Transportation

Cooperative Supplier(CP)

10 Years

Cooperative Supplier(CP)

10 Years

Company Infomation

CHPI ENGINEERING (THAILAND) COMPANY LIMITED

specializes in high-precision component manufacturing, automation systems, and metalwork, dedicated to delivering international standard quality across diverse industries. With extensive experience and a skilled team, we are well-equipped to meet complex design and manufacturing requirements, including jig fixtures, machinery parts, automated conveyor systems, and metal and welding work that demand precision and high-quality standards.

Our company is equipped with state-of-the-art machinery and tools, such as CNC milling, laser cutting, EDM, and grinding machines, along with high-precision inspection equipment capable of achieving accuracy up to ±0.003 mm. We offer made-to-order manufacturing to accommodate the unique demands of various industries, and our services cover every step, from design, prototyping, and assembly to quality inspection and timely delivery. Our expertise extends to both 2D and 3D design, tailored precisely to each client's concept and specifications. We also provide machinery maintenance services to minimize risks and enhance efficiency in our clients' production processes

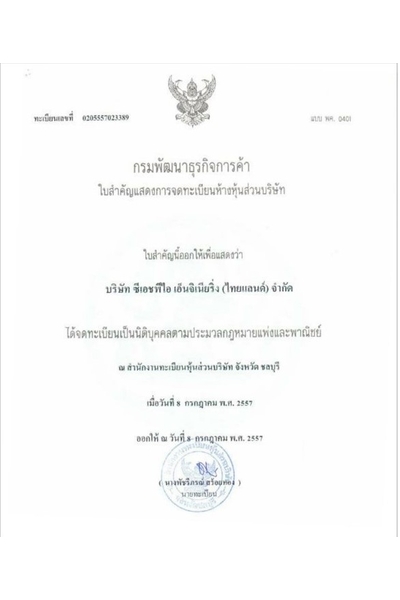

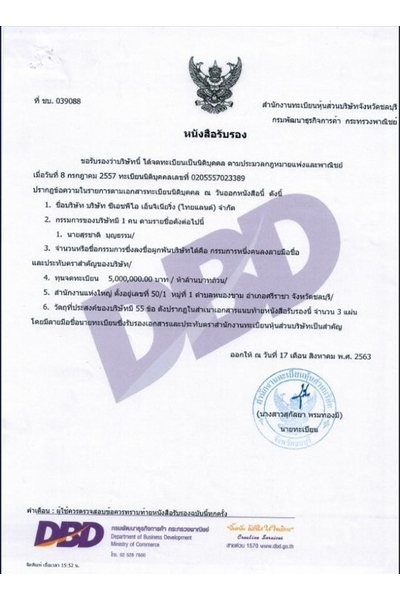

Company Certificate

