Product Description

Precision planetary reducers have high transmission efficiency, advanced manufacturing technology and optimized gear meshing design, which reduces energy loss during transmission. In the long-term operation, this high transmission efficiency not only means lower energy consumption, but also effectively reduces the operating cost of the equipment and improves the economy of the entire system. Whether it is a continuously operating industrial production line or a special equipment that works intermittently, it can benefit from its efficient transmission.

Product parameters

| Specification | Series | Reduction ratio | MYCR060 | MYCR090 | MYCR142 | |

|---|---|---|---|---|---|---|

| rated output moment | Nm | 1 | 3 | 55 | 130 | 342 |

| 4 | 50 | 140 | 542 | |||

| 5 | 60 | 160 | 650 | |||

| 6 | 55 | 150 | 600 | |||

| 7 | 50 | 140 | 550 | |||

| 8 | 50 | 140 | 542 | |||

| 10 | 60 | 160 | 650 | |||

| 14 | 50 | 140 | 550 | |||

| 20 | 40 | 100 | 450 | |||

| 2 | 12 | 55 | 130 | 342 | ||

| 15 | 55 | 130 | 342 | |||

| 20 | 50 | 140 | 542 | |||

| 25 | 60 | 160 | 650 | |||

| 30 | 55 | 130 | 342 | |||

| 35 | 60 | 160 | 650 | |||

| 40 | 50 | 140 | 542 | |||

| 50 | 60 | 160 | 650 | |||

| 60 | 55 | 150 | 600 | |||

| 70 | 60 | 160 | 650 | |||

| 80 | 50 | 140 | 542 | |||

| 100 | 60 | 160 | 650 | |||

| 120 | 150 | 600 | ||||

| 140 | 一 | 140 | 550 | |||

| 160 | 120 | 500 | ||||

| 200 | 一 | 100 | 450 | |||

| Maximum output moment | Nm | 1,2 | 3~200 | 3 times rated output moment | ||

