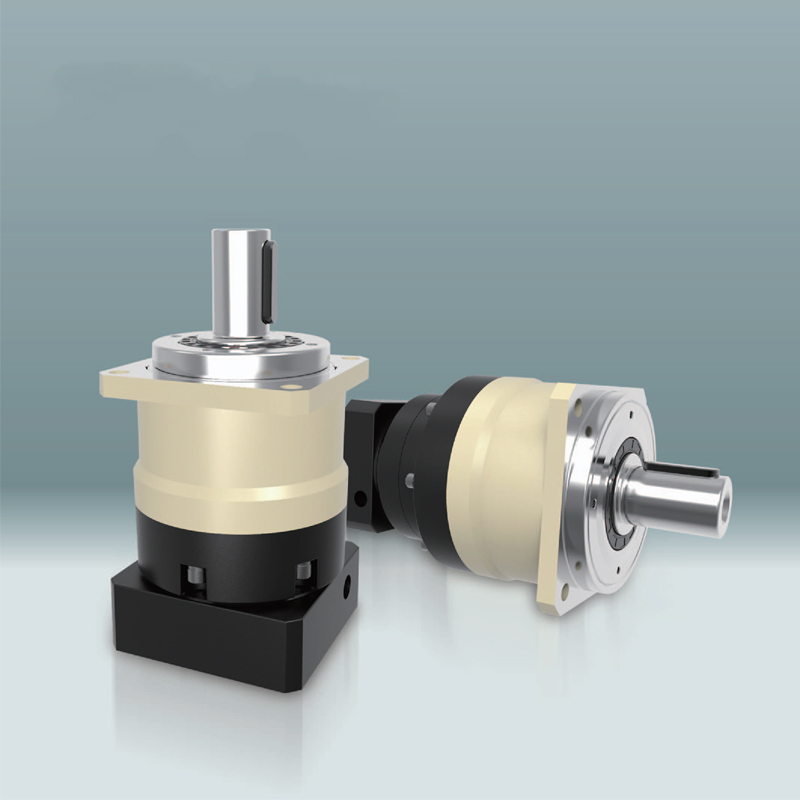

产品描述

精密行星减速机是一款集高精度、高扭矩、高效率、结构紧凑与稳定性强等卓越特性于一身的机械传动关键设备。它依据行星齿轮传动原理设计,太阳轮、行星齿轮与外齿圈精妙配合。在实际应用中,能在诸如机器人关节、数控机床进给等对精度要求极高的场景精准控制误差;可承受建筑起重机、工业搅拌设备等大型机械产生的重载;凭借高传动效率降低能耗与运营成本;其小巧轻盈的结构适配航空航天、医疗仪器等空间有限的设备;

产品参数

| 规格 | 级数 | 减速比 | MYA042 | MYA060 | MYA115 | MYA180 | |

|---|---|---|---|---|---|---|---|

| 额定输出力矩 | Nm | 1 | 3 | 20 | 55 | 208 | 588 |

| 4 | 19 | 50 | 290 | 1050 | |||

| 5 | 22 | 60 | 330 | 1200 | |||

| 6 | 20 | 55 | 310 | 1100 | |||

| 7 | 19 | 50 | 300 | 1100 | |||

| 8 | 17 | 45 | 260 | 1000 | |||

| 10 | 14 | 40 | 230 | 520 | |||

| 2 | 12 | 20 | 55 | 208 | 588 | ||

| 15 | 20 | 55 | 208 | 588 | |||

| 20 | 19 | 50 | 290 | 1050 | |||

| 25 | 22 | 60 | 330 | 1200 | |||

| 30 | 22 | 55 | 208 | 1200 | |||

| 35 | 22 | 60 | 330 | 1200 | |||

| 40 | 22 | 50 | 290 | 1200 | |||

| 50 | 22 | 60 | 330 | 1200 | |||

| 60 | 20 | 55 | 310 | 1100 | |||

| 70 | 19 | 50 | 300 | 1100 | |||

| 80 | 17 | 45 | 260 | 1000 | |||

| 100 | 14 | 40 | 230 | 520 | |||

| 最大输出力矩 | Nm | 12 | 3~100 | 3倍额定输出力矩 | |||

| 额定输入转速 | rpm | 12 | 3~100 | 5000 | 5000 | 4000 | 3000 |

| 最大输入转速 | rpm | 12 | 3~100 | 10000 | 10000 | 8000 | 6000 |

| 超精密背隙 | arcmin | 1 | 3~10 | ≤1 | ≤1 | ||

| 2 | 12~100 | ≤3 | ≤3 | ||||

| 精密背隙 | arcmin | 1 | 3~10 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 12~100 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| 标准背隙 | arcmin | 1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 |

| 2 | 12~100 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| 扭转刚性 | Nm/arcmin | 1.2 | 3~100 | 3 | 7 | 25 | 145 |

