Product Description

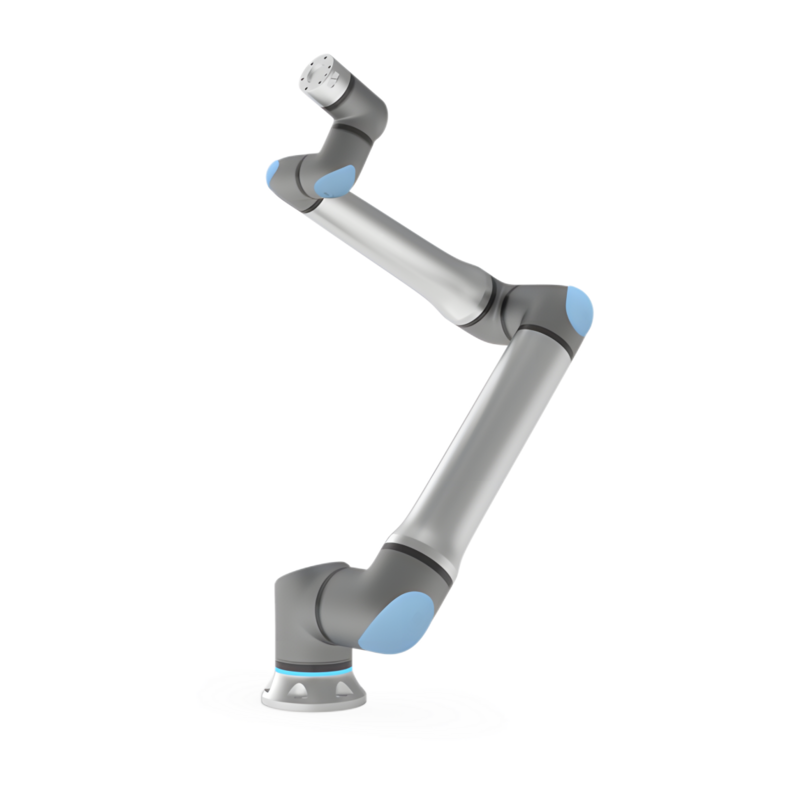

The Collaborative Robotic Arm (Cobot) is an advanced, user-friendly robotic solution designed to work safely and efficiently alongside human operators in industrial environments. Engineered for precision, flexibility, and ease of integration, this robotic arm is ideal for tasks such as assembly, packaging, material handling, inspection, and machine tending.

| Industry | Application Task | Description | Cobot Benefits |

| Automotive | Parts Assembly | Assemble small components like sensors, connectors, or control modules. | High precision, reduces manual fatigue, consistent quality. |

| Machine Tending | Load and unload CNC machines, presses, or injection molding machines. | Operates continuously, frees human workers for higher-level tasks. | |

| Inspection | Visual or sensor-based inspection of parts for defects. | Increased accuracy, real-time quality control. | |

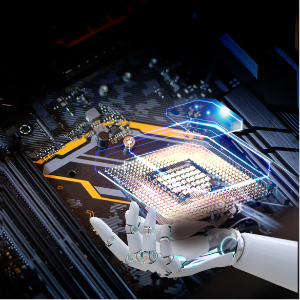

| Electronics | PCB Handling & Soldering | Place and solder delicate components on printed circuit boards. | Delicate handling, improves throughput and precision. |

| Screwdriving | Automated screw insertion in devices or components. | Consistent torque application, minimizes assembly errors. | |

| Metal & Machining | Welding Assistance | Precise arc, spot, or laser welding on metal parts. | Consistent welds, reduces exposure to hazardous conditions. |

| Deburring & Polishing | Remove burrs and polish machined metal parts. | Improves product finish, works around the clock. | |

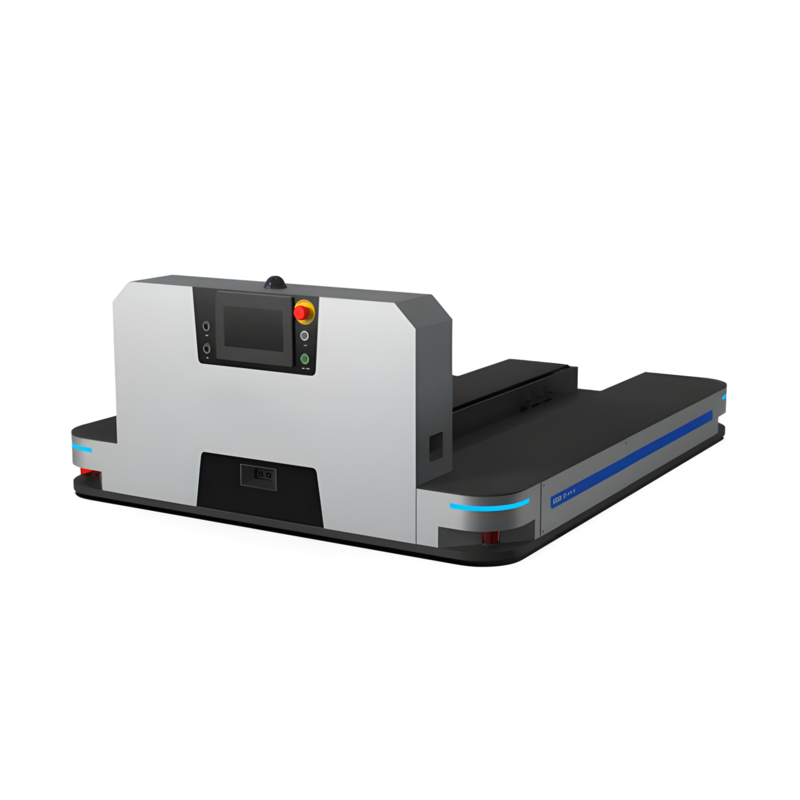

| Logistics & Warehousing | Order Picking | Select and retrieve items from shelves or bins. | Enhances speed, reduces picking errors. |

| Box Erecting & Sealing | Automatically set up and seal shipping boxes. | Speeds up packaging, reduces manual labor |

