Laser cutting

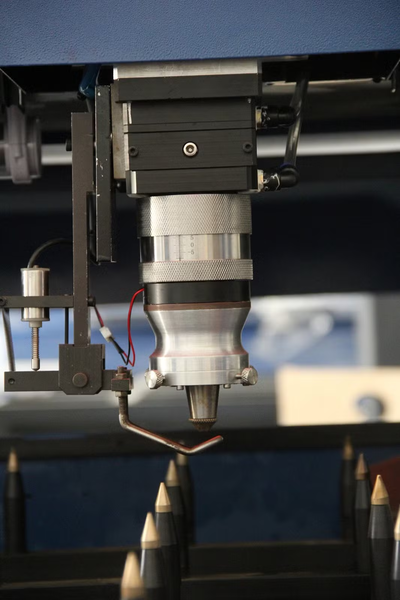

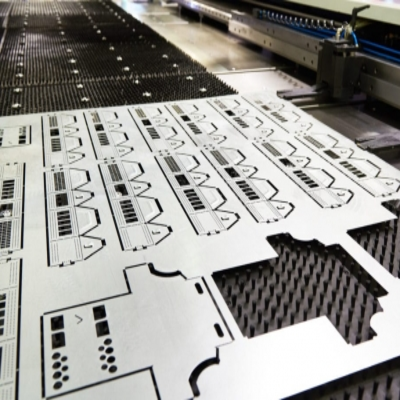

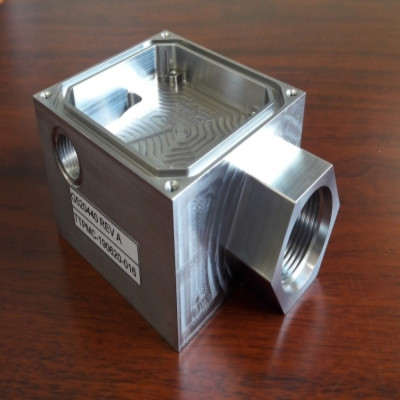

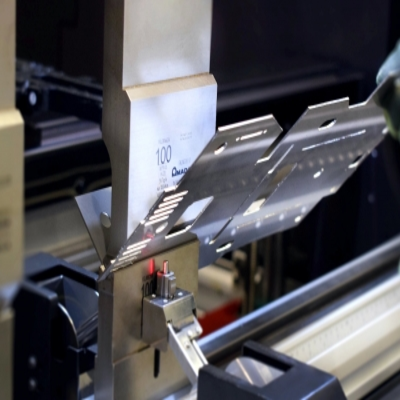

is a precise manufacturing process that uses a high-powered laser to cut or engrave materials like metal, plastic, and wood. The laser beam melts, burns, or vaporizes the material, creating clean and accurate cuts. It's known for its high precision, speed, and ability to cut complex shapes. Laser cutting is computer-controlled, allowing for detailed designs with minimal human intervention. The process produces minimal heat-affected zones, reducing material distortion. It is commonly used in industries like aerospace, automotive, and manufacturing for intricate and custom parts.