GuaranTee supplier (GT)

10 Years

GuaranTee supplier (GT)

10 Years

Motion Pioneer joint motors focus on providing high-performance joint motor solutions, covering four core products:

Frameless motors - adopt a housingless design, compact structure, can be directly embedded in the device, achieve high dynamic response and precision control, and are ideal for collaborative robots and medical equipment.

Inner rotor motors - high-speed response, strong adaptability, often used with reducers, suitable for high-speed scenarios such as industrial servos and CNC machine tools.

Outer rotor motors - external rotor design, large torque, excellent heat dissipation, support direct drive applications, widely used in drones, wheel hub drives and automated turntables.

Joint reduction motors - highly integrated design, integrating motors and precision reducers, providing high torque, low backlash transmission, specially optimized for robot joints and automation equipment.

We are committed to providing reliable and efficient motor drive solutions for industrial automation, robotics and high-end equipment!

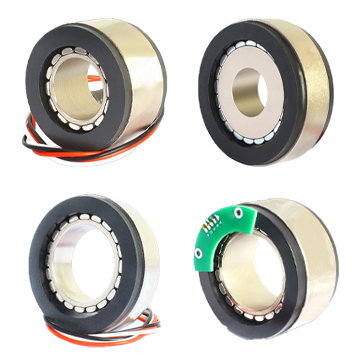

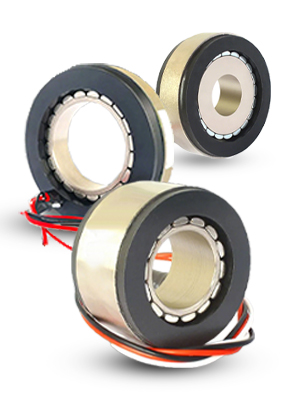

Frameless motor

Omits the traditional housing and has a more compact structure.

Integrated directly into the equipment to reduce transmission components.

High torque density, fast dynamic response, suitable for precision control.

Commonly used in high-precision fields such as robotics, aerospace, etc.

Internal rotor motor

The rotor rotates internally

Excellent high-speed response

Suitable for high speeds

Requires a reducer

Common in industrial servos

We provide industry-leading motor drive solutions to help smart manufacturing and automation upgrades. Here, you will see:

The direct-drive motor series with advanced frameless design achieves ultra-high dynamic response and precise control, perfectly adapting to various high-precision application scenarios

The high-torque outer rotor motor product line shows excellent power density and heat dissipation performance, meeting the continuous operation requirements under harsh working conditions

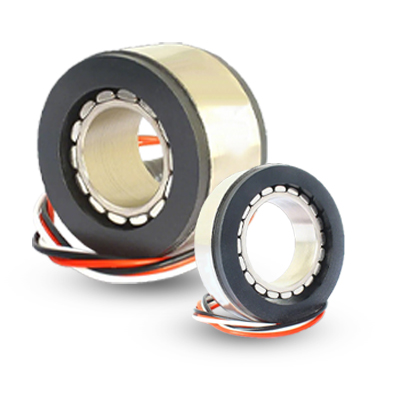

The high-speed inner rotor motor combination, with an intelligent servo system, provides millisecond-level response speed and smooth operation performance

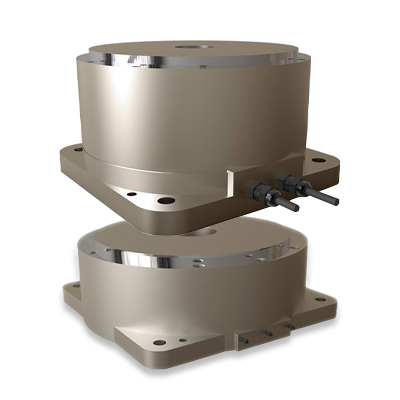

The integrated joint module solution integrates a precision reduction mechanism and a dual feedback system to achieve a convenient experience of ready-to-use

We have selected star products in various power ranges, from compact servos to high-power models. The professional engineer team is ready to provide you with selection suggestions and customized services at any time, and explore the infinite possibilities of intelligent drive together!

Robot joint frameless torque motor U series

Outer diameter (mm): 25-200

Rated torque (Nm): 0.025-13

Rated speed (rpm): 300-4000

Torque parameter (Nm/Arms): 0.01-0.93

Inner rotor DD motor torque motor FI series

Rated torque (Nm): 0.25-320

Rated current (Arms): 2-8

Torque parameter (Nm/Arms): 0.1-45

Rated output power (W): 7.9-2012

External rotor DD motor torque motor FE series

Rated torque (Nm): 1-250

Rated current (Arms): 1.5-7.1

Torque parameter (Nm/Arms): 1.2-29.6

Rated output power (W): 21-1310

SETZ special series/SETZ linear series joint motor

Rated output power (KW): 0.15-3

Bus voltage (V): 48-96

Peak current (A): 10-50

Weight (KG): 0.75-13.5

SETZ70/SETZ90/SETZ120 series small robot joint motor

Rated speed (rpm): 21-2250

Bus voltage (V): 48-72

Rated power (kw): 0.16-1.5

Weight (KG): 0.45-3.9

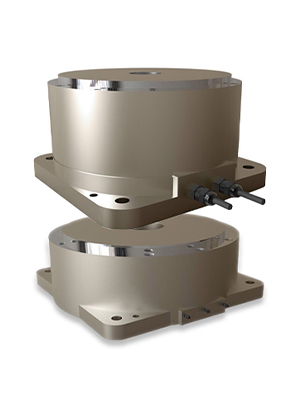

SG series high-efficiency and high-power joint reduction motor

Outer diameter: 78.7~100mm

Rated speed: 48~310rpm

Peak torque: 18~75Nm

Transmission structure: planetary/cycloid pinwheel

Rated voltage: 24-48v

Motion Pioneer joint motor - professional driving future technology! We provide four core motor categories: frameless motor, inner rotor motor, outer rotor motor and joint reduction motor, covering high-performance application scenarios.

