GuaranTee supplier (GT)

2025 Years

GuaranTee supplier (GT)

2025 Years

Key process capabilities

Professional engineering and technical team, quickly and accurately matching the most suitable processing equipment, providing fast proofing, small batch processing and large batch production services; perfect quality assurance system and double quality inspection standards, ensuring the delivery of high-quality products to customers within the specified delivery period.

Service industry and technology

Service industry:Automotive industry, aerospace industry, engineering machinery, consumer products, semiconductors, transportation, medical biology, electrical, metal products, measurement and testing, construction and lifting, food industry, chemical industry, telecommunications industry, rubber and plastic industry, packaging/printing, textile industry, oil and gas, etc.

Service technology:Machining, sheet metal, stamping, casting, forging, plastic forming, assembly, mold manufacturing, rapid prototyping, powder metallurgy, spring and wire forming, extrusion, heat treatment, surface treatment, bearings, fasteners, hardware, pumps, valves, joints, etc.

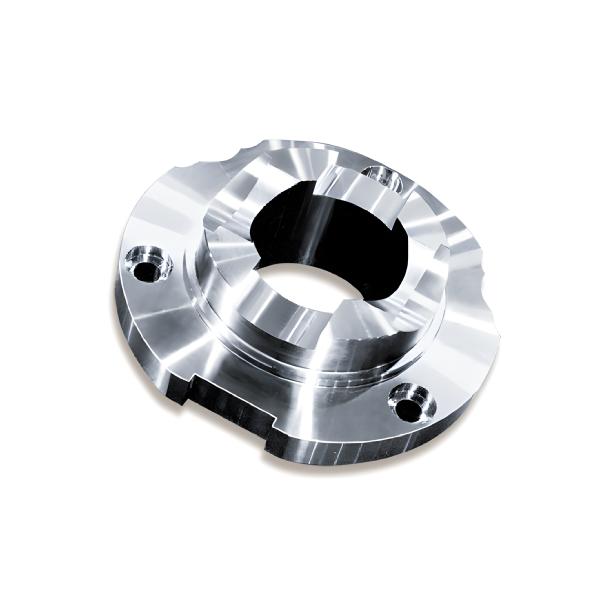

Machining

Main processes:Five-axis machining, boring and milling machine machining, gantry milling machining, CNC milling, turning, automatic turning, gear forming, special machine shaping, EDM

Sheet metal

Main processes:Bending, welding, CNC punching, cutting, structural parts, metal spinning

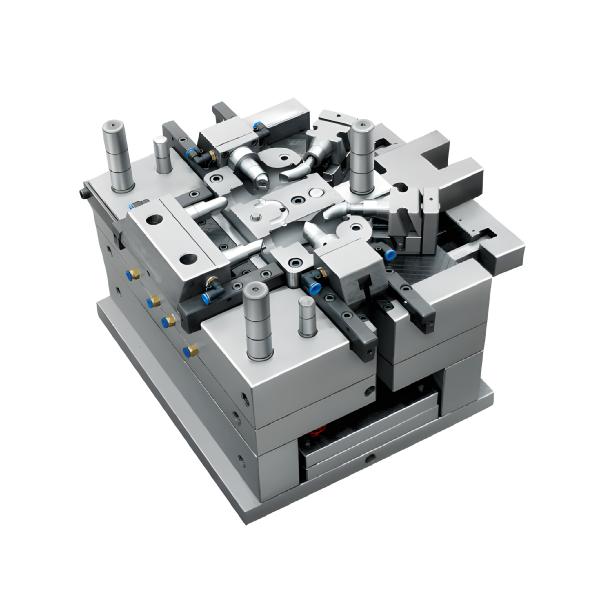

Plastic molding

Main processes:Injection molding, multi-color injection molding, blow molding, compression molding, rotational molding, vacuum molding, rubber product molding

Stamping

Main processes:General stamping, deep drawing, progressive die stamping, precision stamping

Casting

Main processes:Sand casting, die casting, investment casting, lost foam casting, metal mold casting, centrifugal casting

Mold manufacturing

Main processes:Stamping molds, sheet metal molds, injection molds, blow molding molds, extrusion molds, other plastic molding molds

Application

Applied in new technology fields such as automobiles, biomedicine, equipment manufacturing, aerospace, new energy, 5G, smart transportation, wearable devices, etc.

