T1

7 Years

T1

7 Years

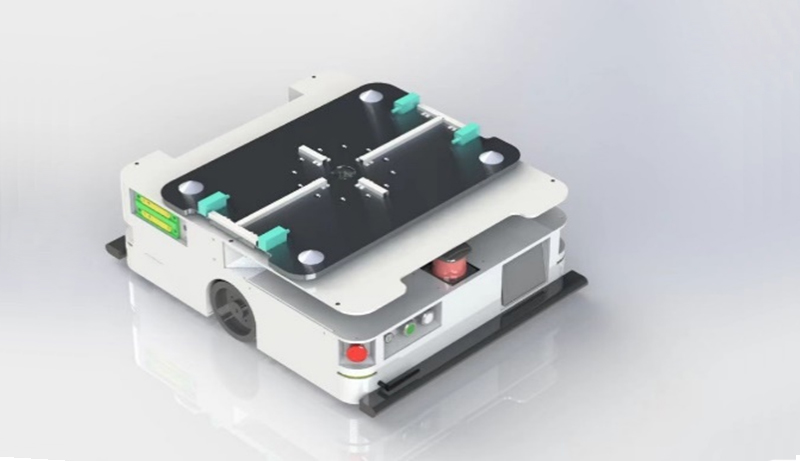

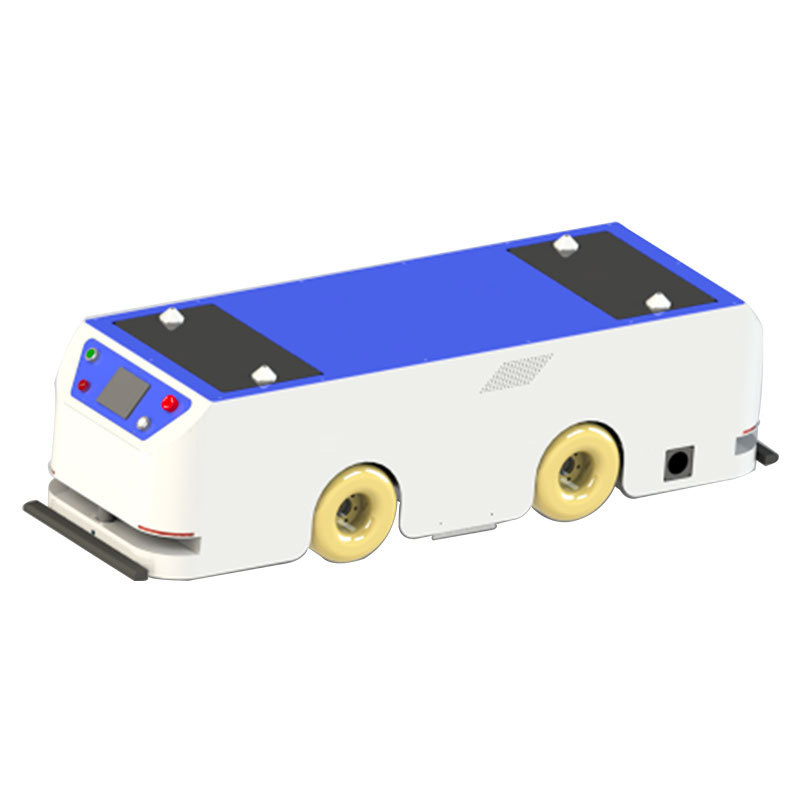

Lifting AGV——J-200CJ-365

Lifting AGV Industrial Equipment Warehouse Logistics Small Intelligent AGV Automatic Guided Vehicle

