Product Description

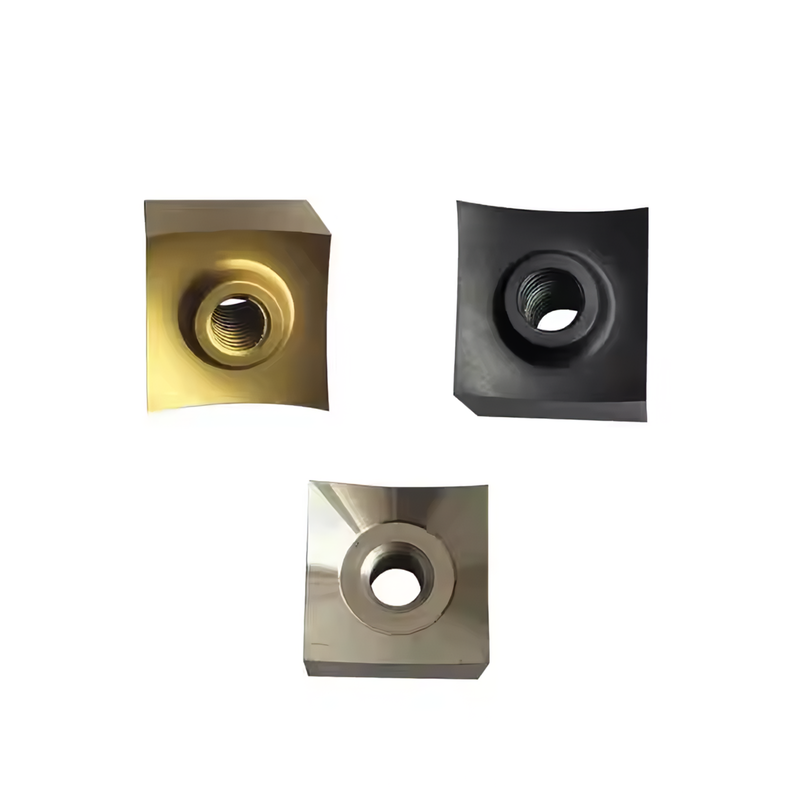

Our brass forged parts are manufactured through high-precision casting techniques, ensuring superior strength, durability, and resistance to wear. These components are crafted to meet demanding industrial standards, offering exceptional performance and reliability in various applications, from machinery to custom assemblies. Perfect for industries seeking high-quality, resilient brass solutions.

Product parameters

| Item | Parameters |

|---|---|

| Specification | Customized,customer required,customer's drawings |

| Material | Carbon steel,Stainless steel,Alloy steel,Heat resistant steel,Brass,Copper, etc. |

| Application | Automobile, agricultural machinery, furniture, construction, home appliances, electronics. |

| Process | Forging |

| Machining | Punch, Press, Spinning lathe, Precision punch |

| Heat treatment | Quench and tempering,Carburizing,Nitriding,Induction hardening,Normalizing, |

| Unit weight | 5g-300kg |

| Certificate | KQA-Q172962 KQA-TS150225 KQA-E23907 |

| Finish | Polishing,Powder coating,Painting,Nickel plating,Chrome plating,Hot galvanize,Galvanizing, Electrophoresis,Anodizing |

| Service | Weekly report,Key node report,Any questions will be answered within 24 hours. |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Plumbing Fixtures

Durable and corrosion-resistant, ideal for valves, faucets, and pipe fittings.

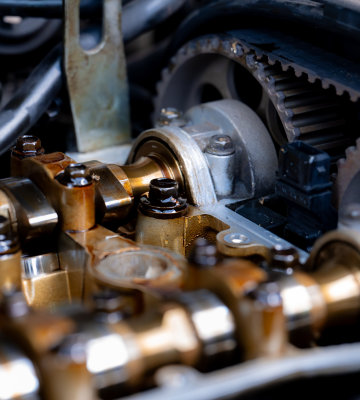

Automotive Components

Commonly used for gears, bushings, and connectors due to their strength and precision.

Industrial Machinery Parts

Used in gears, bearings, and various machine components for enhanced durability and performance.

Quality Control

Quality control in casting is essential to ensure that components meet the required standards. This process involves checking materials, supervising the casting steps, and inspecting the finished products for quality.

- Material Inspection: Verifying the quality of materials like cast iron, aluminum, or other metals to make sure they meet the necessary standards.

2.Casting Process Monitoring: Watching over the casting process, from mold preparation and melting metal to pouring, to prevent mistakes during production.

3.Final Product Inspection: Checking the finished cast parts for defects such as cracks, air pockets, or warping that could affect their strength and performance.

4.Testing Mechanical and Physical Properties: Testing the strength and durability of the parts to ensure they meet the required performance standards.

Processing capability

Processing capability refers to a manufacturing process's ability to produce products that meet quality standards. It involves factors such as the maximum production output within a given time, the ability to maintain accurate dimensions and tolerances, the types of materials that can be processed effectively, the flexibility to adjust for different designs and sizes, and the presence of systems to monitor and maintain quality throughout production

Additional processes

Additional steps in manufacturing include precision machining, heat treatment to improve material strength, surface finishing for better looks and durability, welding and assembling parts, as well as quality checks, protective coating, and packaging for safe delivery. These steps improve product quality and boost production efficiency to meet customer needs