One-to-one online customer service

Self operated store

1 Years

Self operated store

1 Years

Company Infomation

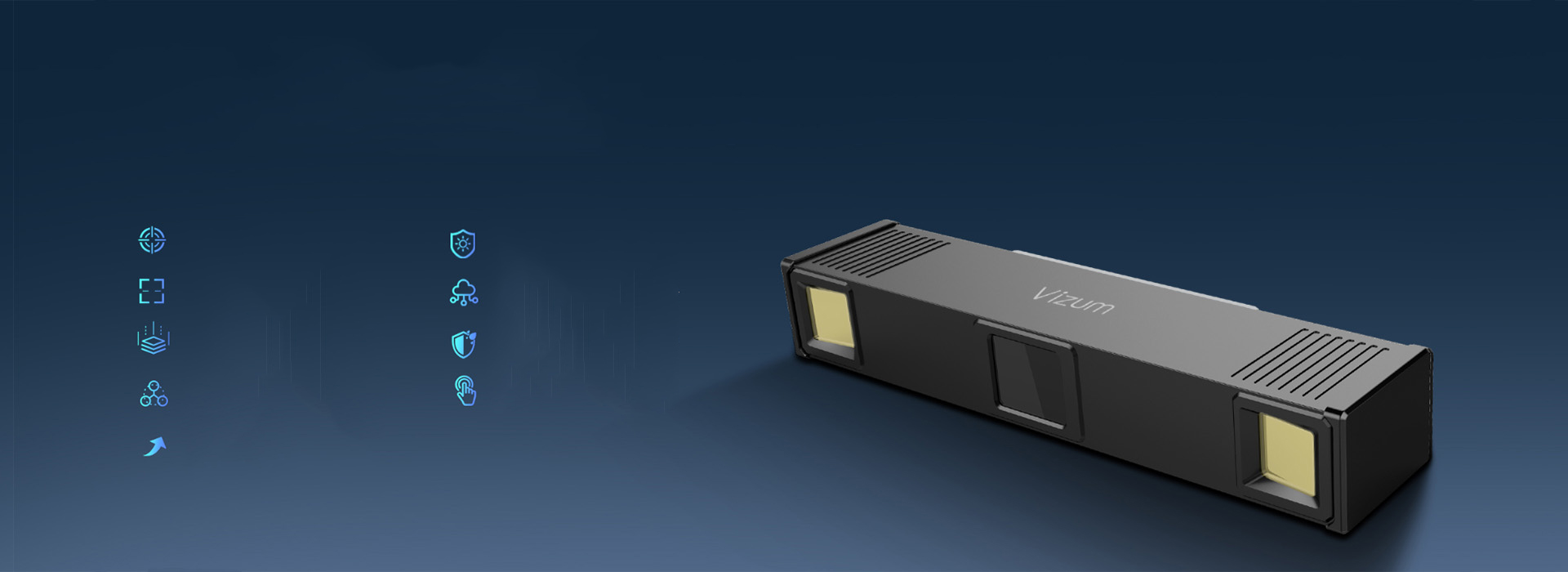

Beijing Vizum Intelligent Technology Co., Ltd.

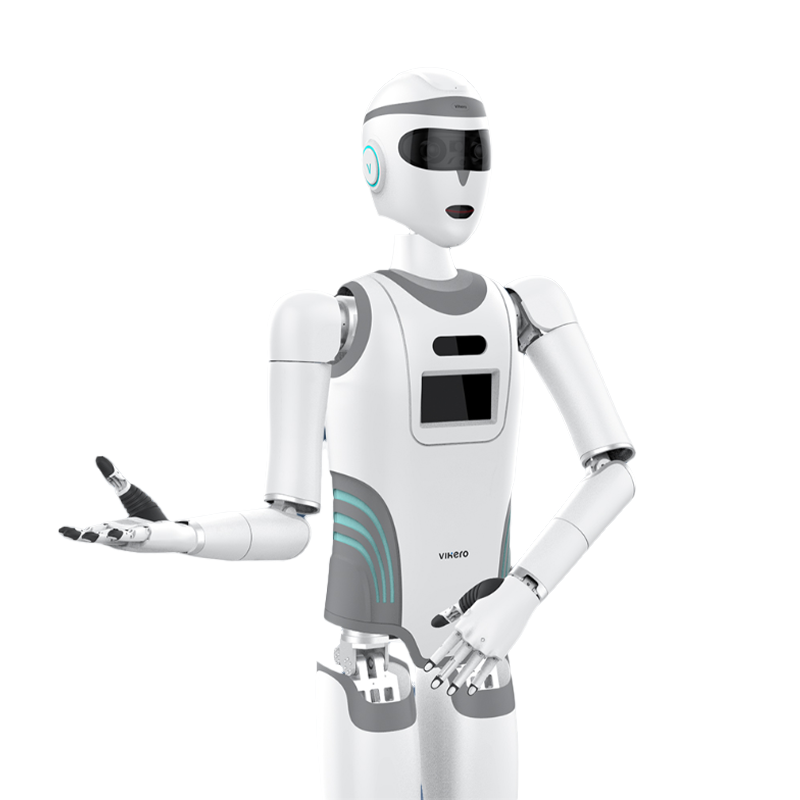

Beijing Vizum Intelligent Technology Co., Ltd. was founded in 2016. It is a high-tech artificial intelligence company focusing on the research, development, production and application of stereoscopic intelligent vision systems and intelligent humanoid robots. It is a national high-tech enterprise and a specialized and innovative small and medium-sized enterprise in Beijing. The company has an overall solution for 3D stereoscopic intelligent cameras and a complete production line for intelligent robots, and has formed a full industry value chain integrating independent core algorithms, core software, core hardware and industry system solutions. At present, more than 150 software and hardware technology patents and more than 70 invention patents have been applied for and authorized.

