Product Description

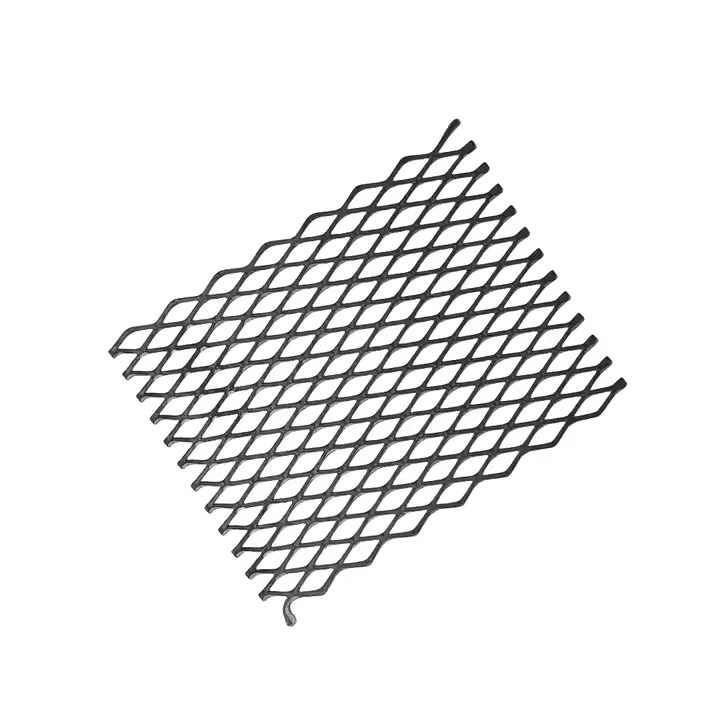

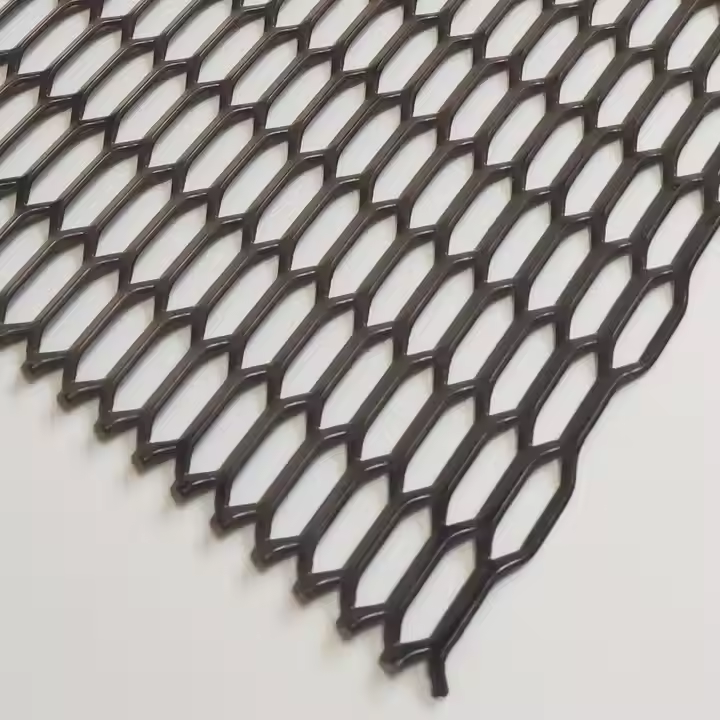

Laser-cut mesh panels are precision-engineered sheets made from various materials such as steel, aluminum, stainless steel, or copper. The mesh is cut using laser cutting technology, which allows for intricate patterns and high-quality finishes. These panels are widely used for architectural, industrial, and decorative applications due to their aesthetic appeal and strength.

Product parameters

| List | Details |

|---|---|

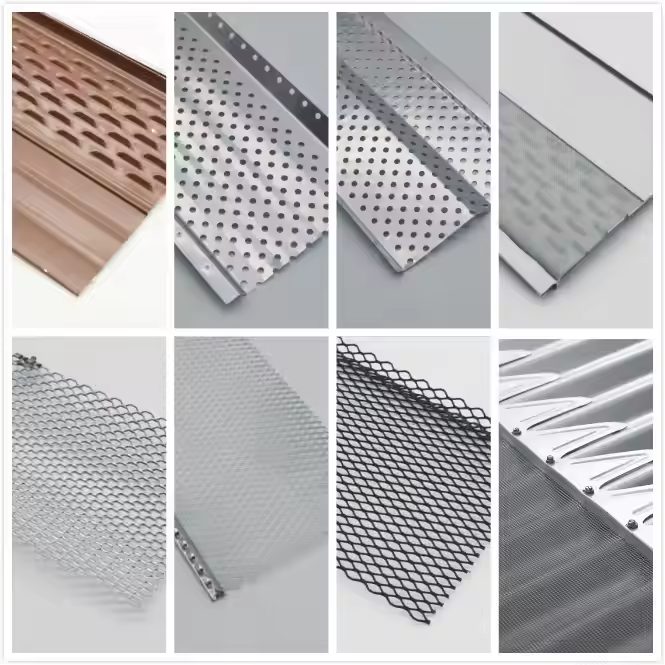

| Product name | Expanded Perforated Metal Mesh Gutter Leaf Guards |

| Weave Style | Twill Weave |

| Technique | Welded Mesh |

| Feature | Corrosion Resistance |

| Surface treatment | Hot Dipped Galvanized |

| Hole shape | Hexagonal Hole,Diamond Hole |

| Certification | ISO9001:2008 |

| Single package size | 20X20X10 cm |

| Single gross weight | 0.500 kg |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Aluminum alloy