| Rated input speed | rpm | 1,2 | 3~200 | 5,000 | 4,000 | 3,000 |

| Maximum input speed | rpm | 1,2 | 3~200 | 10,000 | 8,000 | 6,000 |

| Back clearance | arcmin | 1 | 3~20 | ≤13 | ≤13 | ≤13 |

| 2 | 12~200 | ≤15 | ≤15 | ≤15 | ||

| Torsional rigidity | Nm/arcmin | 1,2 | 3~200 | 7 | 14 | 50 |

| Allowable radial force | N | 1,2 | 3~200 | 1,530 | 3,250 | 9,400 |

| Allowable axial force | N | 1,2 | 3~200 | 630 | 1,300 | 4,000 |

| Allowable axial force | N | 1,2 | 3~200 | 765 | 1,625 | 4,700 |

| Service life | hr | 1,2 | 3~200 | |||

| Efficiency | % | 1 | 3~20 | |||

| 2 | 12~200 | |||||

| Weight | kg | 1 | 3~20 | 2.1 | 6.4 | 24.5 |

| 2 | 12~200 | 2.5 | 7.8 | 27.5 | ||

| Use temperature | ℃ | 1,2 | 3~200 | -10℃~+90℃ | ||

| lubricating | 1,2 | 3~200 | Synthetic lubricating grease | |||

| Protection level | 1,2 | 3~200 | IP65 | |||

| Installation direction | 1,2 | 3~200 | Arbitrary direction | |||

| Noise value (n₁=3000rpm) | dB | 1,2 | 3~200 | ≤63 | ≤65 | ≤70 |

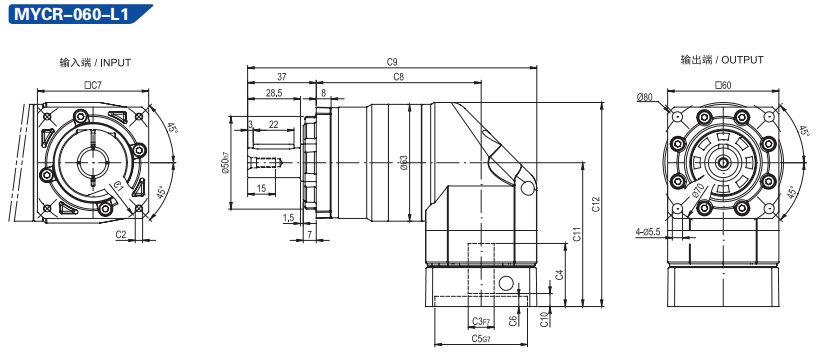

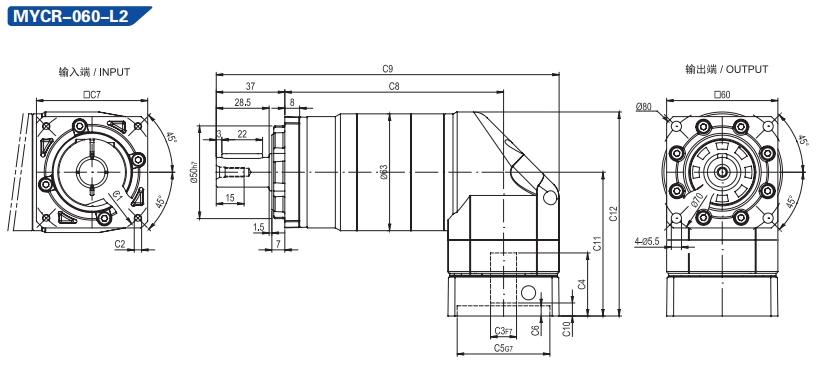

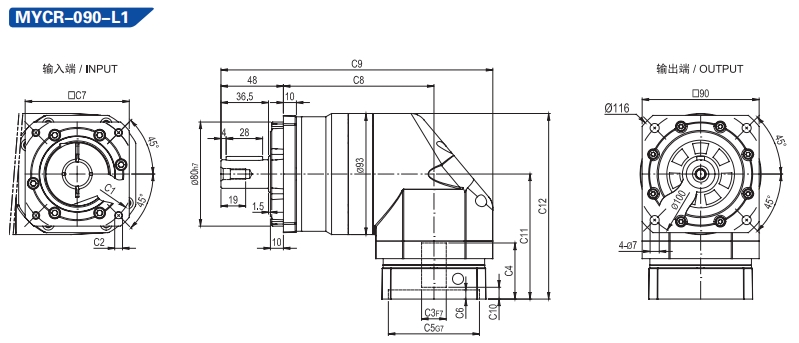

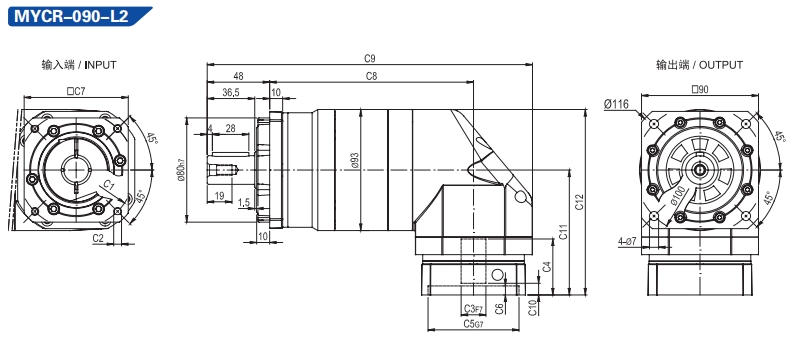

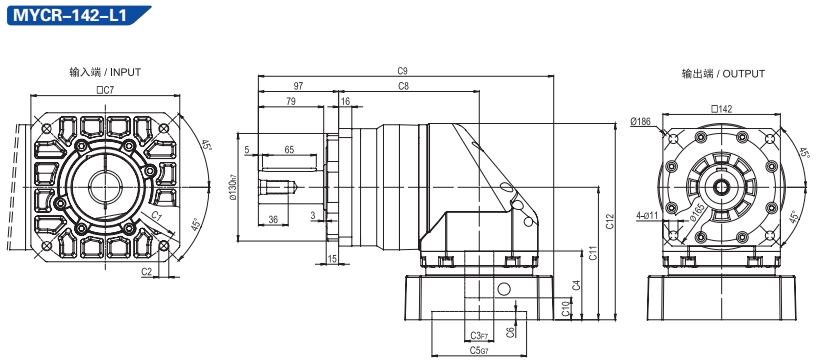

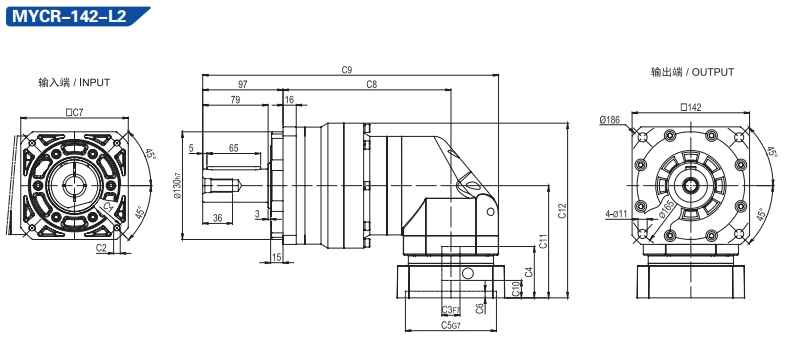

Output shaft diameter

| Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MYCR-060-L1 | ∅66.7 | 4-M4x12 | ∅8 | 33 | ∅38.1 | 5.5 | 60 | 89 | 156 | 7 | 77.5 | 107.5 |

| ∅70 | 4-M4x12,4-M5x12 | ∅11,∅14 | 33 | ∅50 | 5.5 | 60 | 89 | 156 | 7 | 77.5 | 107.5 | |

| ∅90 | 4-M5x15,4-M6x15 | ∅19 | 42 | ∅70 | 7 | 80 | 89 | 166 | 9 | 87 | 119 | |

