Product Description

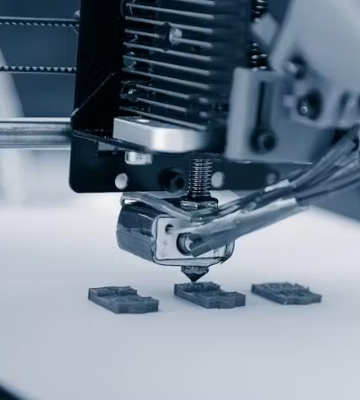

As a trusted manufacturer, we offer specialized customized casting parts services to meet the unique needs of our clients. With a focus on precision and quality, we utilize advanced casting techniques to produce components tailored to your specifications. Whether it's for small-scale or large-volume production, we work closely with you to ensure each part meets the highest standards of performance, durability, and efficiency. Our commitment is to deliver reliable, cost-effective solutions that support your business goals and enhance your product's functionality.

Product parameters

| Investment casting (lost wax casting) | Stainless steel casting Alloy steel casting Carbon steel casting Bronze and Brass casting Aluminum casting |

| Sand casting | Clay wet sand type Resin sand casting Water glass sand casting |

| Machining | Drilling, Reaming and tapping CNC Turning machining CNC Milling machining |

| Heat treatment | Annealing Solution Normalizing Tempering Quenching Induction hardening Hardening and tempering |

| Surface treatment | Manual polishing Electro-polishing Electro-plating Power coating Tumbling |

Custom Process

Upload your design

Design analysis

Start production

Receive your parts

Process Type

CNC Machining

Die Casting

3D Printing

Material

Stainless steel

Aluminum

Titanium

Brass

Additional processes

Heat Treatment: Heat treatment is a critical process used to enhance the mechanical properties of cast parts, including strength, hardness, and durability. By carefully heating and cooling the cast components in controlled environments, we can adjust their microstructure to achieve the desired performance characteristics. This process not only improves the overall quality of the parts but also ensures they are more resistant to wear, corrosion, and stress, making them ideal for demanding applications in various industries. Whether you're seeking improved toughness, increased hardness, or better fatigue resistance, our heat treatment services provide the optimal solution for your casting needs.

Anodizing:

Enhancing corrosion resistance and appearance, often used for aluminum parts.

Anodizing is an electrochemical process that enhances the corrosion resistance and appearance of metal parts, particularly aluminum. By forming a protective oxide layer on the surface, anodizing increases the material's durability, making it more resistant to wear, scratches, and environmental factors. In addition to improving corrosion resistance, anodizing also allows for the customization of the part’s aesthetic, offering a range of colors and finishes. This process is ideal for applications in industries such as aerospace, automotive, and electronics, where both performance and appearance are critical.