Product Description

High quality silica sol investment casting: Our stainless steel precision machined silica sol investment casting services provide high precision and accuracy to ensure finish. The silica sol investment casting process allows for complex designs and complex geometry, making it ideal for a variety of applications.

Product parameters

| OEM ODM stainless steel precision machining silica sol investment casting lost wax casting | |||

|---|---|---|---|

| cast | Lost wax casting | Water glass casting | Die casting |

| Materials | Stainless steel 304 316 316L | Alloy steel | Orichalcum |

| Duplex stainless steel 2205 | Carbon steel | aluminum | |

| Heat treatment | Shot blasting | anneal | indurate |

| sandblast | quench | temper | |

| carburizing | normalize | ||

| nitriding | solution | ||

| Casting tolerance | 0.5~5mm | ||

| weight | 0.1kg~100kg | ||

| surface | Mirror satin | Hot-dip galvanizing | Power coating |

Technological Innovation

Investment casting (lost wax casting) :

Principle: First of all, the model is made of wax, and the dimensional accuracy and surface quality of this wax mold are very high. Then the surface of the wax mold is coated with multiple layers of refractory materials, such as silica sol and other binders and quartz powder and other refractory powder made of paint, after drying, hardening to form a shell with sufficient strength. The wax mold is then heated and melted, so that the wax flows out of the gate of the mold shell (this is the process of "losing wax"), and a hollow mold shell is obtained. Finally, the molten metal liquid (such as stainless steel, alloy steel, etc.) is poured into the mold shell, and after the metal liquid is cooled and solidified, the mold shell is broken, and the precision casting is obtained.

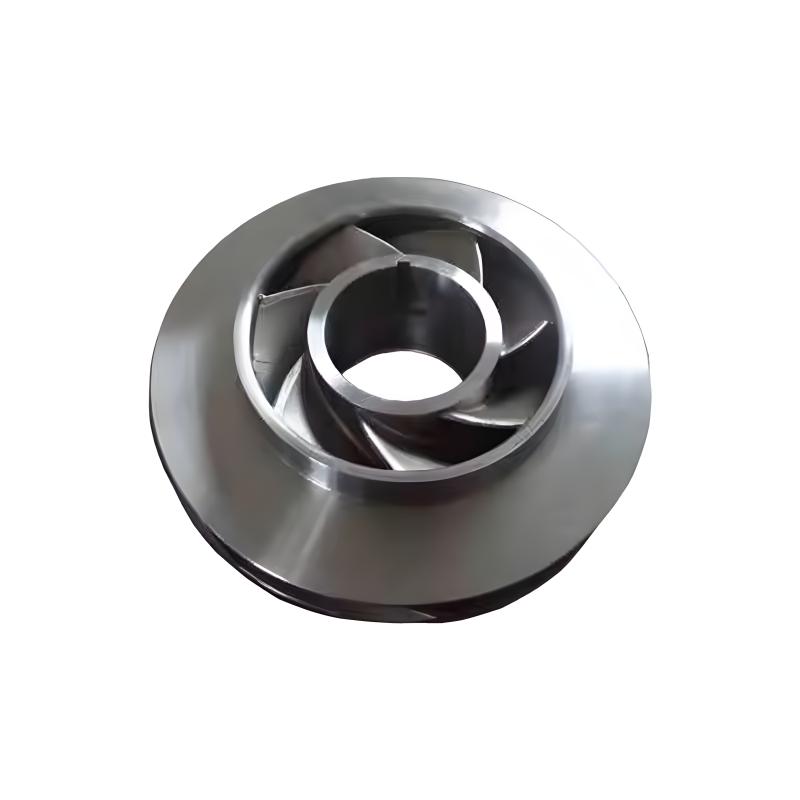

Product Display

High precision

Silica sol investment casting can achieve extremely high dimensional accuracy and the tolerance range can be controlled within a very small range. This makes the production of castings can be perfectly matched with other parts, without too much follow-up processing, greatly improving production efficiency and product quality. Whether it is complex geometry or fine internal structure, it can be accurately copied to meet the needs of aerospace, medical devices, automotive manufacturing and other industries that require high precision.

Excellent material adaptability

Can be applied to a variety of alloy materials casting, such as stainless steel, alloy steel, aluminum alloy and so on. Different materials can meet the performance requirements of different industries and products. For example, stainless steel castings have good corrosion resistance and are widely used in chemical, food and other industries; Aluminum alloy castings have the characteristics of light weight and high strength, and are widely used in aerospace and automobile manufacturing.

Quality Control

Compliance with international standards: Our products comply with international standards such as ISO 9001:2018, CE and TUV, ensuring compliance with global quality and safety regulations.

Application Cases

Precision casting, a wide range of applications: covering machinery manufacturing, chemical, hardware, petroleum, automotive, metallurgy and many other fields, with superb technology to achieve excellent quality, to provide solid support for the development of various industries.