Reply within 24 hours

Cooperative Supplier(CP)

9 Years

Cooperative Supplier(CP)

9 Years

Company Infomation

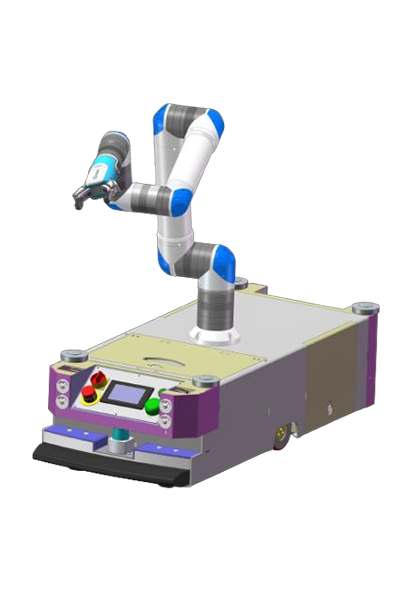

Robot3T is a robot brand of 3C Machinery JSC, one of the leading research and manufacturing companies in robotics and automation.

We have the ambition to successfully develop and commercialize robot products with Vietnamese brand, highly competitive in terms of trade and product value, along with a cost effective strategy in design – manufacturing – maintenance and assistive technology services.

Robot3T focuses on investing in both R&D and commercialization of products, creating highly commercial intellectual property rights, utilizing local advantages and market insights.

In terms of sustainable development and the impact, the Robot3T ecosystem will be gradually developed and perfected in Vietnam, integrating the latest technologies such as artificial intelligence (AI, Big Data and Virtual Sensor, as well as Internet of Things (IoT) solutions, enhance safety, reliability and intelligence for Robot3T products. On the basis of the technology sources and the Robot3T ecosystem, specific applications will be gradually completed and expanded, with a focus on application areas with great economic impact, improved social and quality of life such as Smart Manufacturing and Remote Medicine – Home healthcare (Telehealth & In-home healthcare).

We are very willing to cooperate with domestic and foreign individuals and companies in the research and development of robot-related projects and products.

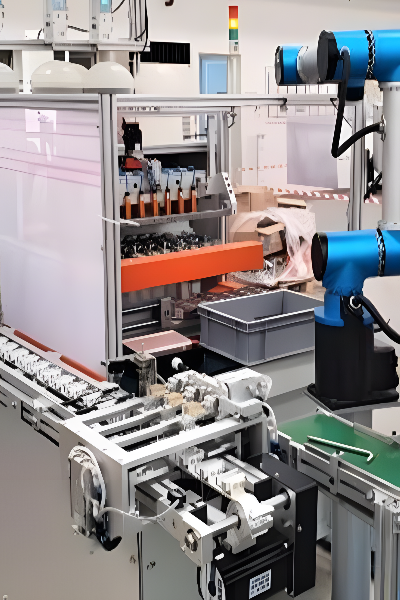

Company Case

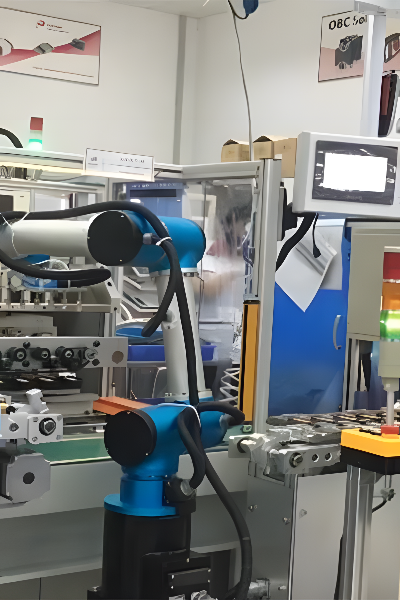

Robotic arms have a wide range of applications in warehouses, and here are some of the main aspects.

Robotic arms can accurately grab and move pallets filled with goods. In large warehouses, the weight of pallet cargo may be large, and manual handling is not only inefficient but also poses safety risks. Robotic arms can unload pallets from transport vehicles and then move them to designated storage areas according to preset programs.

The end effector is usually equipped with a gripper suitable for grabbing pallets, such as a fork gripper or a vacuum suction cup (for some lighter pallets), which can adapt to different types of pallet sizes and materials.

Robotic arms are able to load and unload goods at different heights and locations of warehouse shelves. In automated high-bay warehouses, shelves may be several meters high, and robotic arms can accurately place goods on designated locations on shelves along tracks or through joint movements. This precise placement can maximize the use of warehouse space and increase storage density. At the same time, it can also take goods from the shelves to complete the outbound operation, and the whole process is efficient and accurate.

Robotic arms are very critical equipment in the cargo sorting process. In the express sorting center, parcels are transported via conveyor belts, and the robotic arm can sort the parcels to different exit channels based on the destination information or other identification codes on the parcels. It can quickly make judgments and perform sorting actions, and the sorting speed can reach several pieces per second. Its control system obtains parcel information through a visual recognition system or sensor, and then directs the robotic arm to accurately guide the parcel to the correct path.

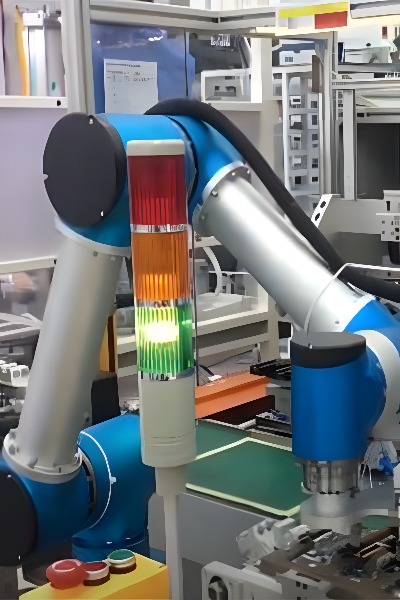

Robotic arms have many vital applications in production lines.

In the production of electronic devices, such as smartphone manufacturing, robotic arms can accurately install tiny electronic components such as chips, resistors, capacitors, etc. on circuit boards. The accuracy of robotic arms can reach the micron level, which is crucial to ensure the performance and quality of electronic devices. For example, the robotic arm can locate the solder joints on the circuit board through the visual recognition system, and then accurately place the chip in the corresponding position, with the error controlled within a very small range, far exceeding the accuracy of manual assembly.

For the assembly of mechanical products, robotic arms are also indispensable. It can install fasteners such as bolts and nuts on parts, and can control the tightening torque to ensure the firmness and consistency of assembly. On the automobile engine production line, the robotic arm is responsible for assembling components such as pistons and connecting rods into the engine block, tightening the bolts according to strict torque requirements, improving assembly quality and efficiency.

In cases where some products need to undergo performance testing, the robotic arm can assist in completing the testing process. For example, on a motor production line, the robotic arm can install the motor on the test equipment, start the test program, and then record the motor's speed, torque and other performance parameters. If the performance parameters do not meet the standards, the robotic arm can sort out the unqualified motors and feed back the relevant data to the production management system so that the production process can be adjusted.

Our Services

1-year after-sales warranty

Software online update

Cooperative partner