Professional customer service

Brand-Offical Supplier(BO)

2024 Years

Brand-Offical Supplier(BO)

2024 Years

Company Infomation

Company Profile FOUNDING

Innovation as the driving force, quality to survive

Nantong Fangding Precision Casting Co., Ltd. is located in Nantong Tongzhou Bay High-tech Industrial Park 9, Tongzhou Bay Development Zone is located in the north wing of the Yangtze River estuary, Jiangsu River economic belt and coastal economic belt of the "T" intersection, is the Nantong Municipal Committee and government to build the city's efforts in the coastal new area, with a linear distance of 80 kilometers from Shanghai, is the Yangtze River Delta north wing of the most potential for development of the bay.

The company covers an area of 25 acres, the total power of 515 kilowatts, 120 employees, including 8 engineering and technical management personnel, including 5 bachelor degree or above, 1 master degree. The company has a sound ISO9000-2000 quality management system. Casting production, technology and testing means are complete, with strong product quality assurance capabilities. At the same time, the enterprise is also constantly introducing the world's advanced technology, the introduction of a large number of professional technical personnel, the expansion of advanced technical transformation equipment and production equipment, the technical force of the enterprise is becoming increasingly strong, economic strength is also constantly developing and growing.

The main processes adopted by the company are: medium frequency electric furnace melting process, water glass shell making process, silica sol shell making process, silica sol + water glass composite shell making process.