| MYCR-060-L2 | ∅66.7 | 4-M4x12 | ∅8 | 34 | ∅38.1 | 5.5 | 60 | 118 | 185 | 7 | 77.5 | 107.5 |

| ∅70 | 4-M4x12,4-M5x12 | ∅11,∅14 | 34 | ∅50 | 5.5 | 60 | 118 | 185 | 7 | 77.5 | 107.5 | |

| ∅90 | 4-M5x15,4-M6x15 | ∅19 | 42 | ∅70 | 7 | 80 | 118 | 195 | 9 | 87 | 119 |

| Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MYCR-090-L1 | ∅90 | 4-M5x15,4-M6x15 | ∅19 | 44 | ∅70 | 7 | 80 | 116 | 209 | 9 | 96 | 142.5 |

| ∅100 | 4-M6x15 | ∅16,∅19 | 44 | ∅80 | 7 | 86 | 116 | 209 | 9 | 96 | 142.5 | |

| ∅115 | 4-M8x20 | ∅19,∅22,∅24 | 56.5 | ∅95 | 10 | 100 | 116 | 214 | 17.5 | 108.5 | 155 | |

| ∅145 | 4-M8x20 | ∅19,∅22,∅24 | 60 | ∅110 | 8 | 130 | 116 | 229 | 21 | 112 | 158.5 | |

| MYCR-090-L2 | ∅90 | 4-M5x15,4-M6x15 | ∅19 | 44 | ∅70 | 7 | 80 | 157 | 250 | 9 | 96 | 142.5 |

| ∅100 | 4-M6x15 | ∅16,∅19 | 44 | ∅80 | 7 | 86 | 157 | 250 | 9 | 96 | 142.5 | |

| ∅115 | 4-M8x20 | ∅19,∅22,∅24 | 56.5 | ∅95 | 10 | 100 | 157 | 255 | 17.5 | 108.5 | 155 | |

| ∅145 | 4-M8x20 | ∅19,∅22,∅24 | 60 | ∅110 | 8 | 130 | 157 | 270 | 21 | 112 | 158.5 |

| Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MYCR-142-L1 | ∅145 | 4-M8x20 | ∅22,∅24 | 72 | ∅110 | 10 | 130 | 170 | 338 | 20.5 | 149 | 226 |

| ∅200 | 4-M12x30 | ∅35 | 82 | ∅114.3 | 10 | 180 | 170 | 357 | 26.5 | 160 | 237 | |

| MYCR-142-L2 | ∅145 | 4-M8x20 | ∅19,∅22,∅24 | 62 | ∅110 | 8 | 130 | 203 | 365 | 21 | 135.5 | 211 |

| ∅200 | 4-M12x30 | ∅35 | 82 | ∅114.3 | 10 | 180 | 203 | 390 | 28 | 152.5 | 228 |

*C1-C7 are the dimensions of the metric standard motor connection plate, which can be customized according to customer requirements.

