After sales services

Cooperative Supplier(CP)

7 Years

Cooperative Supplier(CP)

7 Years

Company Infomation

CONNECTOR EXPERT CO.,LTD.

Key Features of the Production System

Compliance with the ISO 9001 production system, 4M and 5W1H analysis, Ho Ren So activities, and Kaizen for Continuous Improvement (CI). New materials and new supplier approval processes. Engineering inspection - first article approval process (FA), IQC and NC control for all incoming shipments.

NC control in every process, usage manuals (PI/WI) for all process controls. First article inspection and approval during production, all the way to the final piece of the process. Control of production flow processes, quality records control (IQC, IPQC, FQC, OQC). Control of non-conformance records (NCR), control of non-conforming products. 100% electrical conductivity testing for wire harness products. Labeling and product identification system. Monitoring of shipments and traceability.

Company Case

The wiring in an electrical cabinet is an essential component used to connect and supply electrical power to various devices inside the cabinet, such as circuit breakers, switches, relays, or other control equipment. The wiring in the cabinet is selected based on the size and type of electrical current being used, as well as its durability and safety. For example, the wires in the electrical cabinet must have insulation that can withstand high temperatures and voltage to prevent short circuits and electrical hazards. The size of the wires is determined by the current capacity and the distance the wiring needs to travel. Additionally, the wiring should be organized within the cabinet for easy installation and maintenance. The wires typically have durable insulation, such as PVC or XLPE, and may include cooling systems to prevent excessive heat buildup. Furthermore, the installation of wiring in electrical cabinets must comply with safety standards and regulations set by electrical authorities or related agencies to prevent accidents and fire hazards.

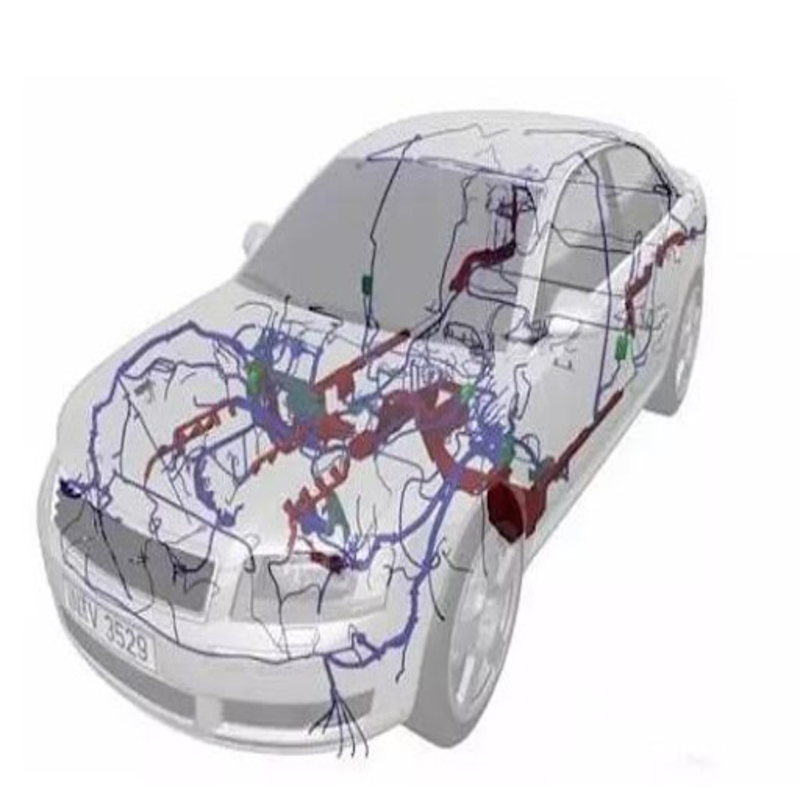

Automotive wiring is an essential component for connecting various electrical systems within a vehicle, such as the lighting system, audio system, engine system, and other equipment. Automotive wires are designed to withstand a variety of environmental conditions, including heat from the engine, moisture, and vibrations. These wires typically feature special insulation, such as PVC or Teflon, which can endure high voltage and offer long-lasting durability. The wires in vehicles are generally small and flexible, making them easy to install in limited spaces, and they use different colors to clearly identify circuits. Additionally, fuses or circuit breakers are used to prevent damage from excessive electrical current. The wires must also be resistant to corrosion and harsh environments, such as oils and chemicals used in vehicles. The vehicle wiring system must provide secure connections and be capable of long-term use without issues.

General Wiring

Engine Wiring

Control Wiring

High Voltage Wiring

Heat-resistant Wiring

Corrosion-resistant Wiring

Audio and Lighting Wiring

Audio and Lighting Wiring

Our Products

Our Services

Technical Services

Transportation service

Cooperative partner