Product Description

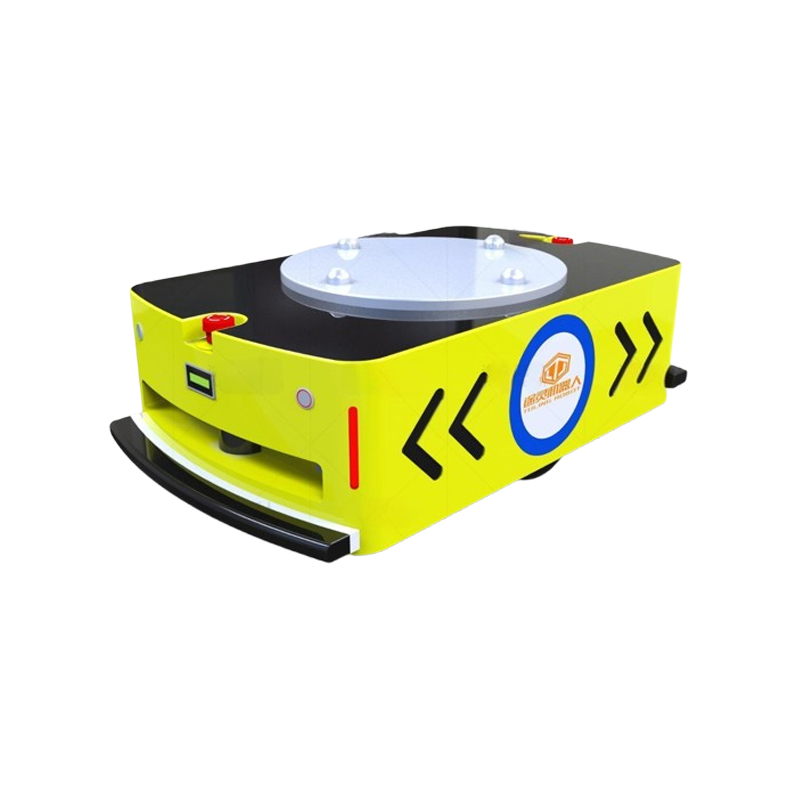

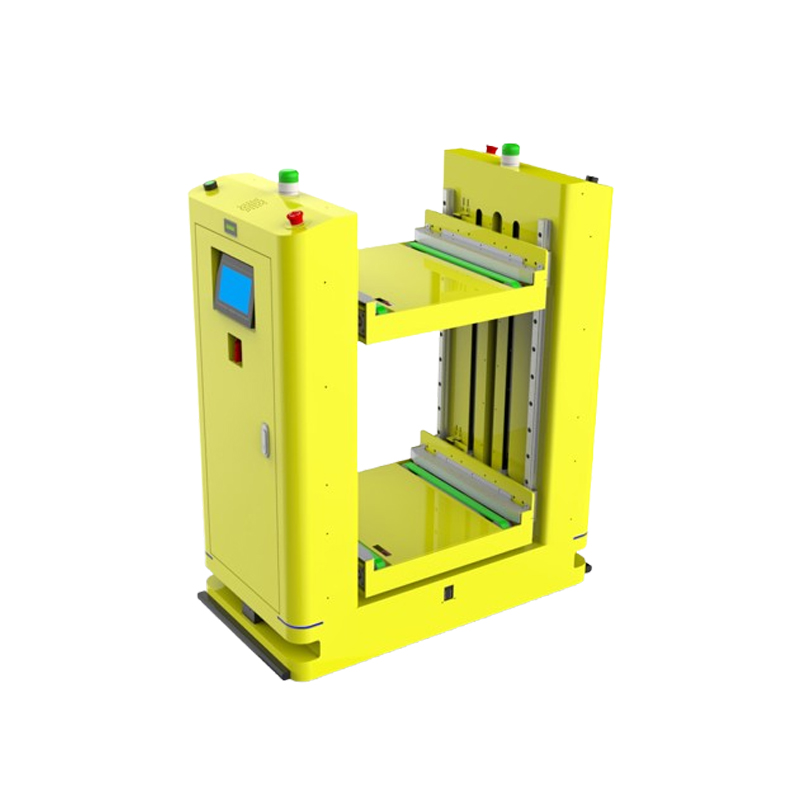

The backpack AGV ——TL-BF-430SX-002 is an advanced automated logistics and transportation equipment. It has a sturdy and compact body and a well-designed backpack platform. It has a strong carrying capacity and can easily carry a variety of materials. Integrating advanced navigation technologies such as laser, vision, and inertia, it can accurately locate, flexibly avoid obstacles, and quickly re-plan paths in complex industrial environments. The running speed can be adjusted as needed, and the acceleration and deceleration are smooth to ensure the safety of materials. Its intelligent control system can be seamlessly connected with MES and WMS to receive tasks, plan routes, and communicate smoothly when multiple units work together. It also has powerful fault diagnosis and early warning functions. It uses high-efficiency battery technology, fast charging, long battery life, and some support automatic charging. It is a powerful assistant to improve production and logistics efficiency and reduce costs.

Product Features

Single drive bidirectional operation, capable of multi-functional driving such as forward, backward, acceleration, deceleration, fork and turn, timed stop, and reversing operation;

Materials can be placed directly on the top of the AGV or loaded with material frames, roller platforms, etc., to automatically distribute production line materials, efficiently realize the turnover of workshop materials, and maximize the production efficiency of the enterprise;

In terms of navigation technology, it uses a combination of advanced laser navigation, visual navigation or inertial navigation and other navigation methods, which can be used in complex industrial environments. Whether it is a narrow passage, a busy production workshop, or a warehouse full of shelves, it can accurately find its own route. Its navigation system is highly flexible and can quickly re-plan the route according to changes in the on-site environment, easily avoid obstacles, and ensure the safety and smoothness of the transportation process.

Product parameters

| Performance parameters | Illustrate |

|---|---|

| Product model | TL-BF-430SX-002 |

| Dimensions | Standard L865mm*W500mm*H430mm/Total height 1095mm (or customized) |

| Navigation type | Magnetic navigation |

| Drive form | Differential drive |

| Walking mode | Multifunctional driving including forward, backward, fork and turn, timed stop, reversing operation, etc. |

| Walking speed | 0~40m/min(or customized) |