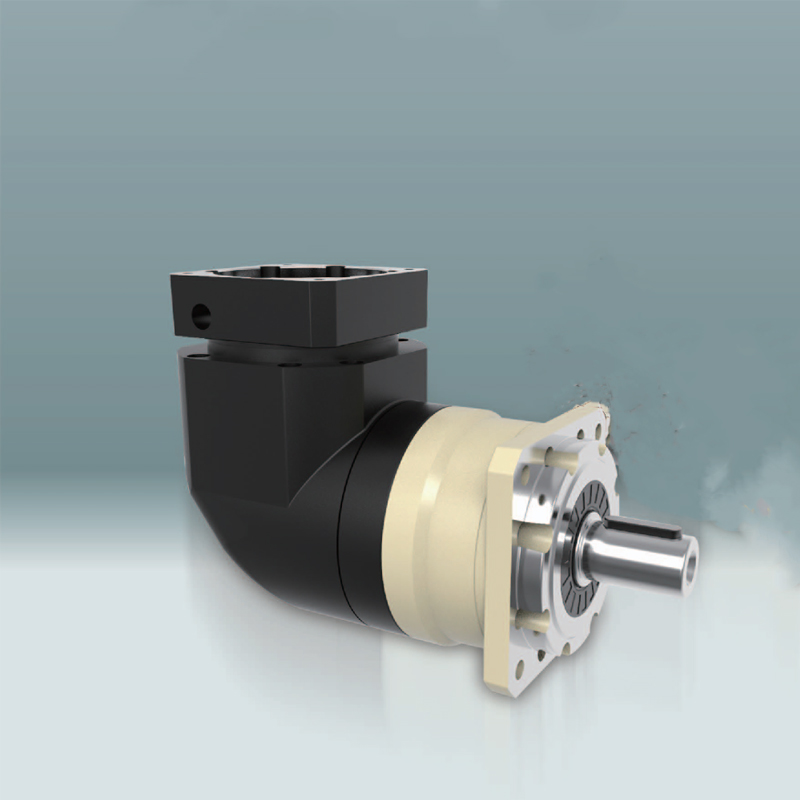

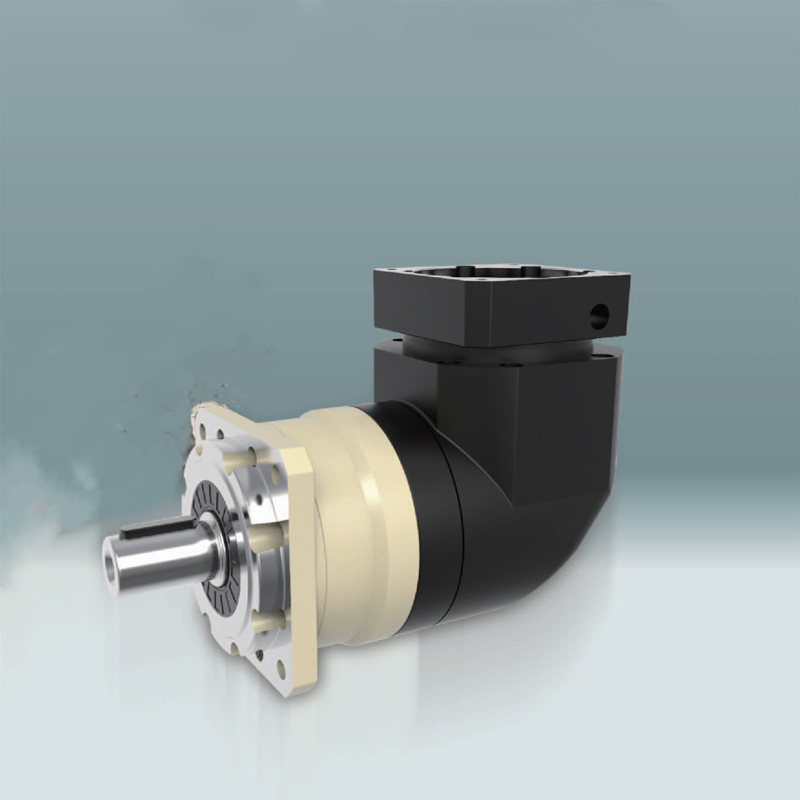

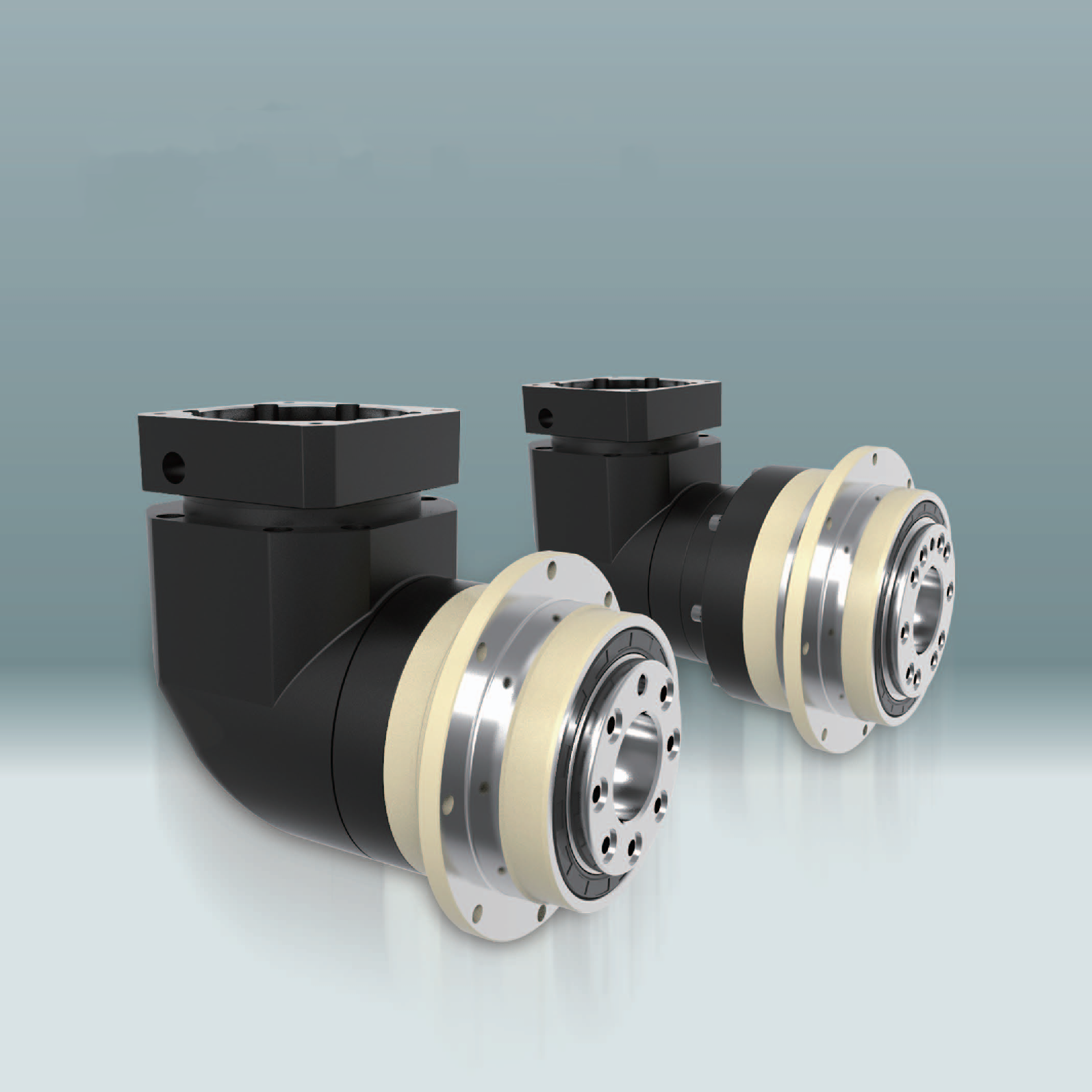

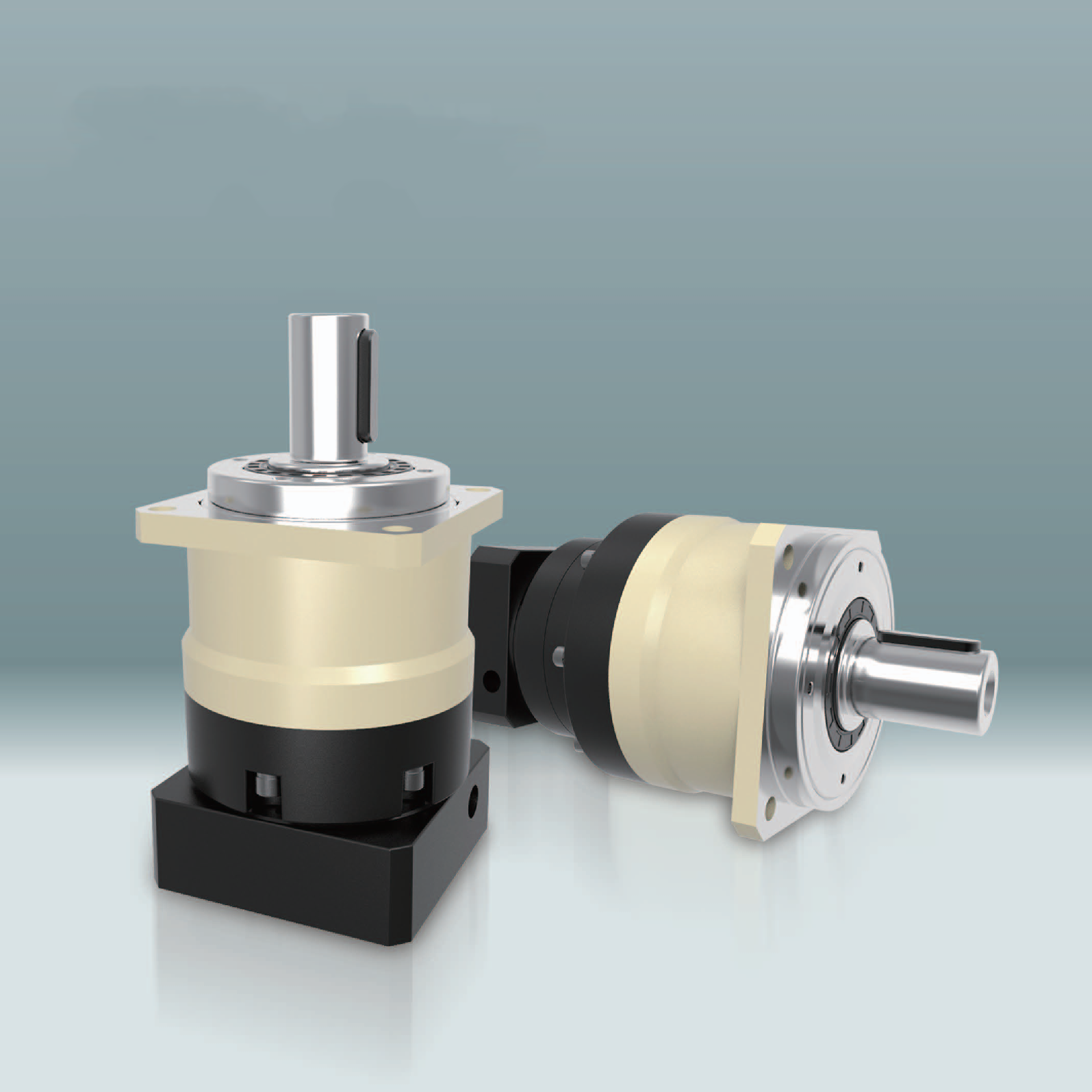

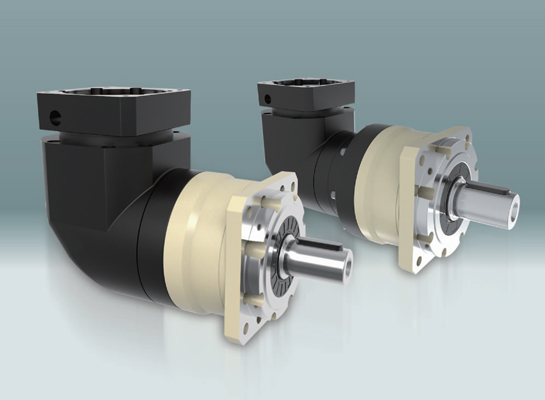

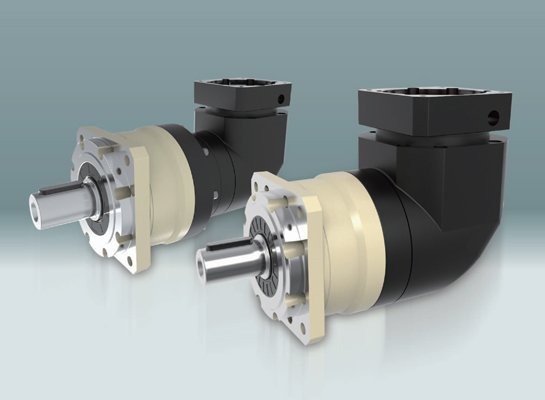

Product Display

Good stability

- Smooth operation: The symmetrical structure of the planetary gears balances the reaction forces acting on the center wheel and the planetary carrier bearing, reduces vibration and impact, ensures the stability of the reducer during operation, reduces noise and wear, and extends service life.