The company's independently developed 3D stereo vision cameras have been successfully used in industrial automation, intelligent welding, palletizing and grabbing, smart mining, steel metallurgy, railways, agriculture and other industries. It has more than 300 implemented intelligent vision development projects, and its customers include more than 50 domestic and foreign listed companies and central enterprises.

Vizum Intelligent will continue to be committed to promoting the innovation of industrial-grade stereoscopic vision and humanoid robot technology, bringing more efficient and intelligent solutions to the industry. We will work hand in hand with our customers to play an important role in the country's independent innovation and intelligent manufacturing.

Company Certificate

Company Case

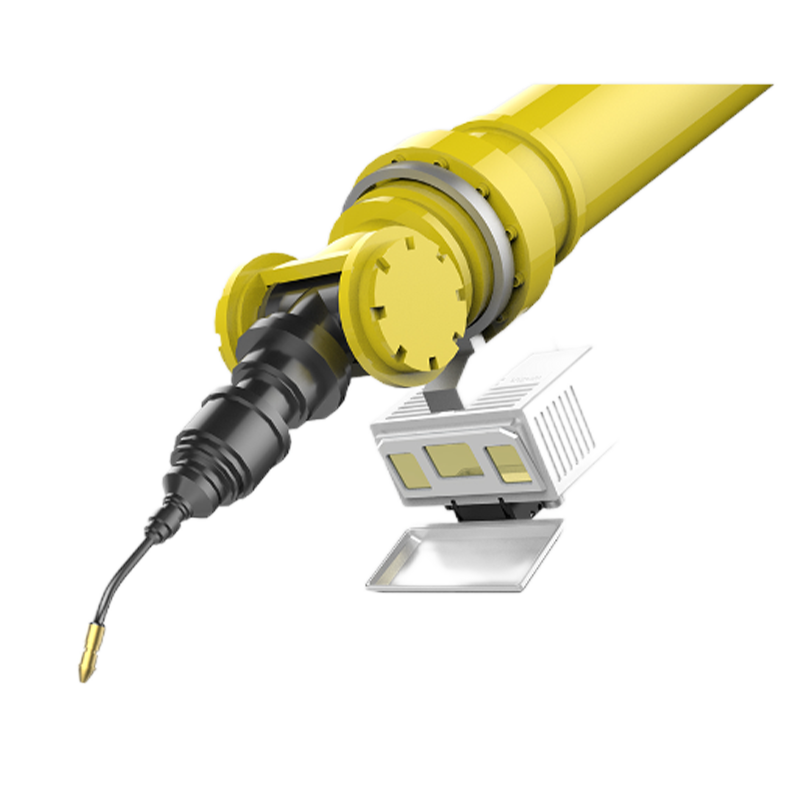

3D vision intelligent welding guidance application platform (Tiger platform)

The 3D vision intelligent welding guidance application platform (Tiger Platform) is based on the Zhiguangyan stereo camera with independent intellectual property rights. It uses the camera's large field of view, large depth of field, and high precision. Only one camera is needed to complete long-distance and large-range workpiece recognition and coarse positioning, close-range scanning weld extraction, and has point, line, surface recognition and contour recognition functions.

Vizum Intelligent provides customers with free welding detection and welding extraction standard communication protocols. In order to facilitate users' rapid implementation and integrated development, Vizum Intelligent has also developed 3D visual intelligent welding guidance management software, which has the functions of importing workpiece design model operations and automatic matching of welding libraries, one-click generation of welding programs, 3D model visualization of weld extraction, remote parameter debugging, etc. Welding users only need a small amount of development to meet the application needs of weld extraction.

