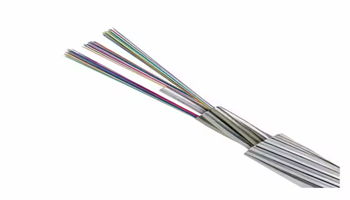

Product Description

The JST cable electrical wiring harness is a high-quality, reliable solution for connecting electrical components. It features durable, insulated wires that ensure safe and stable power transmission. Designed with precision, the harness uses JST connectors for easy, secure connections. Ideal for a wide range of applications, including automotive, industrial, and electronics. The harness is available in custom lengths and configurations to meet specific project needs. Its compact design enhances space efficiency while ensuring high performance and longevity.

Product parameters

| List | Details |

|---|---|

| Brand Name | electrical wiring harness JST cable |

| Application | Electronic |

| Model Number | customized cable assembly |

| Color | custom |

| Material | Copper/pa66/pbt/high Temp |

| Packaging Details | standard export international box package |

| Single package size: | 1X1X1 cm |

| Single gross weight: | 0.200 kg |

Custom Process

1. send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Machining part wiring

involves creating electrical connections in a mechanical component. It starts with designing the layout of wiring paths, ensuring proper insulation and clearance. The wiring is then carefully routed through the part, with attention to securing and protecting it from damage. Connections are made using terminals or soldering, followed by testing for functionality. Finally, the part undergoes quality checks to verify electrical performance and safety standards.

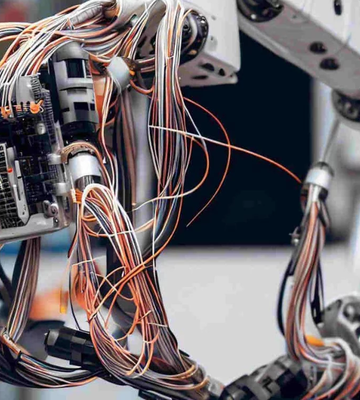

Robot part wiring

begins with designing the wiring schematic based on the robot’s components and functions. Wires are routed through the robot’s structure, ensuring minimal interference with movement. Each connection is securely terminated with connectors or soldering. The wiring is then insulated and protected from mechanical stress, heat, and environmental factors. Finally, all electrical systems are tested for proper functionality and safety compliance.

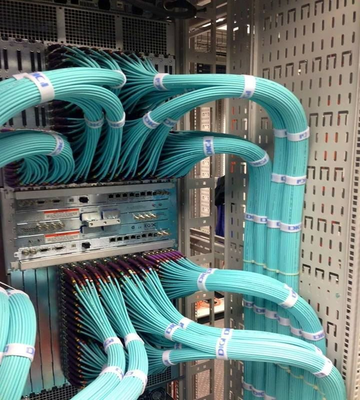

Electrical part wiring

starts with planning the circuit design and determining wire specifications. Wires are cut, stripped, and routed to connect the components as per the design. Connections are made securely using terminals, connectors, or soldering, ensuring proper insulation. The wiring is organized to prevent interference and potential damage. Finally, the electrical system is tested for continuity, functionality, and safety compliance.

Material

Copper

Nickel

Aluminum

Processing capability

The processing capability of the electrical wiring harness JST cable is defined by its versatility, precision, and reliability in various applications. It can handle a wide range of current and voltage specifications, making it suitable for different industries like automotive, robotics, and consumer electronics. The cables are designed for efficient power transmission with minimal signal loss. The JST connectors ensure secure, reliable connections that can withstand vibrations and environmental conditions.

Additional processes

The harness can be customized with varying wire gauges, lengths, and configurations to fit specific system requirements. It supports multiple termination methods, such as crimping, soldering, or press-fitting, depending on the application needs. The manufacturing process includes high-precision wire stripping, soldering, and assembly, ensuring consistent quality.

Furthermore, the harness is built to endure mechanical stresses, temperature fluctuations, and exposure to moisture, chemicals, and UV light. Its compact design enables space optimization, while its modular nature allows for easy installation and maintenance. It’s also compatible with automated assembly processes, enhancing production efficiency. This processing capability makes the JST wiring harness ideal for high-demand, long-lasting applications.