Suitable for AGV/AMR wheels to achieve precise movement, hub motors to drive efficient electric vehicles, exoskeleton robots to improve human-machine collaboration, drone gimbals to ensure stable shooting, and active suspension systems to optimize vehicle dynamic performance. With high torque density, low noise and excellent response speed, Motion Pioneer motors provide reliable power solutions for industrial automation, robotics and intelligent transportation, helping innovative technologies to operate efficiently.

AGV/AMR wheels

High-precision control

Compact and efficient

Low noise and long life

Intelligent response

Hub motor (wheel drive motor)

Efficient integration

High torque density

Precise control

Strong environmental adaptability

Motion Pioneer joint motors are widely used in the field of high-end intelligent equipment, including: collaborative robots (high-precision force-controlled joints), exoskeletons/humanoid robots (lightweight high-torque drive), AGV/unmanned vehicles (wheel hub motor direct drive), drone gimbals (ultra-stable anti-shake), active suspension systems (millisecond-level dynamic adjustment), special vehicles (electric wheel hub drive) and precision industrial equipment (semiconductor/CNC machine tool positioning). With high response and modular design, it provides core power solutions for intelligent manufacturing, medical, transportation and military fields, promoting technological innovation and industrial upgrading.

Hub motors are widely used,

Hub motors are used in intelligent robots, agv carts, electric vehicles, electric wheelchairs, special machine tools, printing and inkjet equipment and other equipment, which can improve space utilization, transmission efficiency, positioning and navigation and play an important role.

Benefiting from the growing demand for robots, automation and intelligent manufacturing, integration, lightweight and high torque density have become the trend, and frameless torque motors, direct drive motors and integrated joint motors (such as collaborative robot joints) are widely used. At present, joint motors are widely used in collaborative robots, bionic robots, medical and exoskeleton fields, and will further develop in the direction of high dynamic response, high energy efficiency and intelligence in the future.

Frameless torque motor

Frameless torque motor has compact structure, fast response and large torque, which is suitable for high-precision direct drive scenarios such as robots and aerospace.

Inner rotor

Inner rotor motor has compact structure, high speed and fast response, which is suitable for high-speed drive scenarios such as servo systems and power tools.

Outer rotor

Outer rotor motor has large torque, good heat dissipation and compact structure, which is suitable for high-torque and low-speed scenarios such as drones and wheel hub drives.

SG series high-efficiency and high-power joint reduction motor

High-power joint reduction motor has large torque, high precision and fast response, which is suitable for high-load precision transmission such as robot joints and automation equipment.

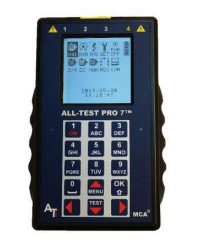

Dongchuang Pioneer shutdown motors always focus on high quality and are equipped with advanced testing equipment to fully control product performance.

In terms of electrical performance, high-precision testers are used to verify insulation, withstand voltage and current stability

Mechanical performance is tested for durability, vibration and torque to ensure reliable operation

The appearance and size are tested by optical measuring instruments and three-coordinates to meet strict tolerance standards

Other performance such as temperature rise and noise are strictly screened by professional equipment

We use a scientific and rigorous quality control system to ensure that each motor has excellent performance, safety and durability, and provide customers with trustworthy products.

Coordinate measuring machine

Noise tester

Motor fault detector

Motor comprehensive tester

Industrial endoscope

Insulation resistance tester

Baker DX series tester

Dynamometer

Power analyzer

Hall sensor tester

Withstand voltage tester

Withstand voltage tester

Dongchuang Pioneer specializes in providing high-precision joint motors and drive solutions, suitable for robots, automation equipment, medical machinery and other fields. Support customized design, provide selection guidance, technical debugging and after-sales maintenance services to ensure efficient and stable operation. Reliable quality, high cost performance, help you upgrade your smart equipment!

Customer needs - one-on-one consultation by a professional team, a variety of models to choose from, accurately matching application scenarios.

Technical support - free parameter debugging, installation guidance and troubleshooting to ensure efficient operation of the equipment.

Secure payment - international security certification of platform accounts, and financial security throughout the transaction.

On-time delivery - real-time monitoring of production progress, delivery before the promised delivery date, and giving the corresponding delivery order number

Logistics tracking - provide end-to-end full-process tracking logistics services. You can accurately understand the location, status, and estimated arrival time of the goods.

After-sales service - within 12 months of the arrival of the goods, we provide repair costs caused by product quality problems. If it is out of warranty, we can provide customers with accessories replacement services, and the relevant overseas shipping costs shall be borne by the buyer.

24-hour response

Technical support

Secure payment

On-time delivery

Logistics tracking

After-sales service

Email:service78@ttbridge.com

Address:Ruida Road, High-tech Zone, Zhengzhou City, Henan Province