Product Description

The AGV with Robotic Arm is a state-of-the-art mobile automation solution designed to streamline material handling, pick-and-place operations, and collaborative tasks in industrial environments. Combining autonomous navigation with a high-precision robotic manipulator, this system enhances productivity, reduces manual labor, and improves workplace safety.

Benefits:

Reduces labor costs and improves operational efficiency

Enhances accuracy and repeatability in handling delicate or complex tasks

Promotes a safer work environment by minimizing human-robot interaction risks

Easily reprogrammable for different workflows and tasks

| Industry | Application Area | Specific Tasks |

| Automotive | Assembly Line Automation | Part picking and placement, engine component handling, door/glass installation |

| Intralogistics | Transport of parts between workstations, machine loading/unloading | |

| Electronics | PCB Assembly | Precise component placement, board transfer between SMT machines |

| Product Testing | Automatic placement of products for testing stations | |

| Inventory Management | Moving and sorting sensitive components | |

| Metal & Machining | CNC Machine Tending | Loading/unloading metal parts, chip removal |

| Tool Handling | Precise transport and placement of heavy or sharp tools | |

| Aerospace | Component Assembly | Handling of lightweight composite or metallic parts |

| Quality Inspection | Positioning of parts for visual or automated inspection |

Product Features

Autonomous Navigation:

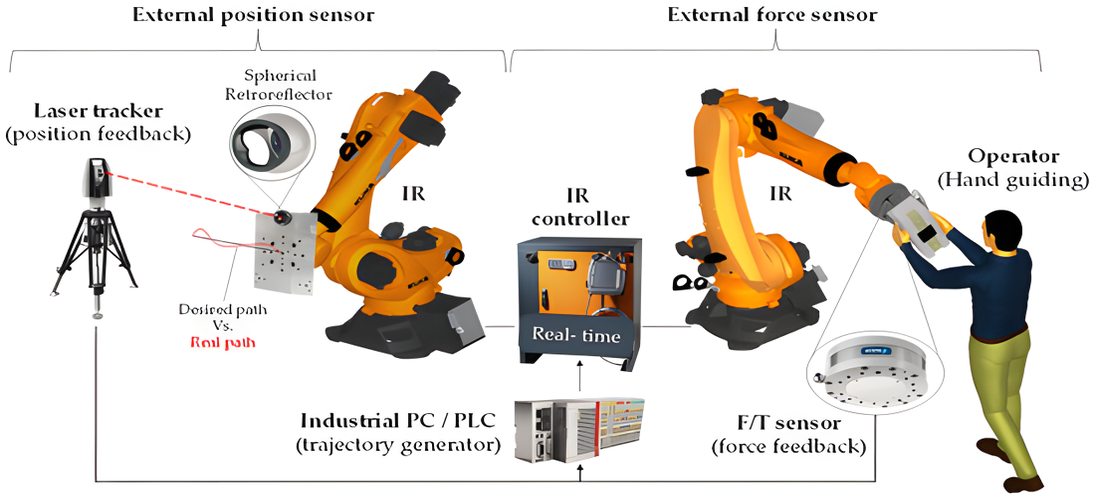

Equipped with advanced LiDAR, vision sensors, and SLAM (Simultaneous Localization and Mapping) technology, the AGV navigates complex industrial layouts with precision and safety.Integrated Robotic Arm:

A 6-axis robotic arm with a high degree of freedom enables precise handling, assembly, and sorting tasks. Payload capacities vary from 5 kg to 20 kg depending on the model.Versatile Task Capabilities:

Ideal for tasks such as bin picking, machine tending, material transfer, loading/unloading, and packaging within manufacturing, warehousing, and logistics operations.

Modular Design:

Customizable arm configurations, end effectors (grippers, suction cups, etc.), and AGV platforms to meet specific application requirements.Smart Control System:

Includes onboard AI-driven task scheduling, real-time obstacle avoidance, and remote monitoring through an intuitive HMI or integration with MES/ERP systems.Safety Compliance:

Designed in accordance with ISO 3691-4 and ISO 10218-1 standards, featuring emergency stop buttons, safety-rated laser scanners, and visual/audible alerts.Battery and Charging:

Long-life lithium-ion battery with automatic or manual charging options. Supports opportunity charging for 24/7 operations.

