Intimate service

Brand-Offical Supplier(BO)

2024 Years

Brand-Offical Supplier(BO)

2024 Years

Company Infomation

Founded in 2012, Sunke is a state-level high-tech enterprise with its own brand. It has subsidiaries in Beijing, Shanghai, Guangzhou, Foshan, Shenzhen and Hangzhou, with nearly 400 employees.

After more than 10 years of development and accumulation, Senke has formed a diversified business model of R & D design, production and manufacturing, system integration, e-commerce, sales and service, and its main products are industrial three defense terminals, industrial computer, industrial tablet computer, touch teaching machine, LCD advertising machine, LCD splicing screen, LED full color screen and other display products. Its products are widely used, covering industrial Internet, Internet of things, artificial intelligence, high-end equipment, commercial display, big data and other national strategic emerging industries and key areas, industrial products and commercial display products in the Internet market market share has been in the forefront of the industry for many years.

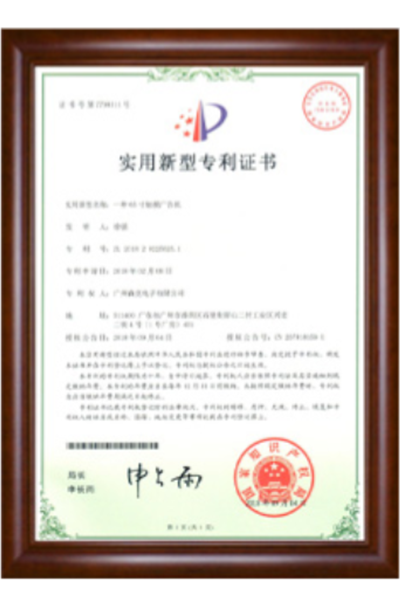

Adhering to the R & D concept of "innovation as vitality", Sunke has established an independent R & D technical team accounting for 20% of the total number of employees, with a mature and forward-looking R & D system, and has more than 100 core hardware and software patented technologies. In 2022, the Shanghai company passed the enterprise certification of specialized new little giant. With its strong hardware and software innovation and iteration ability, Senke has built a solid technical barrier, which has won the high recognition and trust of the domestic and foreign markets, and also made Senke grow into one of the high-tech enterprises with independent core technologies in the field of commercial display in China.

At the same time, based on the three core cities of Beijing, Shanghai and Guangzhou, Sunke has established a production base serving the whole country, with a total construction area of more than 30,000 square meters, and has listed more than 200 series products and laid out more than 3,000 service sites. Products are sold in more than 150 countries and regions around the world, and more than 100,000 cooperative customers. Sunke has always maintained close cooperation with major brand owners and suppliers around the world, based on the forefront of the industry, closely follow the changes of the Internet market, and strive to bring users better product solutions, better product experience and more intimate pre-sales and after-sales service.

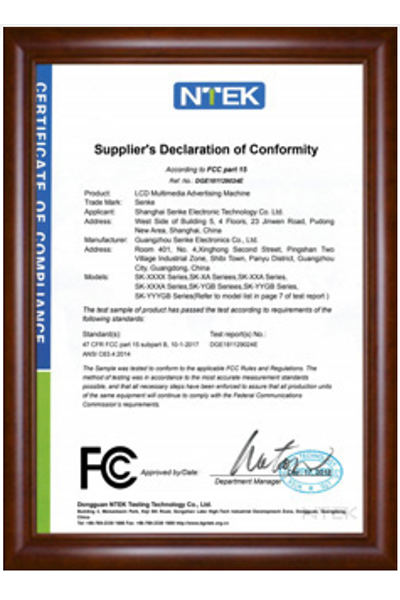

Company Certificate

Company Case

Automatic production line monitoring and control

Production line workers can visually view the real-time status of each device by touching the all-in-one machine. For example, the SMT mounter's placement speed, placement accuracy, nozzle usage and the amount of remaining material are clear at a glance. The touch screen displays the production progress in the form of dynamic graphics and data tables, such as the current number of completed motherboards and estimated completion time. When the equipment is faulty or abnormal, touch the all-in-one machine immediately pop up a striking alarm window, showing the fault code, fault location and possible causes in detail, accompanied by sound prompts, to ensure that the staff can detect and deal with it in the first time.

Technicians can easily switch the monitoring interface of different devices on the integrated machine by touch operation, and gain an in-depth understanding of the parameter changes in each production link. For example, at the reflow welding machine interface, key parameters such as temperature curves in different areas of the furnace and conveyor speed can be viewed, and these parameters can be adjusted in real time to optimize welding results.

CNC machine operation and management

The all-in-one touch machine replaces the traditional CNC machine tool control panel, providing operators with a more intuitive and convenient operation interface. On the touch screen, the key parameters such as the axis position of the machine tool, the current processing speed and tool information are clearly displayed. Operators can easily edit programs, simulate tool paths, and manually control coordinate axes with touch gestures. For example, during program editing, the virtual keyboard and text editing function of the touch all-in-one allows the operator to quickly enter and modify G code instructions, and the correctness of the code can be checked in real time. In the tool path simulation function, the machining path of the tool on the workpiece is displayed in the form of 3D graphics, so that the operator can predict the machining effect in advance and avoid the workpiece scrap caused by program errors.

For complex processing tasks, touch all-in-one supports multi-window display. The operator can view the machining parameters in one window, set the tool compensation in another window, and observe the real-time state of the machine tool in the third window, such as the spindle load, cutting fluid flow, etc., which greatly improves the efficiency and accuracy of the operation.

Machining production line

In the automatic production line of the machining workshop, the industrial touch integrated machine plays the role of core control and monitoring. It is connected to a number of CNC machine tools, automated material transfer systems and inspection equipment. In the process of processing, the screen of the touch machine clearly displays the working state of each machine tool, including real-time parameters such as spindle speed, tool feed, and processing temperature. According to the actual needs, the operator can easily adjust the machining parameters of the machine by touch operation, such as optimizing the cutting speed to improve the processing efficiency or reducing the processing temperature to extend the tool life. When the detection equipment finds that the dimensional accuracy of the machined parts is incorrect, the touch machine immediately sends an alarm, and accurately locates the machine tool and processing process that may have problems, and at the same time calls up the relevant historical processing data, assisting technicians to quickly analyze the cause of the failure, which may be tool wear, machine screw loosening, etc., so as to timely maintenance and adjustment. Ensure the continuous and stable operation of the production line, and effectively improve the quality and production efficiency of the machined products.

Chemical production line

The chemical production line has very high requirements for the control and safety monitoring of the reaction process, and the industrial touch integrated machine has shown its skill here. It is deeply integrated with reactors, piping systems, temperature and pressure sensors, and various automated valves. In the reaction process, the touch machine real-time display of the temperature, pressure, liquid level and chemical reaction process in the reactor key information. The operator can set and adjust the reaction conditions on the touch screen, such as precisely controlling the reaction temperature within a specific range, adjusting the feed speed and flow rate of the material. Once there is an abnormal rise in temperature and pressure during the reaction process, the touch machine not only quickly triggers the alarm system, but also automatically closes the relevant valves and stops the material conveying according to the preset safety procedures to prevent dangerous accidents. At the same time, it records all the data in the production process of each batch of secondary chemical products in detail, including the input of raw materials, reaction time, reaction conditions, etc., providing a complete and reliable data basis for subsequent quality traceability, process optimization and environmental compliance review, ensuring the safety and efficiency of chemical production.

Our Products

Our Services

3C certification

National guarantee