Metal Sheet

Copper Sheet

Brass Sheet

Quality Control

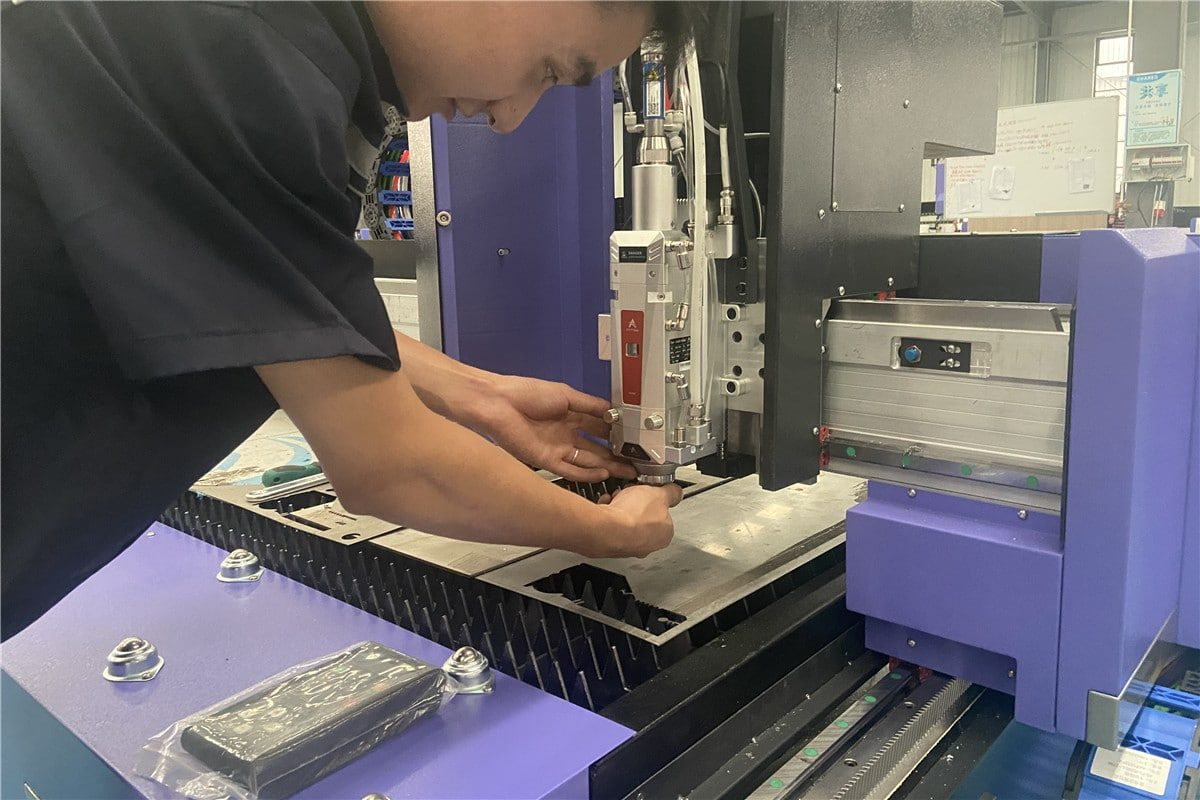

Quality control (QC) in the production of laser-cut mesh panels is essential to ensure that the final product meets both functional and aesthetic standards. Here are the key aspects of QC for laser-cut mesh products

1. Material Quality and Inspection

2. Laser Cutting Precision and Accuracy

3. Laser Cutting Machine Calibration

4. Tolerance Compliance

5. Surface Finish and Aesthetics

6. Structural Integrity and Strength

7. Final Product Inspection

8. Packaging and Handling

9. Documentation and Traceability

The quality control process for laser-cut mesh products ensures that each product is manufactured to the highest standards. From material inspection, machine calibration, dimensional accuracy, and edge finish, to overall visual inspection and packaging, QC is integral in delivering precise, high-quality, and defect-free mesh panels. By maintaining strict QC procedures, manufacturers can ensure that their laser-cut mesh products meet both functional and aesthetic requirements for a wide range of industries.

Processing capability

Laser-cut automotive grilles offer precision, customization, and high durability, making them a preferred choice for both OEM and aftermarket automotive parts. They combine aesthetic appeal with functional performance, ensuring vehicles maintain optimal airflow while achieving a sleek, modern look.

Additional processes

- Vehicle Front Grilles: Enhances the vehicle's exterior while allowing proper airflow to the engine and cooling systems.

- Custom Aftermarket Parts: Laser-cut grilles are also popular in the aftermarket automotive industry, where vehicle owners want to personalize or upgrade their car’s front grille.

- Protection & Functionality: Provides a balance of aesthetics, protection, and functional airflow for cooling radiators and engines.