| 容许径向力 | N | 12 | 3~100 | 780 | 1530 | 6700 | 14500 |

| 容许轴向力 | N | 12 | 3~100 | 350 630 1300 3000 4000 6200 35000 | |||

| 容许轴向力 | N | 12 | 3~100 | 390 765 1625 3350 4700 7250 25000 | |||

| 使用寿命 | hr | 12 | 3~100 | 20,000 | |||

| 效率 | % | 1 | 3~10 | ≥97% | |||

| 2 | 12~100 | ≥94% | |||||

| 重量 | kg | 1 | 3~10 | 0.5 | 1.3 | 7.8 | 29 |

| 2 | 12~100 | 0.8 | 1.9 | 9 | 33 | ||

| 使用温度 | ℃ | 12 | 3~100 | -10℃~+90℃ | |||

| 润滑 | 1.2 | 3~100 | 合成润滑油脂 | ||||

| 防护等级 | 12 | 3~100 | IP65 | ||||

| 安装方向 | 1.2 | 3~100 | 任意方向 | ||||

| 噪音值(n1=3000rpm) | dB | 12 | 3~100 | ≤56 | ≤58 | ≤63 | ≤67 |

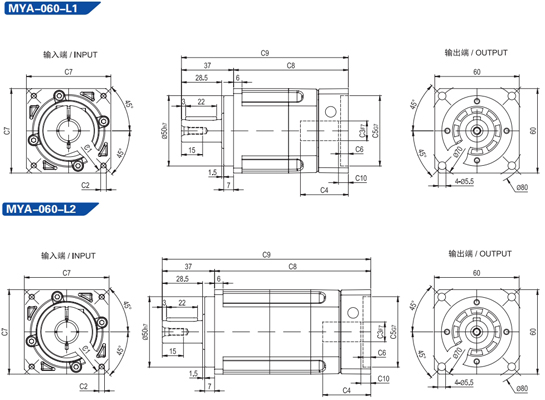

输出轴径

| 尺寸 | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 |

|---|---|---|---|---|---|---|---|---|---|---|

| MYA-060-L1 | ∅66.7 | 4-M4x12 | ∅8 | 34 | ∅38.1 | 5.5 | 60 | 81.5 | 118.5 | 7 |

| ∅70 | 4-M4x12,4-M5x12 | ∅11,∅14 | 34 | ∅50 | 5.5 | 60 | 81.5 | 118.5 | 7 | |

| ∅90 | 4-M5x15,4-M6x15 | ∅19 | 42 | ∅70 | 7 | 80 | 90.5 | 127.5 | 9 | |

| MYA-060-L2 | ∅66.7 | 4-M4x12 | ∅8 | 34 | ∅38.1 | 5.5 | 60 | 110.5 | 147.5 | 7 |

| ∅70 | 4-M4x12,4-M5x12 | ∅11,∅14 | 34 | ∅50 | 5.5 | 60 | 110.5 | 147.5 | 7 | |

| ∅90 | 4-M5x15,4-M6x15 | ∅19 | 42 | ∅70 | 7 | 80 | 119.5 | 156.5 | 9 |

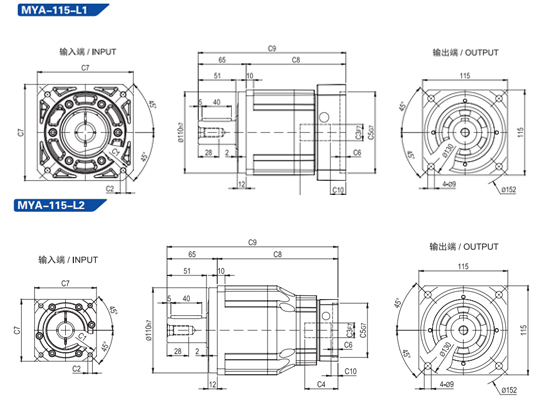

| 尺寸 | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 |

|---|---|---|---|---|---|---|---|---|---|---|

| MYA-115-L1 | ∅145 | 4-M8x20 | ∅19,∅22,∅24 | 62 | ∅110 | 8 | 130 | 135 | 200 | 21 |

| ∅200 | 4-M12x30 | ∅35 | 82 | ∅114.3 | 10 | 180 | 155 | 220 | 28 | |

| MYA-115-L2 | ∅90 | 4-M5x15,4-M6x15 | ∅19 | 43 | ∅70 | 7 | 80 | 156 | 221 | 9 |

| ∅100 | 4-M6x15 | ∅16,∅19 | 43 | ∅80 | 7 | 86 | 156 | 221 | 9 | |

| ∅115 | 4-M8x20 | ∅19,∅22,∅24 | 56.5 | ∅95 | 10 | 100 | 172.5 | 237.5 | 17.5 | |

