Agricultural machinery

Cooperative Supplier(CP)

2024 Years

Cooperative Supplier(CP)

2024 Years

Company Infomation

Tate Rubber is a professional manufacturer of rubber parts for the chassis of construction machinery and agricultural machinery. We are committed to providing our customers with professional technical services, quality products and timely and thoughtful service to help them achieve success in their respective fields.

For OEM customers, Tate's excellent technical team provides one-stop technical support. Customers can either use our existing specifications or customize according to their needs. During the design process, we fully communicate with the customer's technical team, design the structure of the track according to the customer's chassis frame and wheel train selection, and design the rubber formula according to the weight, speed and working conditions of the machine. This not only ensures a good match between the chassis and the track, but also ensures the stable and reliable performance and quality of the product.

In terms of after-sales accessories, our product specifications are complete, covering almost all commonly used models of construction machinery and agricultural machinery. We provide users with excellent performance products at a reasonable price.

Tate Rubber is technology-oriented and actively expands into new businesses and areas. We continue to explore the limits of rubber performance, so that the track can adapt to faster speeds, greater machine weight, more extreme conditions, which is particularly important in the military field. In the field of advanced agricultural machinery, the high-power agricultural vehicle track system developed by us can greatly enhance the vehicle's passability, reduce the specific ground pressure, and prevent land compaction.

Tate has been on the road for 20 years. In the future, we will keep an open mind and diligence, continue to move forward on the road of innovation, and provide our customers with better solutions, better products and more thoughtful service.

Company Certificate

Company Case

Strong off-road performance: Military tracked vehicles can cross a variety of complex terrain, such as mountains, jungles, deserts, rivers, etc. In mountain warfare, the track can be adapted to steep hills and rugged mountain roads, and its good adhesion enables the vehicle to climb steep slopes. For example, the main battle tank can climb a 30° -40 ° hill with its tracks, which is difficult for wheeled vehicles to reach.

In the desert environment, the track can distribute the weight of the vehicle and prevent the vehicle from getting stuck in the sand. Because the track has a large contact area with the sand and a small pressure per unit area, it can travel even on soft sand dunes.

Good stability and load carrying capacity: Tracked military equipment has a low center of gravity, and the track can provide stable support. This makes the equipment more stable during driving, especially when firing, and can effectively reduce the impact of recoil on the balance of the vehicle. For example, when a self-propelled gun fires a shell, the tracked chassis can better withstand the recoil and ensure shooting accuracy.

Tracks are capable of carrying heavier equipment and weapon systems. Heavy tanks can weigh up to tens of tons, and the tracks can evenly distribute these weights on the ground, ensuring that the vehicle can travel and fight normally.

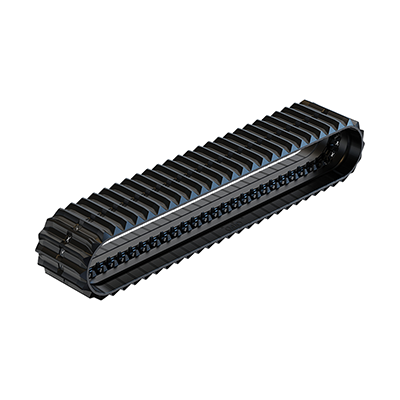

The outermost layer of the paver's rubber track is rubber, which is in direct contact with the ground. This layer of rubber has excellent wear resistance, because the paver needs to move on the road for a long time during the working process, and the rubber outer layer should be able to withstand continuous friction with the ground. For example, in large-scale road paving operations such as highway construction, the rubber outer layer can resist the wear of rough road surface, sand and stone.

At the same time, the elasticity of the rubber outer layer is also very important. It can buffer the vibration generated by the paver during operation to a certain extent, making the paver operation more stable. Moreover, in order to adapt to different work sites, the rubber outer layer usually has a certain pattern design. These patterns can increase the friction between the track and the ground, preventing the paver from slipping when working on special terrain such as slopes.

The skeleton material is the internal support structure of the rubber track. Generally, high-strength fiber fabrics or steel wires are used. The role of the steel wire is to provide strong tensile strength to ensure that the track will not easily stretch and deform when subjected to the weight and tension of the paver. For example, in the rubber tracks of large pavers, steel wires ensure that the tracks retain their original size and shape under complex forces.

Fiber fabric has good toughness and fatigue resistance. It can effectively disperse the stress and prevent local damage to the rubber track in the process of repeated bending and stretching. In the paver's frequent forward, backward and steering operations, the fiber fabric skeleton allows the track to better adapt to these changes.

Our Products

Our Services

Road machinery

National defense industry