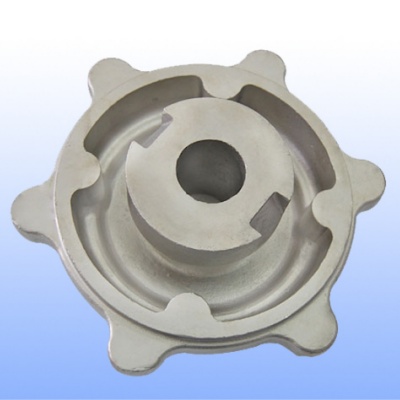

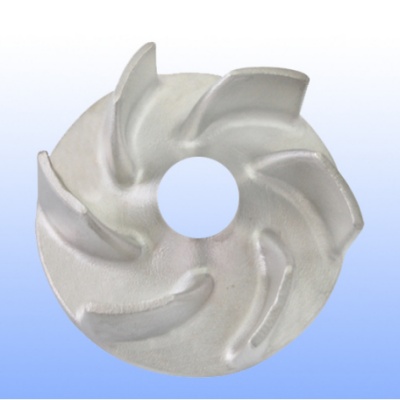

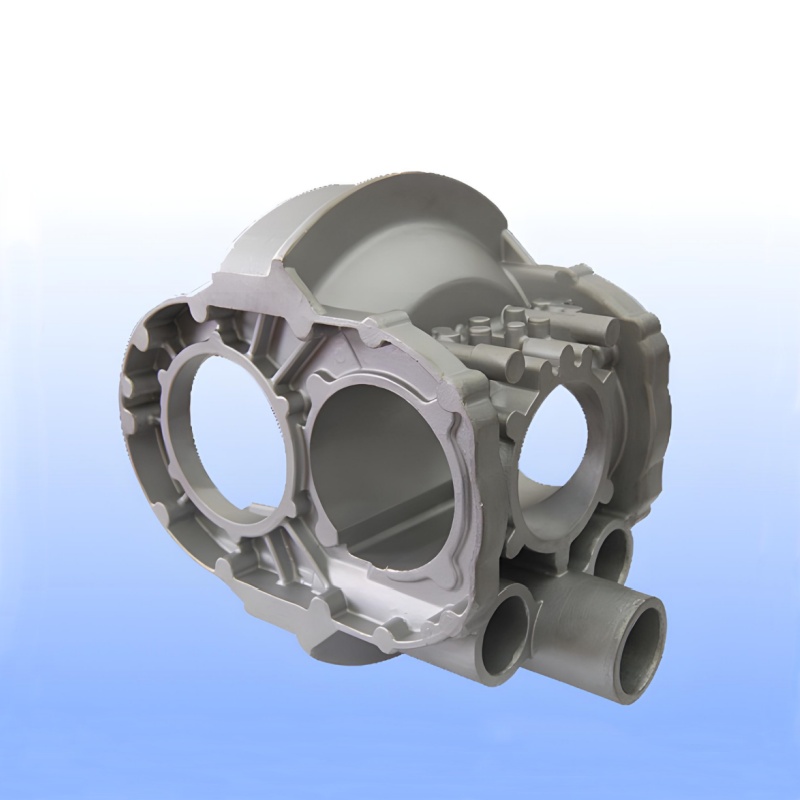

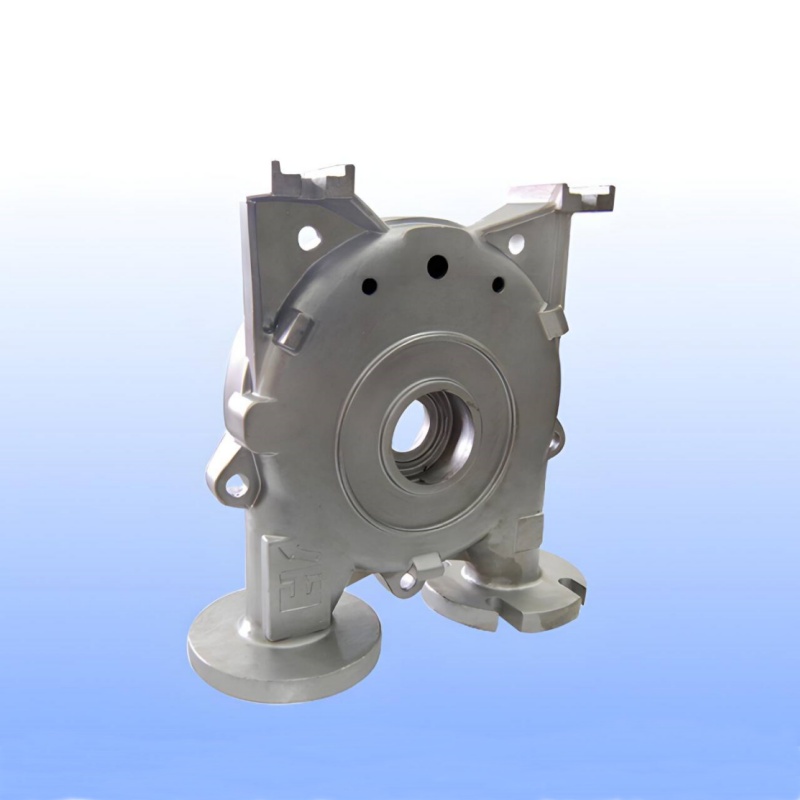

The enterprise adopts advanced investment casting technology, producing all kinds of stainless steel, alloy steel, carbon steel and other materials of precision casting parts, more than 100 kinds of castings, annual production capacity of more than 1000 tons. Products are mainly exported to Italy, Switzerland, the United States, France, Canada and other countries, and to Jiangsu and Zhejiang area machinery manufacturers supporting.

The company based on excellent product quality, competitive price, reliable reputation and customer satisfaction service, to win the recognition of customers, and become their high-quality suppliers. The company always follows the "quality first, customer first" purpose, to "5S" quality management control, and adhere to the implementation of continuous improvement.

Company Certificate

Company Case

Investment casting (lost wax casting) :

Principle: The selection of appropriate investment materials (such as paraffin) to manufacture investment molds; Repeat the process of dipping refractory paint and spreading refractory sand on the investment mold, hardening the shell and drying; Then the internal investment mold is dissolved to obtain the cavity; Calcined shell to obtain sufficient strength, while burning off the remaining investment material; Finally, the required metal material is poured, solidified and cooled, and the sand is cleaned after hulling, so as to obtain the finished product with high precision.

Features: It can produce castings with high dimensional accuracy, good surface quality and complex shape, close to the final shape of the part, and can be used directly without processing or little processing, which is an advanced process of near-net shape formation. Widely used in aviation, weapons, electronics, petroleum, chemical, energy, transportation, light industry, textile, pharmaceutical, medical equipment, pumps and valves and other sectors.

Ceramic mold casting:

Principle: Use ceramic paste to make a cast to produce castings. Ceramic slurry is composed of ethyl silicate hydrolysate and fine refractory sand with relatively pure texture and high thermal stability (such as fused quartz, zircon, corundum, etc.). In order to make the ceramic slurry gel in a short time, calcium hydroxide or magnesium oxide is often added as a catalyst.

Features: The surface roughness of ceramic castings can reach Ra10~1.25 microns, and the dimensional accuracy is as high as 3~5, which can achieve the purpose of less and no cutting. Short production cycle, high metal utilization rate, mainly used for casting large thick wall precision castings and various molds

Metal mold casting

Principle: The liquid metal is poured into the metal mold, the mold is filled under the action of gravity or other external forces, and the casting is obtained after cooling and solidification. Metal molds can be used repeatedly.

Features: The cooling speed of the casting is fast, the structure is dense, and the mechanical properties are good. High production efficiency, suitable for mass production of castings with simple shape and high dimensional accuracy requirements, such as aluminum piston, copper sleeve, etc.

Pressure casting

Principle: The liquid or semi-liquid metal is quickly pressed into the metal mold cavity under high pressure and solidified. Pressure casting is usually performed using a die casting machine.

Features: High production efficiency, high dimensional accuracy of castings, good surface finish, can cast thin-wall parts with complex shapes. However, the equipment cost is high, and the manufacturing of die-casting molds is difficult and costly, which is suitable for the production of small, thin-walled, high-precision parts such as auto parts and electronic product shells.

Our Products

Our Services

Non-standard customization

Good selection

Cooperative partner