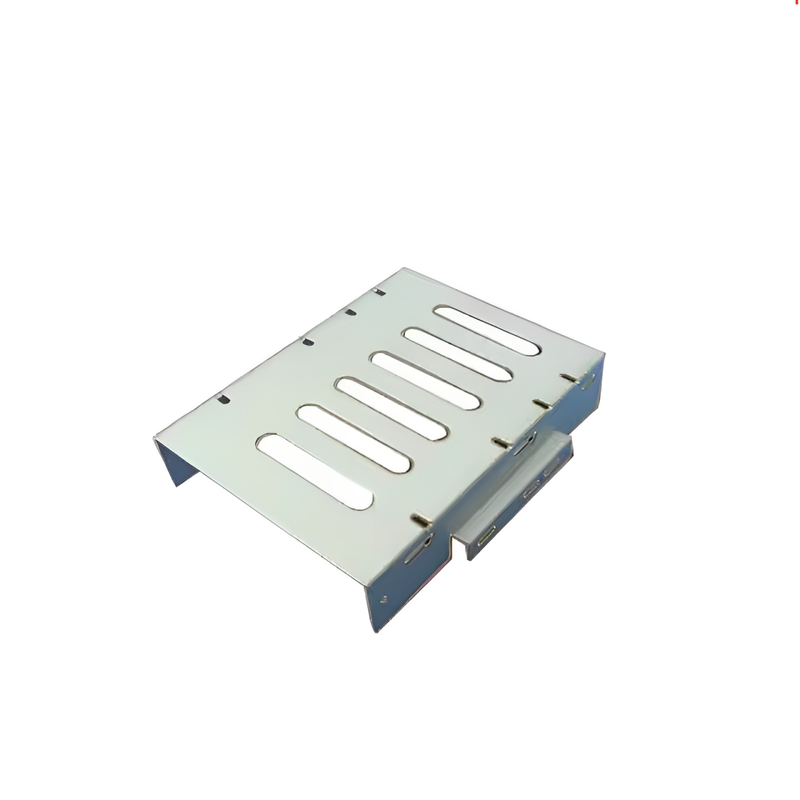

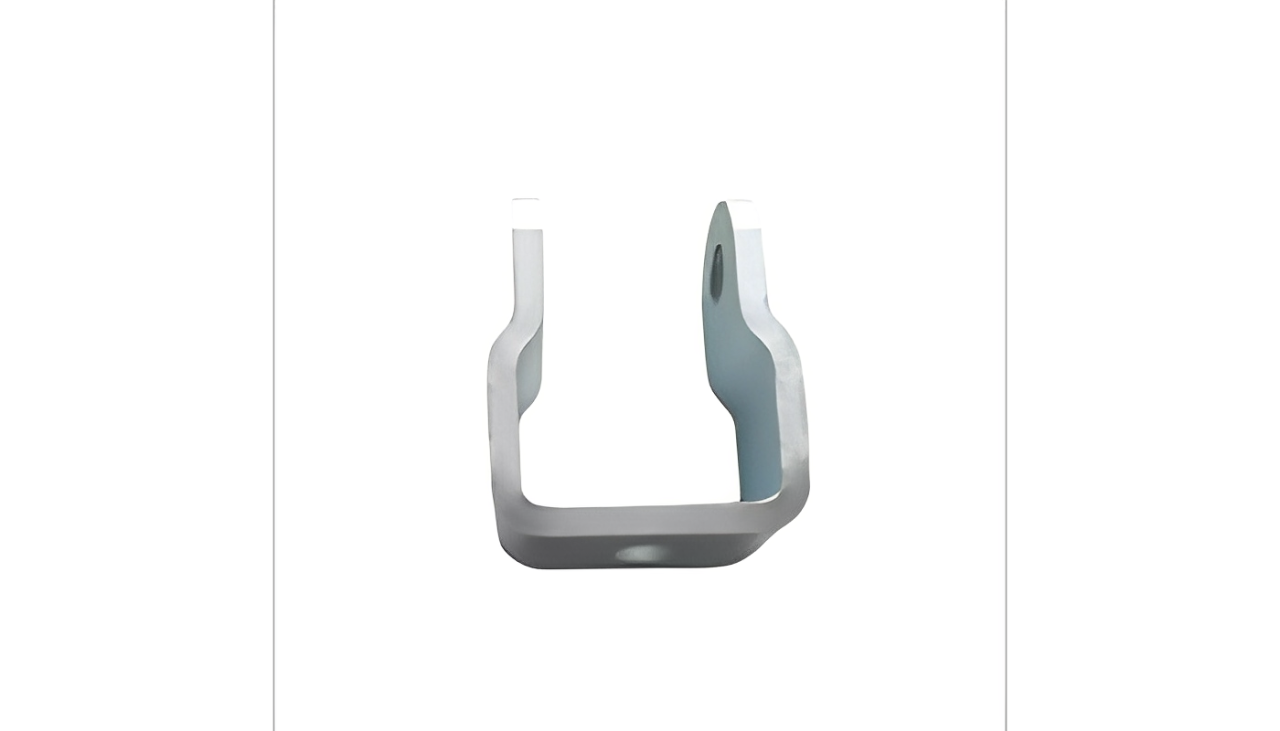

Custom Press Auto Sheet Metal Stamping Shelf Parts are precision-made components for automotive and industrial shelving. Manufactured using advanced stamping technology, these parts offer durability, strength, and a perfect fit for custom designs, ensuring reliable performance in demanding environments.

Product parameters

| material | Carbonsteel ,galvanized sheet,stainlesssteel |

| surface treatment | Zinc , powder coat, hot-dip galvanized,blackening, electroplate |

| machining Process | Stamping , turning,tube bending, welding, milling, CNC lathe |

| usage of products | Furniture fitting, construction hardware , telecom ,auto,machine |

| packing | case, pallet, strong box , by clients request |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Automotive Body Components

- Reason: These parts are used in vehicle manufacturing for components like door panels, fenders, and chassis parts. The stamping process offers high precision, durability, and cost-effectiveness, ensuring that the parts meet safety and performance standards while being lightweight and strong.

Appliance Frames

- Reason: Sheet metal stamping is used for appliance frames, such as those in refrigerators, washing machines, and ovens. The strength, durability, and flexibility of stamped sheet metal allow for the creation of complex shapes that can withstand high heat and heavy usage in everyday appliances

Industrial Equipment Parts

- Reason: Custom stamped sheet metal is used in parts for industrial equipment, such as machine enclosures, brackets, and structural components. The stamping process allows for high-volume production of strong and accurate parts, making them suitable for machinery that requires durability and precision under heavy loads

