Safety inspection

T1

11 Years

T1

11 Years

Company Infomation

Shenzhen Uwant Technology Co., Ltd. was established in 2014, specializing in the research and development, production, sales, and service of robot products such as unmanned moving vehicles (AGVs), intelligent delivery vehicles, intelligent motion chassis (ROS), intelligent inspection vehicles, and autonomous mobile robots (AMR). It is a steadily growing national high-tech enterprise. With the support of high-tech such as artificial intelligence, cloud computing, big data, robotics, 5G communication, and the Internet of Things, intelligent robots will increasingly appear in various production and life scenarios in the context of "Made in China 2025". In line with the trend of the times, Youwangte Technology attaches great importance to the research and development of innovative technologies and has obtained more than 50 patented technologies. It has successively launched intelligent moving vehicle products and overall systems using navigation methods such as laser, vision, and magnetic strips. Driven by innovation, it continuously pursues excellent quality and enhances user experience. We strive to practice: Uwant, only do what you want!

Quality objective: on-site service after retail;

Development goal: To make life more comfortable;

Business philosophy: Focus on the profession you specialize in, and focus on what you specialize in;

Development motivation: continuously serving and meeting customer needs;

Cultural philosophy: Diligent and innovative, pragmatic and efficient, optimistic and enterprising.

Company Certificate

Company Case

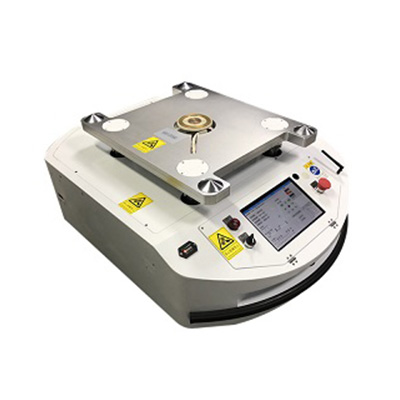

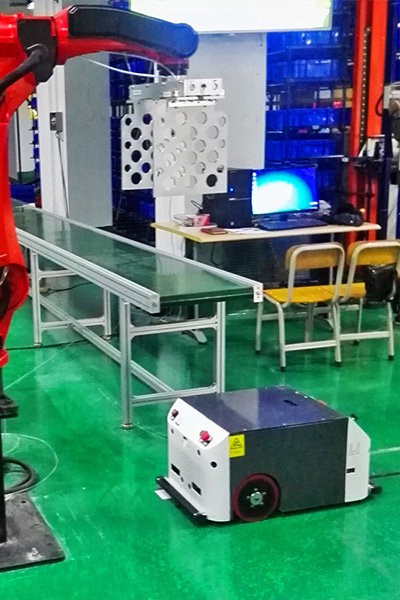

Towed automatic transport vehicle AGV

The intelligent unmanned automatic transporter produced by Uwant Technology has flexible load forms, and can carry loads on the back, tow the tail, tug on the ground, lift the ground, transfer loads with rollers, etc. It has fast speed, small size, large load capacity, and can rotate in place, making it easy to turn around.

Main parameters

Size: 650*450*350mm

Tail traction load: 500kg

Navigation mode: magnetic navigation

Operation direction: one-way automatic

Fork Road: Supports automatic selection of 3 fork roads

Site identification: Industrial RFID, in the form of numbered ID

Function identification: Industrial RFID, can realize stop, acceleration, deceleration, waiting, path selection, etc.

Control mode: automatic operation, manual operation (wired\wireless)

Software support: Windows client, mobile client, vehicle display

Load form: tail traction, latent traction, top load

Battery life: 8 hours

Secondary development: Support, open related software and hardware interfaces

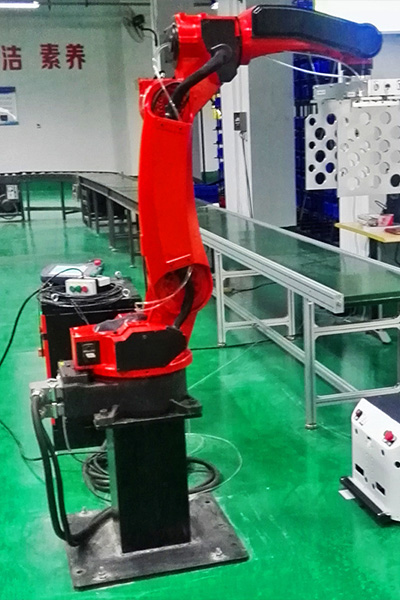

Lurking traction AGV car

The triggering of the task command is completed by the tablet computer, and the computer is integrated with relevant program software;

Navigation method: magnetic strip traction AGV

Use the shortest route to reach the designated stop point, and use a combination of arc turns and right-angle turns during driving;

Design the route to achieve the best, less detours, and keep the delivery frequency stable and efficient; ensure that there are no mistakes in loading and unloading materials, and there is no need to wait for a long time at the loading and unloading points

Operation safety: Five-layer external standard protection

A safety protection device consisting of radar + infrared obstacle sensor (adjustable detection distance) is used to ensure operation safety. The car brakes and stops when obstacles are detected within the range of 0.02 to 1.5 meters.

The overall system adopts three-stage detection: one stage for early warning, two stages for deceleration, and three stages for braking. When an obstacle is detected entering the safety warning area, the AGV decelerates and issues a warning sound; when an obstacle is detected entering the danger zone, the AGV automatically stops and automatically resumes operation after the obstacle is removed.

Our Products

Our Services

Warehouse transportation

Factory Floor