- Size:L810*W630*H297.5

- Load:200KG

- Deadweight:120KG

- Speed:40m/min

- Battery life:8 hours

- Hill-crossing capability:≤3°

USD: 99999

ablity:Monthly Output200

- Product Description

- Product Params

Product Description

Lifting Series——J-200CJ-365

Product description

| Load | 200KG |

| Deadweight | 120KG |

| Size | L810*W630*H297.5 |

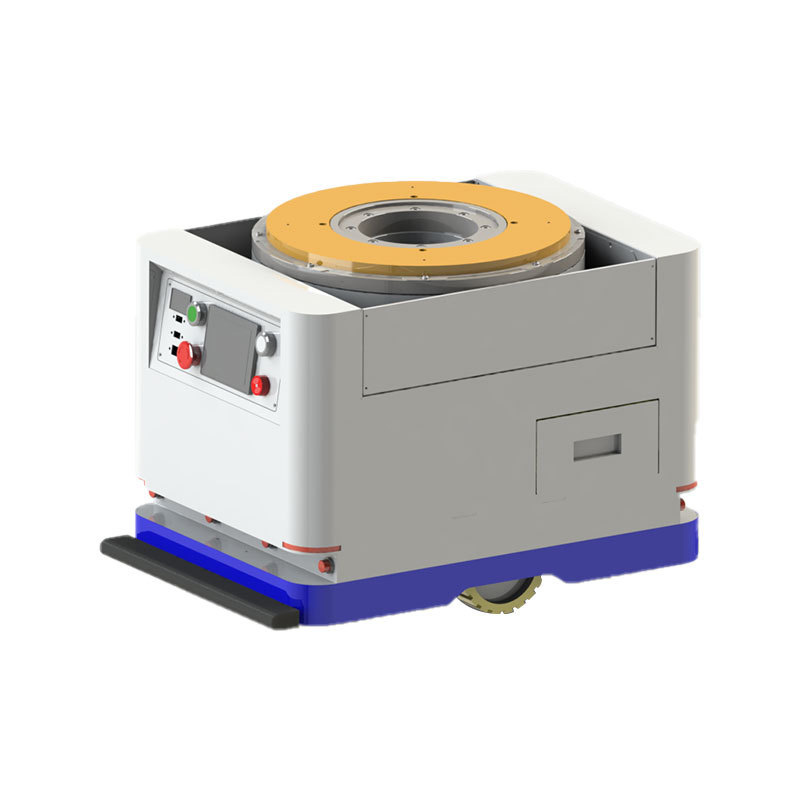

| Lifting stroke | 50mm (with relative rotation) |

| Lifting method | Screw lifting |

| Accuracy | ±10mm |

| Speed | 40m/min |

| Battery Type | Lithium battery 48V 20AH (lithium iron phosphate) |

| Battery life | 8 hours |

| Security | Photoelectric + sound and light + edge touch |

| Communication method | WIFI/optical communication/433 (optional) |

| Power supply | Automatic charging/battery replacement/wireless charging (optional) |

| Navigation | Magnetic navigation/QR code navigation/laser navigation (optional, different navigation systems have different appearances) |

| HMI | 4.3-inch touch screen |

| Usage Environment | Indoors, the ground is oil-free, water-free, and has no slope |

| Motor function | Forward, backward, rotate on the spot (magnetic navigation can make arc turns) |

| Drive mode | Dual wheel differential |

| Hill-crossing capability | ≤3° |

| Wheel Material | Polyurethane |

Navigation Introduction

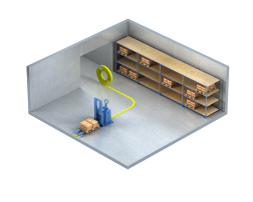

| Magnetic stripe navigation The magnetic strip is used for navigation. AGV reads the magnetic strip to continuously correct the left and right deviations during operation; (the route that the AGV will take must be affixed) |

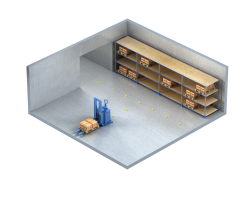

| QR code + inertial navigation The QR code is used for navigation and site identification. A QR code is posted every 1 meter. A gyroscope is installed inside the AGV. The AGV automatically corrects its left and right deviations every meter it walks. The AGV reads the QR code that requires docking, turning, and action, and the AGV starts to execute the action. Each QR code is a unique label; |

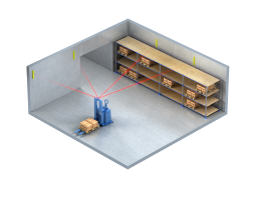

| Slam Laser Navigation The AGV is equipped with a single-line laser head to scan the surrounding environment and record it, forming a 2D map in the AGV's internal controller. Engineers plan the AGV's route and the stops on the 2D map. During the AGV's operation, the laser head scans the surrounding environment in real time and compares it with the 2D map in the controller to correct the operation deviation and the stops that need to be made. |

Recommended products

Lifting 2000KG laser AGV car

Lifting laser AGV car load capacity 2000KG laser navigation steering wheel flat car intelligent automation car

collect:0

Lifting AGV600KG AGV-McLun

Lifting AGV trolley with a load capacity of 600KG, a handling robot, a logistics handling vehicle with a stable structure, an intelligent unmanned vehicle

collect:0

Lift and rotate 100KGAGV

Lifting and rotating AGV trolley 100KG warehouse logistics intelligent unmanned transport vehicle with stable structure and automatic lifting

collect:0