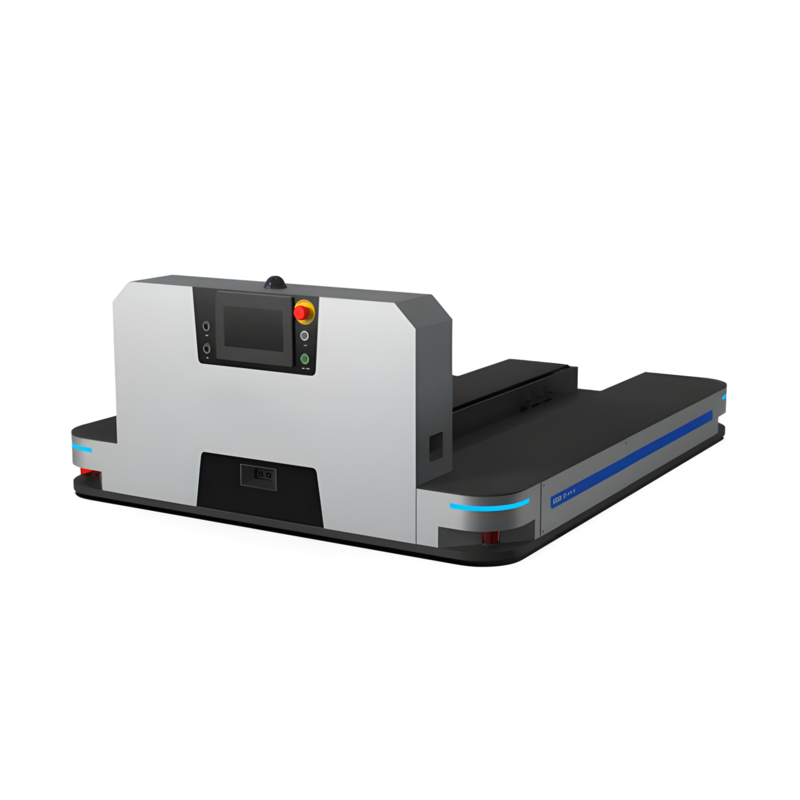

Structure Diagram

Product parameters

| Parameter | Specification |

| Dimensions (L × W × H) | 1200 mm × 800 mm × 400 mm |

| Payload Capacity (AGV Base) | 200 – 1000 kg (depending on model) |

| Max Speed | 1.2 – 2.0 m/s |

| Navigation Method | SLAM / QR Code / Magnetic / Vision / Hybrid |

| Drive Type | Differential / Omni-directional |

| Battery Type | Lithium-ion, 48V, 60Ah – 120Ah |

| Battery Life | 6 – 12 hours (continuous use) |

| Charging Time | 1.5 – 2.5 hours (auto/manual charging) |

| Obstacle Detection | 2D/3D LiDAR, Ultrasonic Sensors, Bumper Sensors |

Customer Case

Automotive Industry

Electronics Industry

Pharmaceutical Industry

FAQ

| QUESTION | ANSWER |

| What is the difference between a standard AGV and an AGV with a robotic arm? | A standard AGV is designed solely for autonomous transport of goods or materials. An AGV with a robotic arm adds a manipulator (robot arm) that can perform tasks such as picking, placing, loading, and assembling — enabling end-to-end automation without human intervention |

| What safety measures are in place for AGVs with robotic arms? | These systems are equipped with multiple safety features, including:

|

| Can AGVs with arms work alongside human workers? | Yes. Many AGV-arm systems are designed to be collaborative (cobot-based), with features like force-limited joints, soft grippers, and safety-rated controls. They can safely work near or with humans in shared spaces, especially in logistics, warehousing, and light assembly environments. |

| How is the AGV with robotic arm controlled and programmed? | They can be controlled via:

|

| What are the typical maintenance requirements? | AGVs with robotic arms require:

|