- High reliability: Through strict control of parts manufacturing and assembly process, as well as the selection of high-quality materials, the reducer has good fatigue resistance and durability.

Strong adaptability

- Multiple installation methods: usually with multiple installation methods such as foot installation, flange installation, torque arm installation, etc., can be selected according to different equipment requirements and installation conditions, convenient and flexible.

- Easy maintenance: The structure is relatively simple, the number of parts is small, and it is easy to disassemble and install, which is convenient for daily maintenance, such as changing lubricating oil, checking gear wear, etc.

Dimensions and interfaces

Quality Control

The company is equipped with advanced CNC lathes, milling machines, three-shift assembly production lines, and two-shift lathe and milling machine personnel.

Comprehensive quality inspection equipment such as gear profile inspection equipment, three-dimensional inspection, backlash, maximum invalid stroke, torsional rigidity, noise and vibration measurement machines, etc. We also have long-term cooperation and regularly audited outsourcing suppliers, so we are ready to take on large orders at any time and maintain stable quality.

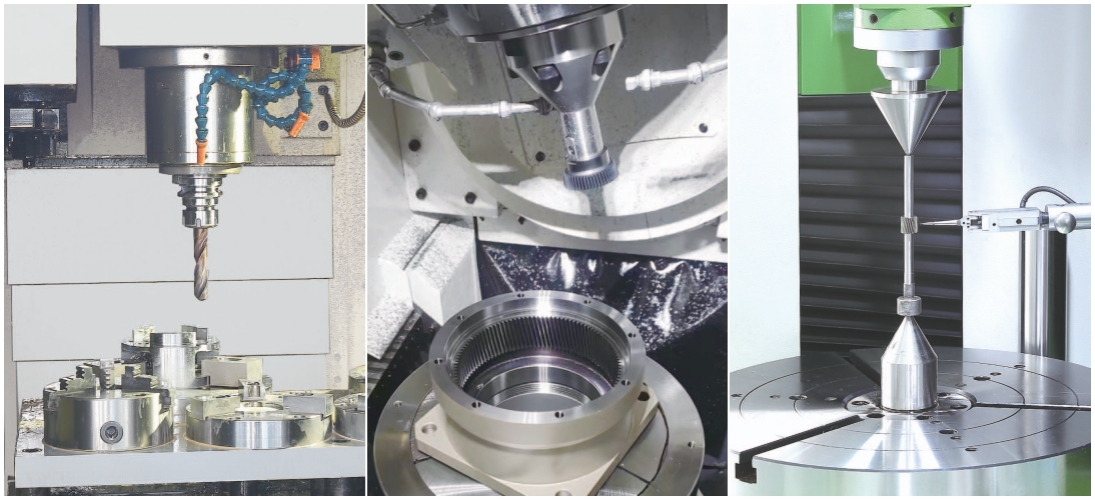

Application Cases

The products are widely used in CNC machine tools, cutting machines, welding machines, packaging and printing machinery, textile machinery, woodworking machinery, industrial robots and automated robotic arms, semiconductor equipment, fully automatic terminal machines, tool changers, aviation, medical equipment, etc.