Material

Aluminum Alloy

Iron

Stainless Steel

Quality Control

Quality control for Custom Press Auto Sheet Metal Stamping Shelf Parts includes strict inspections to ensure dimensional accuracy, surface finish, and structural integrity. Each part undergoes visual checks, measurement verifications, and material testing to meet customer specifications. The process also includes checks for proper fit, strength, and durability, ensuring the parts perform reliably in their intended applications, whether in automotive or industrial shelving systems

Processing capability

The processing capability of Custom Press Auto Sheet Metal Stamping Shelf Parts includes precision stamping, laser cutting, bending, and forming, allowing for the production of complex shapes and designs. Advanced press machines enable high-volume production with consistent quality, while CNC technology ensures precise dimensions and tight tolerances. The process can accommodate a wide range of materials and thicknesses, providing flexibility for various customer requirements in automotive and industrial shelving applications

Additional processes

Additional processes for Custom Press Auto Sheet Metal Stamping Shelf Parts include welding, powder coating, surface finishing, deburring, and assembly. These processes enhance the part's durability, corrosion resistance, and appearance. Powder coating provides a protective layer for long-lasting finish, while welding and assembly ensure structural integrity. Surface finishing techniques like polishing and deburring improve the part's aesthetic and functionality, ensuring a smooth and refined end product suitable for automotive and industrial applications