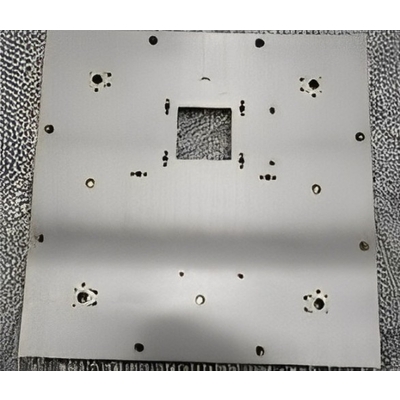

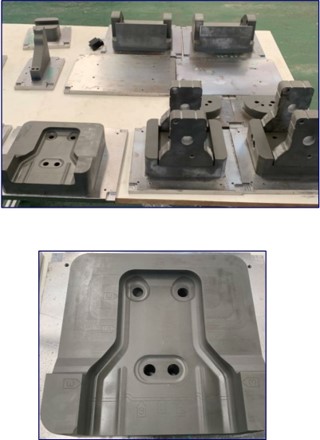

Company Case

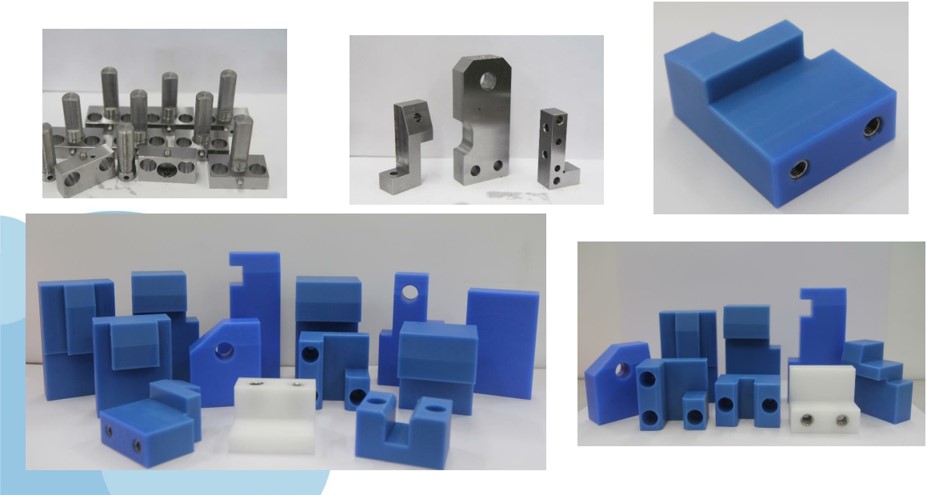

Products from CHPI ENGINEERING (THAILAND) Co., Ltd. are typically high-precision parts and equipment designed to meet specific customer requirements. Here are some examples:

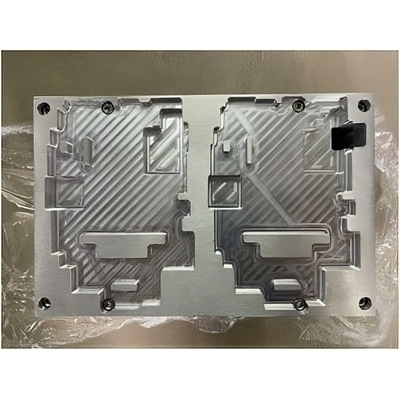

Jigs & FixturesDescription: Jigs and fixtures are tools used to hold workpieces in place during production, allowing machines to work accurately and reducing errors.Example: A jig fixture for automotive assembly, which secures small or complex parts in place to ensure precise assembly in the correct position.

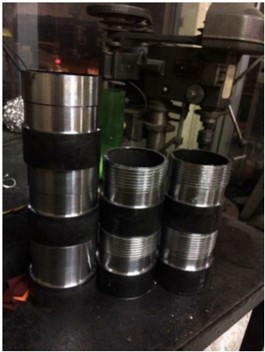

High-Precision Machine Parts (Precision Parts)Description: These parts are produced with high precision for use in machinery that requires accuracy in operation.Example: A spindle shaft used in industrial machines, which needs precision in rotation to avoid vibrations and maintain the machine's performance.

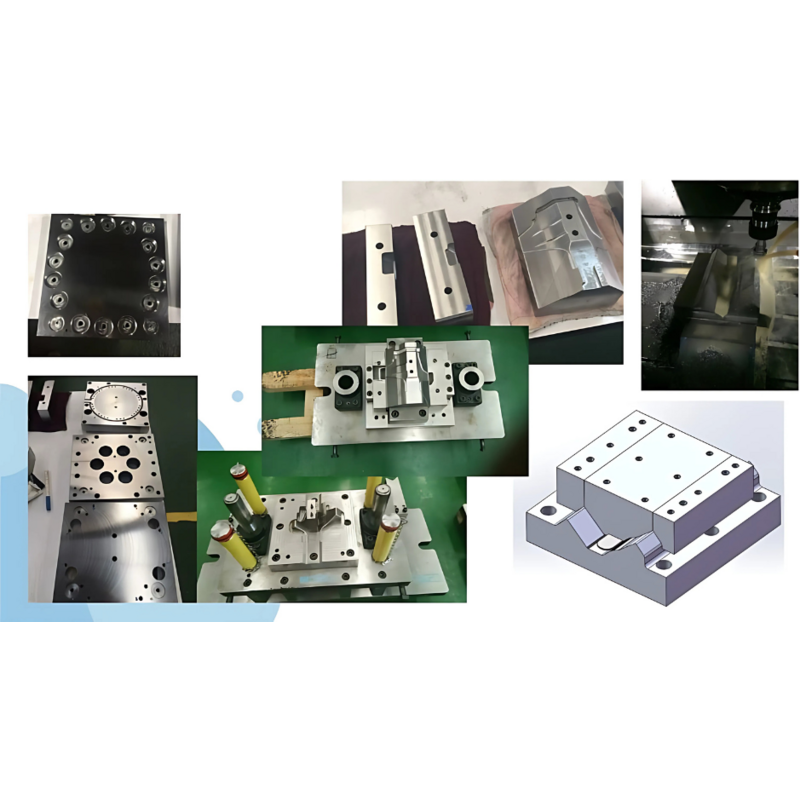

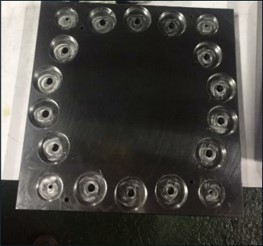

Molds

Description: Molds are used to shape materials, such as metal or plastic, into the desired form for mass production.

Example: A metal mold for automotive parts, such as covers or complex-shaped components

Our Services

1 Year warranty

After-sale service

Cooperative Partner