| ∅145 | 4-M8x20 | ∅19,∅22,∅24 | 60 | ∅110 | 8 | 130 | 176 | 241 | 21 |

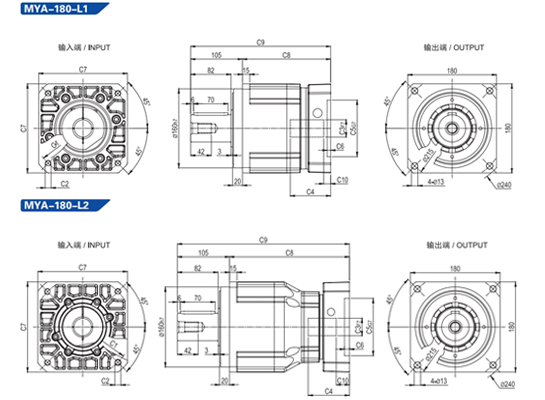

| 尺寸 | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 |

|---|---|---|---|---|---|---|---|---|---|---|

| MYA-180-L1 | ∅200 | 4-M12x30 | ∅35 | 82 | ∅114.3 | 7 | 180 | 179 | 284 | 14 |

| ∅235 | 4-M12x30 | ∅42 | 120 | ∅200 | 10 | 220 | 217 | 322 | 44 | |

| MYA-180-L2 | ∅145 | 4-M8x20 | ∅22,∅24 | 72 | ∅110 | 10 | 130 | 230 | 335 | 20.5 |

| ∅200 | 4-M12x30 | ∅35 | 83 | ∅114.3 | 10 | 180 | 241 | 346 | 26.5 |

*C1-C7是公制标准马达连接板之尺寸,可根据客户要求单独定做。

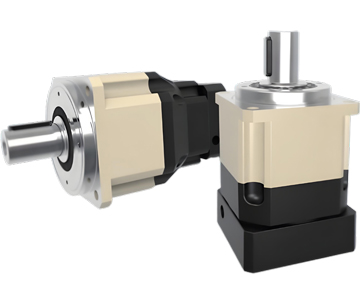

产品展示

精密行星齿轮减速机是我公司自主研发的新一代实用性产品,融合了国内外先进的技术,具有以下一些主要特点:

- 低噪音:低于65db。

- 低背隙:单级可达1弧分内,双级可达3弧分内。

- 高效率:单段式在95%以上,双段式在92%以上。

- 高输入转速:可达8000RPM。

- 高扭矩:比一般标准行星减速机扭矩高。

- 高稳定性:采用高强度合金钢材,整颗齿轮经硬化处理,非只有表面硬化,确保高减速比:采用模组化设计,行星齿箱可相互连结,速比可达1/1000以上。

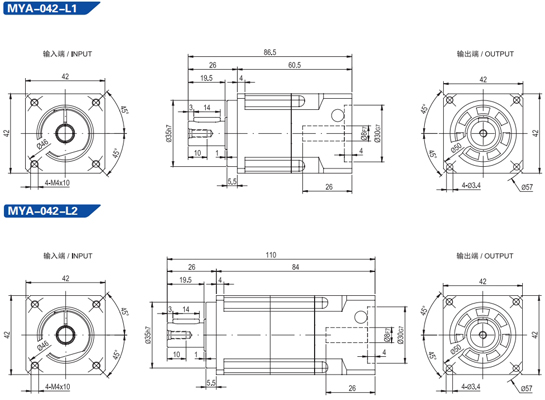

尺寸和接口

品控

进料皆需通过严格的检测,确保材质正确无误后才进入加工阶段,为确保毎个零件都与图面绘制相同, 必须经过三次元检测仪100%检测都在公差范围,才会入组装线进行组装。

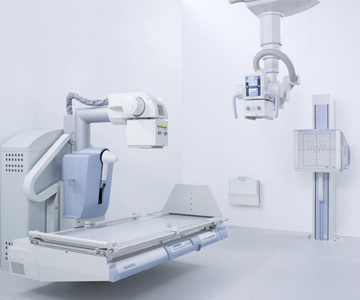

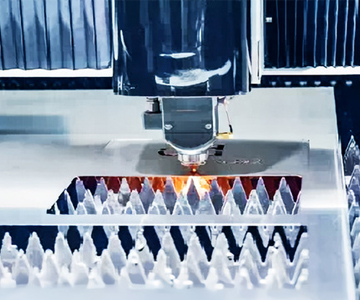

应用案例

精密行星齿轮减速机被广泛应用于以下领域:

1.航空航天、军事产业。

2.医疗卫生、电子信息技术产业。

3.工业机器人、生产自动化、数控机床制造产业。

4.汽车制造、纺织、印刷、食品、冶金、环保工程、仓储物流等产业