Research and Development

Leading R&D capabilities

T1

11 Years

T1

11 Years

Wanshsin Seikou (Hunan) Co.,Ltd.

WANSHSIN SEIKOU (HUNAN) CO., LTD. (hereafter referred to as “WANSHSIN”) is professional gear motor manufacturer integrating in R&D, production ,sales and service. WANSHSIN mainly manufactures high-precision gear motors which are widely used in robots, machine tools, solid garages and other industrial automation. As a gear motor manufacturer and complete intelligent automation solutions provider, WANSHSIN introduced advanced import processing equipment, adopted advanced technology, to meet the strict high quality requirement for worldwide customers. All efforts made WANSHSIN a reputable and high quality brand in gear motor industry.

To satisfy domestic and overseas customers'requirement, WANSHSIN fully opened the international strategic layout and determined to follow the path of building a strong enterprise for a stronger country. And WANSHSIN pays more attention to the quality improvement of current products and development of new products, and successively introduced high-tech talents, both domestic and international. In the future, WANSHSIN will continuously keep the faith that “Committed to building a world-class electromechanical brand” and strive to the development of the industrial intelligent system of the world.

WANSHSIN Intelligent Manufacturing|The first double-decker bus parking project application case in China

As the first double-decker bus parking lot put into operation in China, the Huaihe Road Bus Parking Lot Project of Qingdao Zhenqing Bus Group was provided with a parking transmission solution by WANSHSIN. All its parking mechanical equipment is equipped with WANSHSIN's four series of reduction motors. While improving its automation and parking efficiency, it greatly saves the space required for parking multiple bus lines and effectively improves the surrounding static traffic environment.

Advantages of WANSHSIN Parking Garage Special Reducer: 1. F-class insulation: made of 100% copper wire, the motor has a long life; 2. High output shaft strength: special steel heating treatment process, the strength is greatly improved; 3. Long-term use, maintenance-free: the grease adopts a special optimized formula, long-term use and maintenance-free; 4. 6-level precision, extremely low noise: the gear set is designed with customized software, and is processed with imported gear grinding machines and secondary fine scraping equipment, with a precision level of 6 and extremely low operating noise; 5. Exquisite appearance and corrosion resistance: powder plus electrostatic automated assembly line spraying is adopted, and the powder is a corrosion-resistant material to prevent aging and falling off; 6. Good safety performance, specially customized torque is increased to 3 times; 7. Gears and other core components have excellent performance: the gears are made of 20CrMnTi plus carburizing process, with excellent wear resistance and bending performance, avoiding the risk of broken shafts due to instantaneous impact.

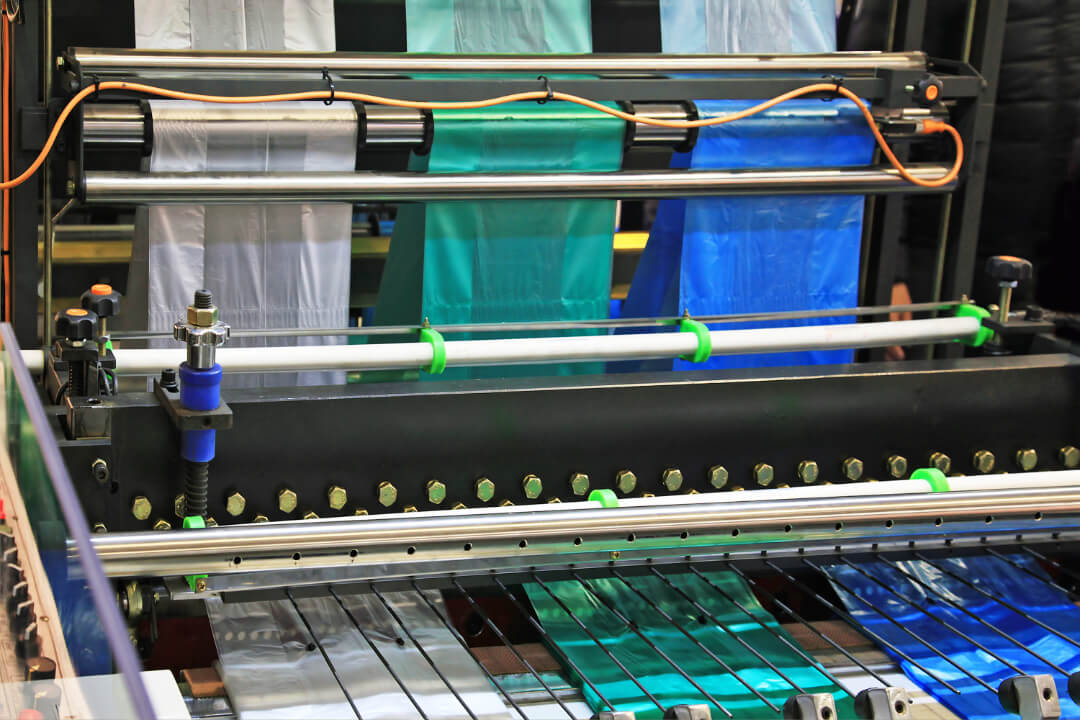

Plastic Machinery

The design and manufacturing level of the reducer is directly related to the technical level and service life of the plastic machinery, and affects the efficiency and energy consumption of producing plastic products.

Warehousing and Logistics

WANSHSIN products are widely used in warehousing logistics sorting systems. Warehouse robots have penetrated into more complex logistics operations such as sorting and picking, bringing logistics automation to a new level of intelligence.

Research and Development

Leading R&D capabilities

Manufacture

Advanced Manufacturing Capabilities

Serve

Fast service capability