| Rated load | 150KG(or customized) |

| Climbing ability | ≤2° |

| Turning radius | 600mm |

| Stopping accuracy | ±10mm |

| Navigation accuracy | ±10mm |

| Battery life | 8-12H(or customized) |

| Charging method | Manual charging/automatic charging (optional) |

| Human-computer interaction | 4.3-inch touch screen |

| Alarm form | Voice and light alarm |

| Communication network | WIFI network/RF network |

| Power battery | 22AH lead-acid battery |

| Safety protection | Obstacle sensor + contact bumper + emergency stop button |

| Design life | >80000H |

Note: This AGV is a non-standard customized product. Please contact the merchant for price according to the customized size.

Customer Case

Tuling Robot debuts in Changhongqi

Backpack AGV is used in Huizhou electroplating industry

3C Electronics Industry-AGV Automatic Charging Case

Service

- Reliable quality and good stability

Before the products are shipped out of the factory, they will undergo strict EMC, temperature, humidity, vibration, life, stability and other aspects of inspection.

- Independent intellectual property rights

All AGV car control modules (software and hardware), mechanical structures, and mechanism module components are independently developed by Tuling Robotics and have applied for patent protection.

- High cost performance

The performance of the product reaches or exceeds that of imported products of the same grade, and the price is only one-third of imported products.

- After-sales guarantee

We have a strong after-sales technical team. If there are any problems after sales, the company will provide dedicated after-sales service 24 hours a day.

Pack

We are well aware that the safety of goods during transportation is of vital importance, so we have invested a lot of energy in packaging. Our professional packaging team will select the most suitable packaging materials according to the characteristics of the goods to minimize the damage of the products during transportation. Our product packaging is a solid fortress of safety and quality, escorting your purchasing experience.

Transport

We are committed to providing you with safe and efficient transportation services. During the transportation of products, we use professional packaging materials to ensure that the products are protected from bumps and damage. Whether it is land transportation or air transportation, we work with reliable logistics partners to monitor the transportation status in real time to ensure that the products are delivered to you on time and in good condition.