24-hour response

Brand-Official Supplier(BO)

5 Years

Brand-Official Supplier(BO)

5 Years

Company Infomation

APRobotics, capitalizing on its skilled and cost-effective workforce in Al, embeddedsystems, and mechatronics, envisions a transformation into an incubator. This incubator is dedicated to crafting state-of-the-artsolutions tailored to address societal challenges in South East Asia, with a particular focus on Vietnam. By adeptly integrating software development, Al core technologies, self-driving capabilities, and strategic collaborations, aims to drive innovation and tackle critical social issues.

Established in 2020, APRobotics aims to develop safe and reliable autonomous solutions to make mobility and transportation safer, more affordable and accessible. As a pioneer leader in autonomous technologies and services in Vietnam, APRobotics has stepped up to the commercial stage. APRobotics offers diverse products and services with Autonomous Mini-bus, Drones, AGV, Assistant Robot, Smart Entrance, and so on, providing smart solutions for smart city, on-demand transport and urban logistics. APRobotics has formed strategic partnerships with leading global OEMs, ensuring that the benefits of autonomous solutions are available to as many people as possible.

To be the leading pioneer in the autonomous technology revolution, empowering the world with safe, efficient, and innovative solutions by 2030.

We aspire to bring together human creativity and artificial intelligence to create a better future, where autonomous things enhance our lives, communities and the planet in meaningful ways.

Company Case

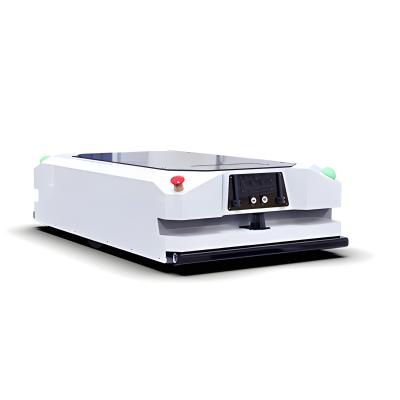

AGV consists of two parts: Smart AGV and Smart tools. Smart AGV is the base that can be moved flexibly according to the digital map and Smart tool is the upper function that can be changed arbitrarily based on usage requirements. These two parts are mechanically linked by a quick-release system, combining functions with central management software. Therefore, it is possible to flexibly use many features of the robot, to improve efficiency and save investment.

Highly accurate 2D map

Smart AGV is equipped with two 2D lidars capable of 360 scanning around the AGV, collecting data about the factory space. From there, build a 2D map for the factory quickly and accurately.

Flexible plan/route setting

The process of transporting goods in the factory is set up on the server management software or the operation panels by the touch screen feature, which is very flexible to easily change the plan/route for the user.

Short implementation time

With an experienced team and complete mastery of AGV's technologies, the quick deployment of Smart AGV, professional and timely maintenance, and little impact on the customer's production plan.

Our Services

Online technical support and software upgrades

1-year warranty

Cooperative partner