Professional engineers, Consulting without worries

Brand-Offical Supplier(BO)

4 Years

Brand-Offical Supplier(BO)

4 Years

Company Infomation

HUAXINLIAN TECHNOLOGY

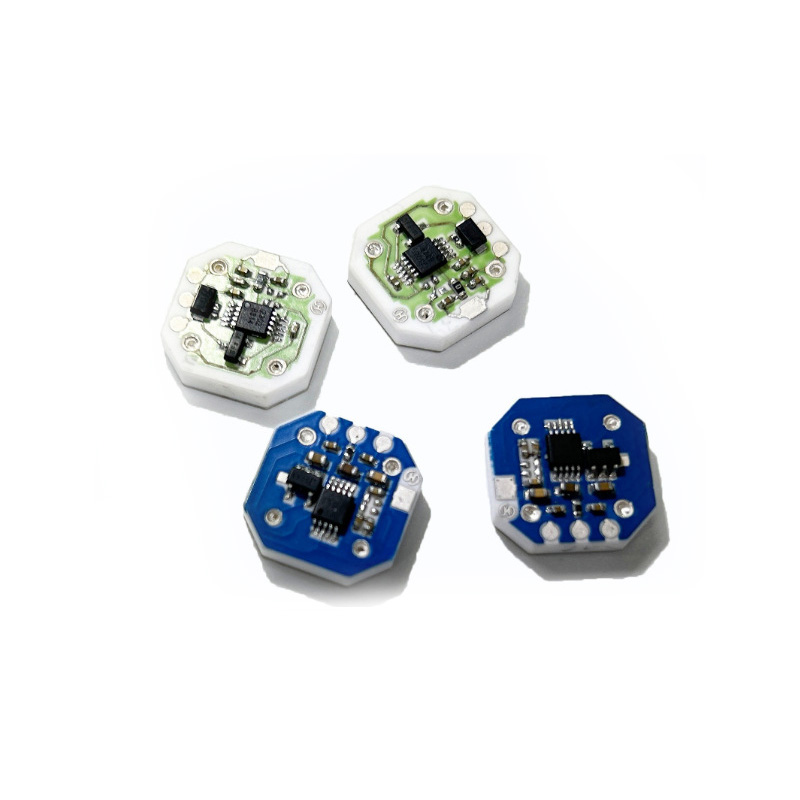

Huaxinlian Technology is an industry-leading high-tech enterprise that focuses on the research and development, manufacturing and sales of ceramic pressure sensors. Its products include ceramic pressure sensor cores, ceramic modules and pressure transmitters. They are widely used in automobiles, air conditioning and refrigeration, oil and gas pipelines, industrial control, aerospace and smart water services, providing these industries with high-quality pressure sensing underlying devices, and promoting the rapid development of the domestic automobile, Internet of Things and artificial intelligence industries. In 2022, Huaxinlian Technology passed the "National High-tech Enterprise" certification.

The company has a dust-free workshop of more than 4,000 square meters, equipped with a fully automated production line, which can produce more than 20,000 ceramic cores per day and more than 7 million per year. With strong R&D capabilities and rigorous production processes, the high quality and reliability of the products are ensured. So far, the company has obtained more than 50 patents and successfully passed ISO9001 and IATF16949 certifications. Huaxinlian Technology is committed to innovation, providing global customers with excellent innovative products and high-quality technical services, and jointly promoting the rapid development of the sensor industry.

Company Certificate

Company Case

Industrial Control

In the field of industrial control, ceramic sensors are playing an indispensable and key role. They have excellent high temperature resistance, corrosion resistance and wear resistance, and can operate accurately and stably in extremely harsh industrial environments. Whether it is monitoring temperature changes in a high-temperature furnace or detecting the concentration of substances in strong acid and alkali solutions, ceramic sensors can provide highly reliable data support, helping industrial production processes to achieve precise control and efficient operation.

Ceramic sensors, with their unique physical and chemical properties, have injected powerful impetus into the industrial automation process. They have extremely high sensitivity and fast response time, and can accurately measure various physical quantities such as pressure and humidity. In automated production lines, they can provide real-time feedback on the operating status of equipment, ensuring that all links are closely connected and running correctly, greatly improving the safety and product quality of industrial production, reducing equipment maintenance costs and failure risks, and have become one of the core components of modern industrial control systems.

Water treatment

In the complex process of water treatment, ceramic pressure sensors are accurate "pressure guards". With excellent chemical stability, they are not afraid of the erosion of various acidic and alkaline substances in the water, and continuously and stably monitor the pressure changes in the water pipe network, filtration devices and water storage containers. Whether it is the strong impact of high-pressure water flow or the subtle fluctuations of low-pressure trickles, they can be keenly captured, providing key data to ensure the smooth operation of the water treatment system, ensuring that every drop of water can complete the purification, transportation and distribution under appropriate pressure conditions.

Ceramic pressure sensors also demonstrate excellent reliability and durability in water treatment. Their high temperature resistance and wear resistance enable them to adapt to working conditions such as frequent start and stop of water treatment equipment and changes in water temperature. When the water pump is working, accurate pressure measurement helps to achieve efficient and energy-saving operation; in the sewage treatment process, stable pressure monitoring ensures the orderly progress of sludge treatment and sewage discharge. It is not only an important monitoring tool for water treatment processes, but also the key to improving the overall performance of water treatment systems, reducing operating costs, and realizing intelligent management, silently guarding the circulation and recycling of water resources.

Home Appliances

Ceramic pressure sensors are widely used in the field of home appliances. They accurately sense the weight of clothes and water level pressure in the washing machine and intelligently control the washing process. They can also accurately monitor the extraction pressure of coffee machines to ensure stable coffee quality, providing key support for the intelligentization of home appliances.

In home appliances such as smart air fryers and electric pressure cookers, ceramic pressure sensors rely on their stability and accuracy to closely monitor pressure changes inside the pot, allowing precise control of cooking temperature and time, greatly improving the ease of use and performance of home appliances.

Instrumentation

Ceramic pressure sensors are like precise "data probes" in instruments. In high-precision pressure measuring instruments, their excellent stability and sensitivity can capture extremely subtle pressure changes, providing a reliable data foundation for scientific research experiments and industrial precision testing.

In meteorological instruments, ceramic pressure sensors are not afraid of wind and rain erosion and sudden temperature changes, and can stably monitor air pressure fluctuations, helping to improve the accuracy of weather forecasts. In automotive instrument systems, they sense key data such as oil circuit pressure in real time to ensure that the vehicle's operating status is under control, and are an indispensable core component for instruments to achieve efficient and accurate measurement.

Our Products

Our Services

Two-year warranty, Quality assurance

Support customization