Automobiles

Biomedicine

Equipment manufacturing

Aerospace

New energy

5G

Smart transportation

Wearable devices

Product Case

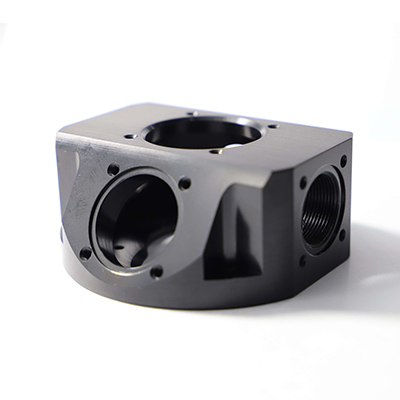

Optical block

Process: CNC machining

Material: 5A05 aluminum

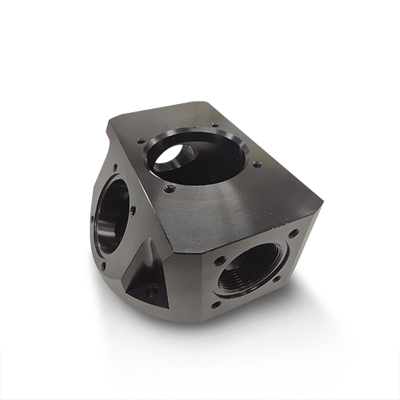

Assembling housing

Laboratory analytical instrument product parts

Observation window

Various oil pipeline pressure observation window product part

Mirror stamping sheet metal parts

Mirror polished sheet metal parts for high-end commercial juicers, food grade 316 material, direct contact with food

Bearings

The product material is bearing steel GCr15, and its main function is to reduce the friction coefficient during operation and ensure its rotation accuracy

Machined parts

Gear products, core components of large drones

Natural gas valve bonnet

Spherical sand casting, machining, drilling and trimming to form the final product

Roller pizza cutter

The roller pizza cutter made of SUS304 material can be used to cut pizza, cake, etc

Company strength

We focus on marketing and sales automation solutions, robotics technology, and tool and component manufacturing businesses. We aim to provide comprehensive support and promote business cooperation within the industry. By utilizing our professional knowledge and resources, we help our members thrive in the era of Manufacturing 4.0.

We specialize in precision parts processing, providing services for the production of molds, spare parts, and special components. Our members have rich technical knowledge and are equipped with the most advanced machining centers, possessing extensive processing capabilities.

We have a wide variety of processing resources and are equipped with the most advanced mechanical equipment to ensure excellent manufacturing capabilities. Our advanced equipment includes the latest five axis machining center from Mazak in Japan, CNC lathes from Mazak in Japan, CNC lathes from Victor, Polugrim, Goodway, and Alpha in Taiwan, CNC machining centers from Hass in the United States, automatic surface grinders from Okamoto in Japan, wire cutting machines from Sodick in Japan, and turn milling composite machines from Okuma in Japan.

We take great pride in the quality of our products and conduct rigorous quality checks and inspections before delivering them to our valued customers. Our professional team ensures that every component meets strict quality standards. By combining advanced mechanical equipment with meticulous attention to detail, we provide the highest quality products that meet and exceed customer expectations.

Quality control

Strict quality inspection standards

Continuously maintain our own quality management system according to international standards

Strictly carry out quality inspection according to customer requirements, and provide material inspection reports, product inspection reports, product and packaging photos, and other quality-related report documents according to customer needs.

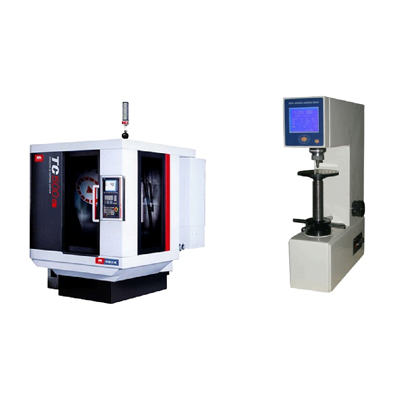

Quality inspection equipment

Quality inspection equipment

Quality inspection equipment

Quality inspection equipment

Quality inspection equipment

Quality inspection equipment

Quality inspection equipment

Quality inspection equipment

What problems do we solve?

Shortened the time of non-standard parts processing and procurement process, with stable delivery time,Ensure quality.

01/Help customers establish a continuous, stable and flexible supply chain

Based on the manufacturing resource library and supply chain team established over the years, we can quickly dispatch high-quality production capacity elements in different industries, establish a stable and efficient supply chain system, and dynamically adjust according to changes in customer needs

02/Ensure production efficiency

We will break down the product into multiple BOMs and distribute them to different core manufacturers for production. Our professional supply chain team will provide training, full process control, and technical support to the manufacturers to ensure production efficiency

03/Transformation from laboratory R&D to factory-manufacturable engineering

Solve the vacuum between R&D enterprises and factory production, standardize laboratory solutions through engineering and process, and transform them into manufacturable products

Email:Service76@ttbridge.com

Address:53, Moo. 9, Talaythong Tower, fl. 8 ,Room no. 808-809, TungSuKla, Si Racha, Chon Buri 20230 Thailand