Product Features

Human-Centric Design: Equipped with intelligent sensors and force-limiting technology, the arm safely collaborates with humans without the need for extensive safety barriers.

Intuitive Programming: Drag-and-drop interface and hand-guided teaching allow for quick setup and reprogramming with minimal technical expertise.

High Precision & Repeatability: Achieves exceptional accuracy and repeatable motion for demanding industrial applications.

Flexible Deployment: Lightweight and compact design makes it easy to relocate and adapt to different tasks and workstations.

Scalable Integration: Compatible with a wide range of end-effectors, vision systems, and industrial protocols for seamless integration into existing workflows.

Structure Diagram

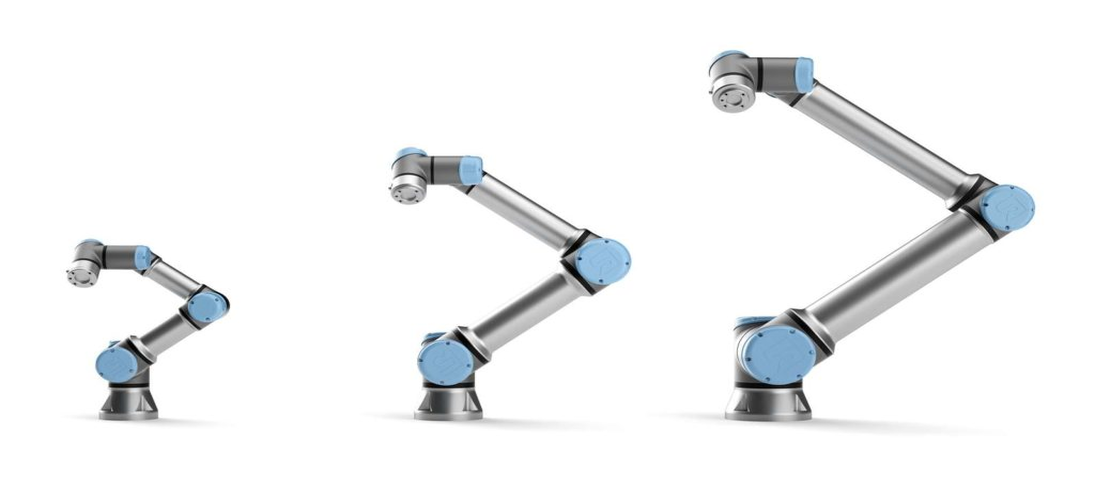

Product parameters

| Parameter | Specification | Parameter | Specification |

| Degrees of Freedom (DoF) | 6 (Optional: 7 for enhanced flexibility) | Power Supply | 100–240V AC, 50/60Hz, or 24V DC (depending on mode |

| Payload Capacity | 5 kg – 15 kg (model-dependent) | Power Consumption | ~150W–350W (average) |

| Reach | 800 mm – 1300 mm | Communication Interfaces | Ethernet, Modbus TCP, RS-485, Digital I/O, USB |

| Repeatability | ±0.02 mm – ±0.05 mm | Programming Interface | Touchscreen Pendant, PC Software, API (Python, ROS, etc.) |

| Joint Speed | Up to 180°/sec (varies by joint and model) | Safety Features | Force & torque sensors, speed limiting, emergency stop |

| End-Effector Speed | Up to 1 m/s | Operating Temperature | 0°C to 50°C (32°F to 122°F) |

| Weight | 20 kg – 35 kg | Ingress Protection | IP54 – IP67 (depending on model and environment) |

Customer Case

Automotive – Machine Tending

Electronics – Small Parts Assembly

Food & Beverage – Packaging Automation

Company Information

FAQ

Q: What makes a robot "collaborative"?

A: A collaborative robot (cobot) is designed to work safely alongside humans without safety cages. It uses sensors, force control, and built-in safety features to detect contact and prevent injuries.

Q: What kind of tasks can a cobot perform?

A: Cobots can handle a variety of tasks including assembly, packaging, palletizing, machine tending, quality inspection, and even welding, depending on the payload and tool attached.

Q: Do I need programming skills to use a cobot?

A: Not necessarily. Most modern cobots have intuitive interfaces with drag-and-drop or hand-guided programming, allowing operators with little or no coding experience to set up tasks.

Q: Are cobots suitable for small and medium-sized enterprises (SMEs)?

A: Yes, cobots are ideal for SMEs due to their low footprint, ease of use, and fast ROI. They can be deployed quickly and reprogrammed easily for different tasks.

Q: How safe are cobots to work with?

A: Very safe. Cobots comply with international safety standards (like ISO/TS 15066) and come with safety features like force-limited joints, speed restrictions, and emergency stop buttons.