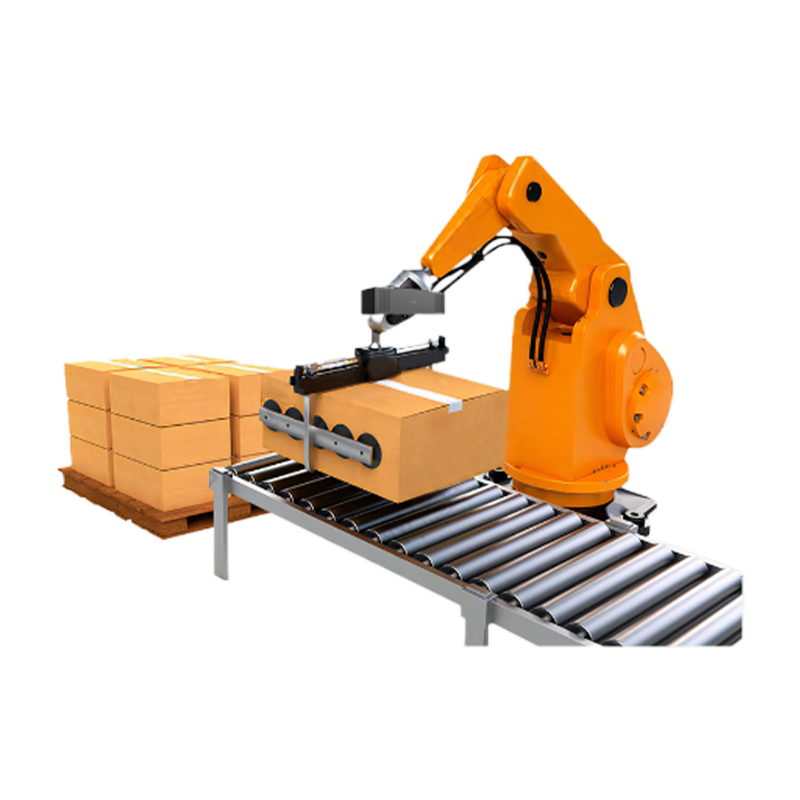

3D visual positioning and grasping application platform

The 3D vision positioning and grasping application platform (Flying Tiger platform) uses highly modular system integration and takes 3D stereoscopic vision technology as the core to visually encapsulate and display image perception, image cognition, stereo modeling, positioning guidance, posture detection, hand-eye calibration, interface docking, signal triggering and other functions and algorithm modules. Users can call the required functional modules from the algorithm library provided in the platform software according to their own needs, and then complete the work tasks independently by operating the industrial 3D camera.

Conveyor flow volume monitoring system

The conveyor flow volume monitoring system adopts the stereoscopic vision technology system independently developed by Vizum Intelligent. It can collect volume big data of objects on the dynamic conveyor in real time through the Zhiguangyan stereo camera. There is no need to modify the on-site environment of the conveyor. The camera can be fixed on the top of the conveyor to complete the on-site layout. The system can be used for a variety of intelligent application transformations such as conveyor speed control, production big data management, and outbound flow control. It is suitable for flow volume monitoring applications on moving conveyors in the fields of coal, mining, salt, stone, cement, logistics, and agriculture.

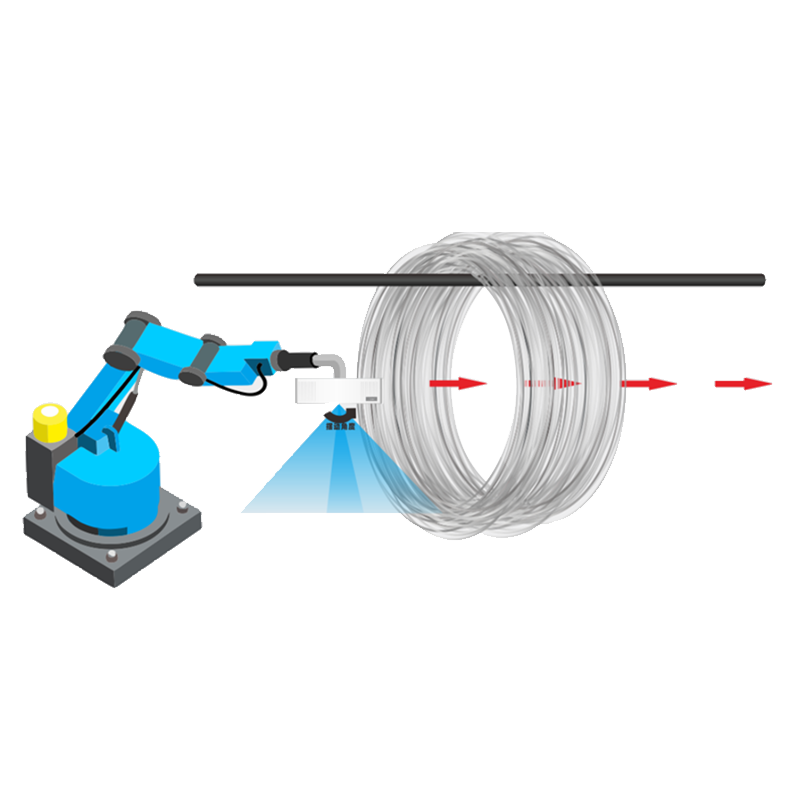

High-line tag positioning system

The high-line label positioning system is an automated labeling solution based on stereo vision detection technology. The core adopts the binocular principle for positioning guidance. It can accurately and quickly locate the labeling points that meet the width and depth of the wire rod, guide the labeling robot, and accurately hang the label. It is suitable for various coil-shaped labeling applications such as rebar and steel wire. It has high work efficiency, can withstand high temperatures, is not afraid of changes in natural light, and is not afraid of different thicknesses of straps and other scene challenges.

Our Products

Our Services

Lightning Delivery

Pre-sales and after-sales technical support